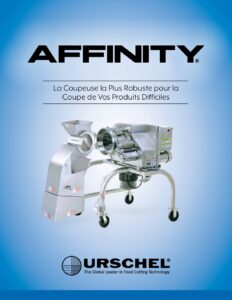

Affinity® Dicer

Robust, Heavy-Duty Dicer

The largest dicer in the Affinity® Series, explore the Affinity Dicer for high capacity output of difficult-to-cut products such as cheese, imitation cheese, soft meats, and high-fat or cold-temperature applications. Maintains positive feeding of difficult products to promote controlled, precision cutting.

-

Key Features

-

Applications

-

Specs

-

Knife Info

-

Types of Cuts

-

Media & Brochures

-

FAQs

Key Features

DIFFERENT MACHINE MODELS

Choose the right Affinity for your line: the U.S.D.A. (United States Department of Agriculture), Dairy Division accepted Affinity® Dicer, the Affinity® Dicer with built-in conveyor feed chute, or the Affinity® Dicer with built-in log precutter.

EASE OF SANITATION AND MAINTENANCE

U.S.D.A., Dairy Division accepted Affinity Dicer design incorporates food contact surfaces highly polished to an Ra 32 finish. Rounded tube frame and angled/rounded surfaces ease washdowns and deter bacterial growth. Hinged swingaway panels ease maintenance.

PROCESS DIFFICULT-TO-CUT PRODUCTS

The Affinity® Series features the ability to process high-fat, cold-temperature normally difficult-to-cut products, such as cheese, imitation cheese, meat/meat products, and sticky candied fruits.

SANITARY ZONE DESIGN

Sanitary design with all mechanical components completely separate from the food zone.

PRECISION, CONTROLLED CUTTING

The Affinity® Series feed roll and feed drum maintains positive feeding throughout the cutting stations to promote controlled, precision cutting.

HIGH CAPACITY PRODUCTION

High capacity capabilities and continuous operation for uninterrupted production.

HEAVY DUTY

Optional outboard bearing supports the cutting spindles to assist in the processing of tough, heavy-duty applications. Additional heavy-duty parts are also available.

URSCHEL SERVICE & SUPPORT

Urschel cutting machinery is backed by solid service and support. Urschel customer service is just as reliable and dependable as the rugged equipment Urschel manufactures.

Applications

Affinity® Dicer U.S.D.A., Dairy Division Accepted

The Affinity® Dicer (MAFF) U.S.D.A., Dairy Division accepted version has the ability to process high-fat, cold-temperature and otherwise normally difficult products. The feed roll and feed drum offer additional assistance transitioning product throughout the cutting zone. Sanitary stainless steel design. Food zone is completely separate from mechanical zone. Rounded tube frame limits microbial surface area and promotes self-draining. The dicer provides 2- or 3-dimensional cutting by adjusting the slice thickness, crosscut, and circular knife spindles for a full range of dices, crumbles/granulations, or strips. The Affinity accepts a wide range of infeed products in different shapes and sizes. Large infeed hopper accepts products up to 7″ (178 mm). It is ideal for dairy processing plants routinely inspected by the United States Department of Agriculture.

Affinity® Dicer with Conveyor Feed Chute

The Affinity® Dicer with built-in conveyor (MAFF) has the ability to process high-fat, cold-temperature, and otherwise normally difficult products. The built-in conveyor assists in feeding and orientation of product. The feed roll and feed drum offer additional assistance transitioning product throughout the cutting zone. Optional outboard bearing supports cutting spindles to assist with heavy-duty applications. Other heavy-duty parts are also available. Sanitary stainless steel design. Food zone is completely separate from mechanical zone. Rounded tube frame limits microbial surface area and promotes self-draining. The dicer provides 2- or 3-dimensional cutting by adjusting the slice thickness, crosscut, and circular knife spindles for a full range of dices, crumbles/granulations, or strips. The Affinity accepts a wide range of infeed products in different shapes and sizes. Large infeed hopper accepts products up to 7″ (178 mm), or up to 10″ (254 mm) maximum in largest single dimension depending on the product. Large product infeed combined with a powerful 25 HP (18 kW) motor achieves maximum capacity.

Affinity® Dicer with Built-in Precutter

The Affinity® Dicer (MAFF) with built-in precutter offers an all-in-one solution for processing of preformed meat logs. The feed roll and feed drum offer additional assistance transitioning product throughout the cutting zone. Optional outboard bearing supports cutting spindles to assist with heavy-duty applications. Other heavy-duty parts are also available. Sanitary stainless steel design. Food zone is completely separate from mechanical zone. Rounded tube frame limits microbial surface area and promotes self-draining. The dicer provides 2- or 3-dimensional cutting by adjusting the slice thickness, crosscut, and circular knife spindles for a full range of dices.

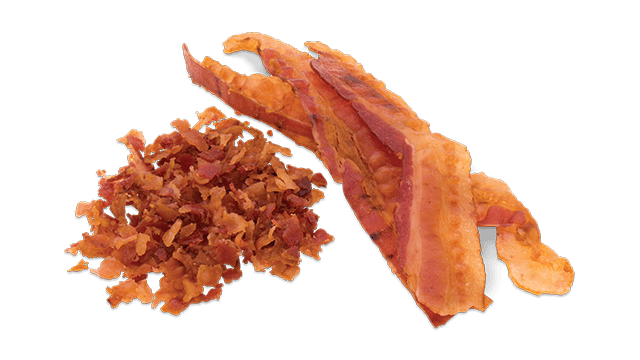

Bacon

1/4″ (6.4 mm)

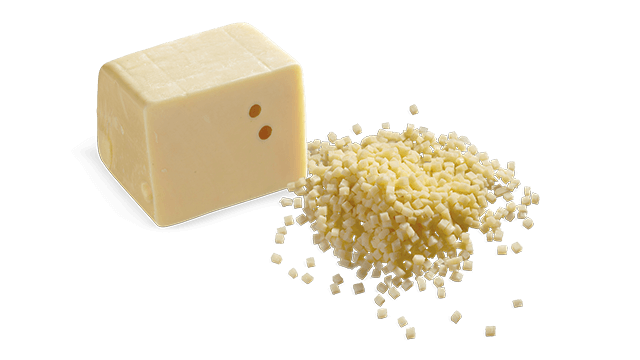

Swiss Cheese

1/8″ (3.2 mm) Dice

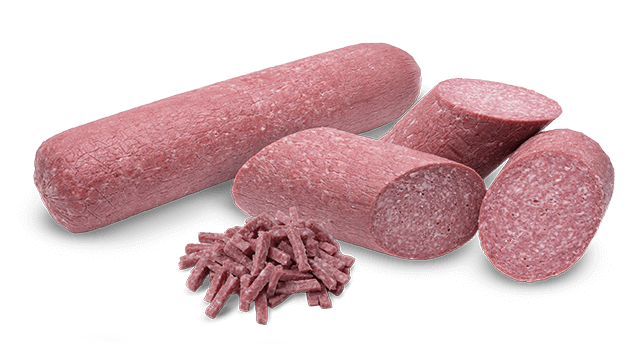

Salami

1/8 x 1 x 1/8″ (3.2 x 25.4 x 3.2 mm) Strip

Feta

1/2″ (12.8 mm) Crumble

Bacon

Crumble

Cranberry

1/8″ (3.2 mm) Strip

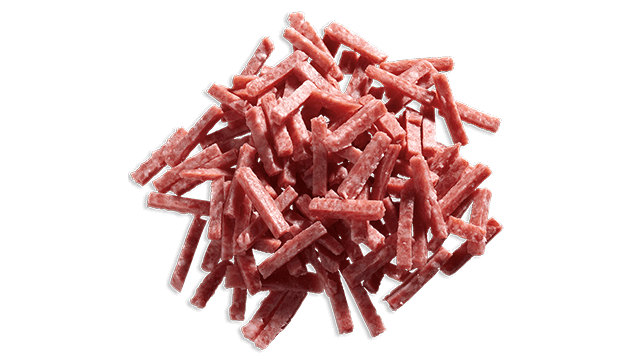

Salami

1/4 x 1/4 x 1-1/2″ (6.4 x 6.4 x 38.1 mm) Strip

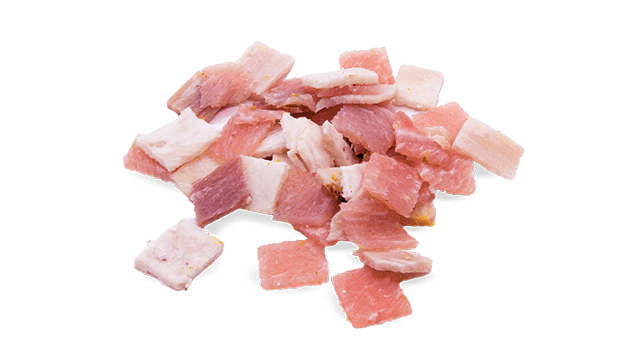

Ham

1/8″ (3.2 mm) Dice

Bacon

1/8 x 1/2 x 1/2″ (3.2 x 12.7 x 12.7 mm)

Pickle

3/16 x 1/8 x 5/32″ (4.7 x 3.2 x 3.9 mm)

Pot Roast

3/4 x 3 x 3/4″ (19.1 x 76.2 x 19.1 mm) Shred

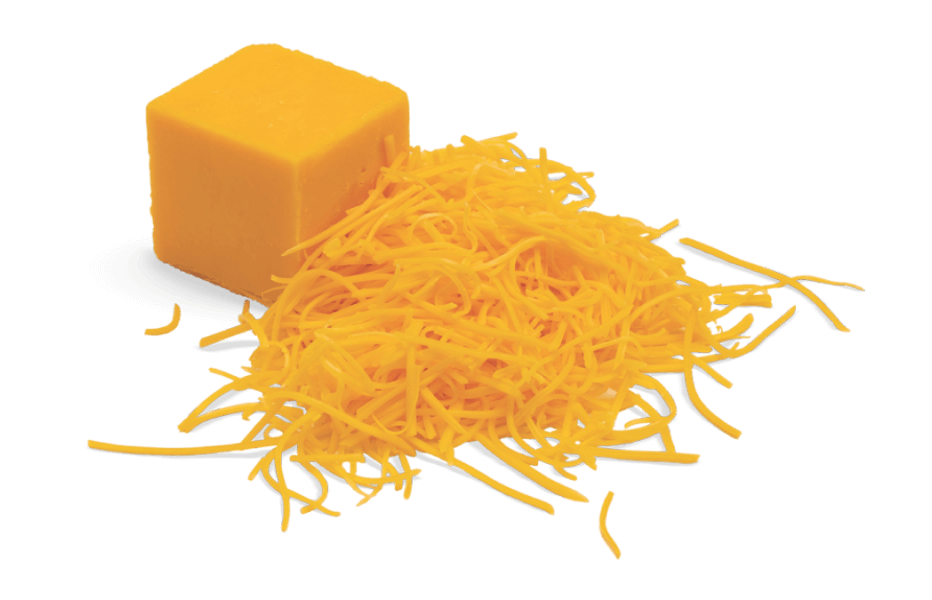

Cheddar

1/8 x 1/8 x 1-1/2″ (3.2 x 3.2 x 38.1 mm) Strip

Bread

1/2 x 1 x 1″ (12.7 x 25.4 x 25.4 mm)

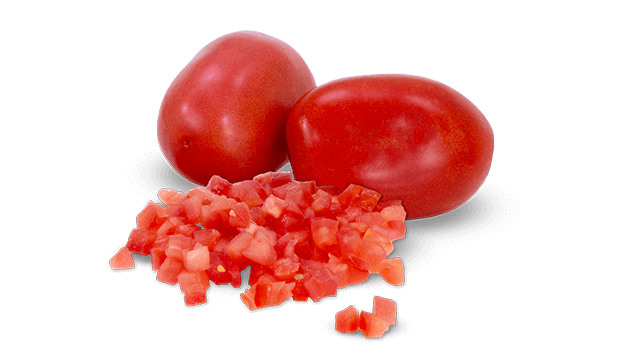

Tomato

1/4″ (6.4 mm) Dice

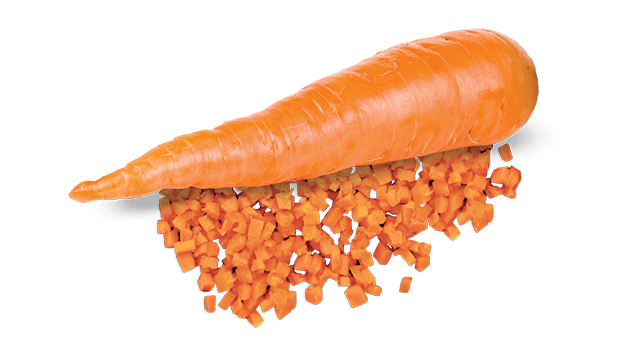

Carrot

1/8″ (3.2 mm) Dice

Cheddar

1/2″ (12.8 mm) Dice

White Cheddar Cheese

3/8 x 1-1/4 x 3/8″ (9.5 x 31.8 x 9.5 mm)

Cheddar

1/8″ (3.2 mm) Dice

Pet Food

1/8″ (3.2 mm) Dice

Poultry

1/2″ (12.8 mm) Dice

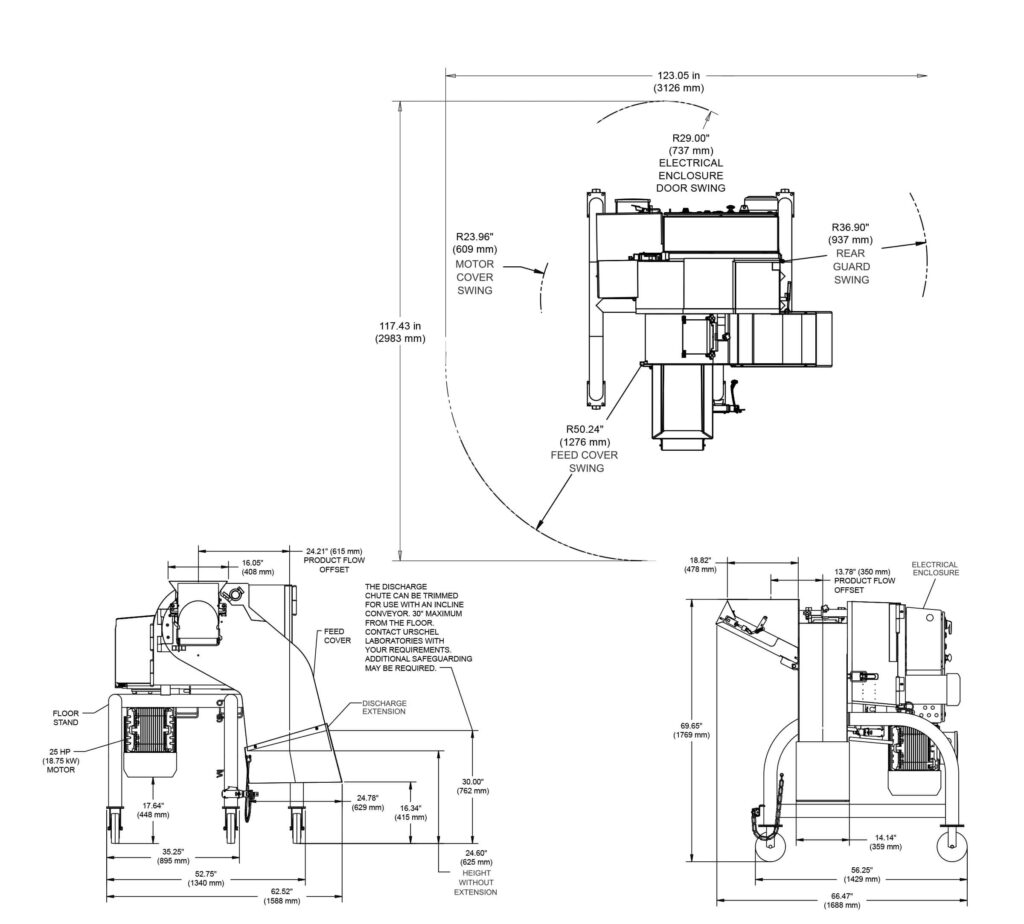

Specs

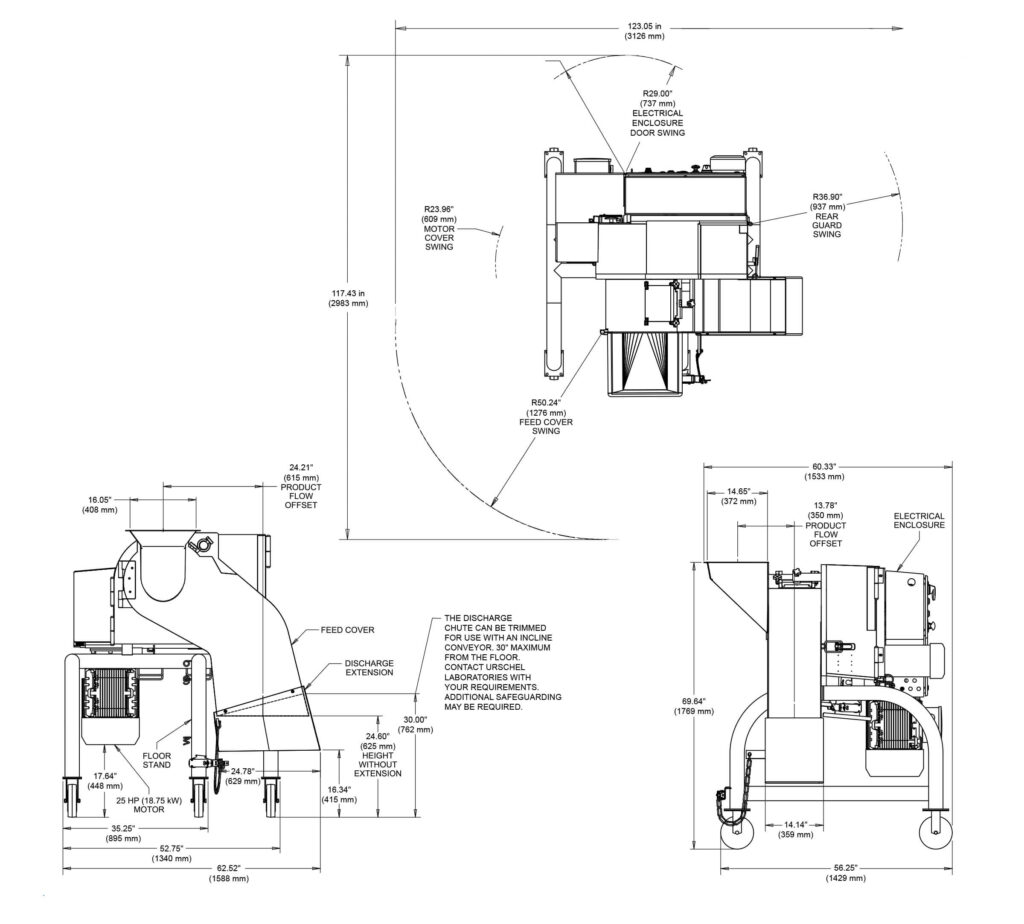

Affinity Dicer U.S.D.A., Dairy Division Accepted

| LENGTH | 60.33″ (1533 mm) |

| WIDTH | 62.52″ (1588 mm) |

| HEIGHT | 69.64″ (1769 mm) |

| NET WEIGHT | 2800 lb (1270 kg) |

| MOTOR | 25 HP (18 kW) |

| CROSSCUT KNIFE SPINDLE ASSEMBLY MOTOR | 5 HP (3.6 kW) |

Measurements and weights may vary depending on machine configuration.

Affinity Dicer with Built-in Conveyor Feed Chute

| LENGTH | 66.47″ (1688 mm) |

| WIDTH | 62.52″ (1588 mm) |

| HEIGHT | 69.65″ (1769 mm) |

| NET WEIGHT | 2800 lb (1270 kg) |

| MOTOR | 25 HP (18 kW) |

| CROSSCUT KNIFE SPINDLE ASSEMBLY MOTOR | 5 HP (3.6 kW) |

| INFEED CONVEYOR MOTOR | 1/6 HP (.12 kW) |

Affinity Dicer with Precutter

| LENGTH | 79.01″ (2007 mm) |

| WIDTH | 62.48″ (1587 mm) |

| HEIGHT | 82.16″ (2087 mm) |

| NET WEIGHT | 2025 lb (919 kg) |

| MOTOR | 25 HP (18 kW) |

| CROSSCUT KNIFE SPINDLE ASSEMBLY MOTOR | 5 HP (3.6 kW) |

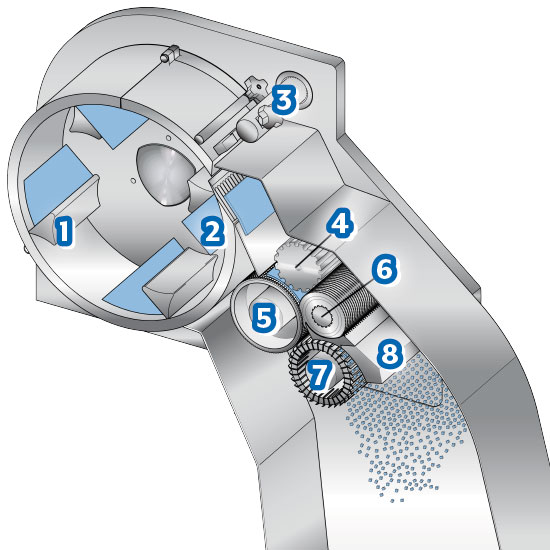

Operating Principle

Affinity® Dicer

- Impeller Paddles

- Slicing Knife

- Adjustable Slice Gate

- Feed Roll

- Feed Drum

- Circular Knives

- Crosscut Knives

- Stripper Plate

Knife Info

Affinity Dicer Slicing Knife

Slice adjustment dials and locks in the slice size.

2- or 3-dimensional cutting is accomplished by adjusting the slice thickness, crosscut, and circular knife spindles for a full range of dices, crumbles/granulations, or strips.

All-in-One Solution

Preformed Meat Logs

Affinity Dicer with precutter offers an all-in-one solution for processing preformed meat logs.

Heavy Duty

Robust Design

Optional outboard bearing supports heavy duty cutting spindle set-up to process tough, heavy-duty applications.

Controlled Positive Feeding

Feed Drum

Feed drum maintains positive feeding of sticky or moisture-rich products to promote controlled, precision cutting.

Cantilevered Cutting Spindles

Simplify Cleaning and Maintenance

Lightweight, cantilevered spindles remove completely from the machine for cleaning and maintenance.

Need Help with Knives for Your Urschel Cutting Machinery?

Contact us today to get help with upgrading or replacing your knives with original Urschel parts.

Types of Cuts

Cut Category

Slice

Slice thickness: 1/8 to 3/4” (3.2 to 19.1 mm)

Dice/Crumble/Strip

2 and 3-dimensional cutting involves adjusting the slice thickness and using the required circular or crosscut spindles.

Circular Knife Spindle: 1/8 to 3” (3.2 to 76.2 mm)

Crosscut Knife Spindle: 1/8 to 2” (3.2 to 50.8 mm)

Shred

Fine, medium, and coarse shreds can be produced on hot or chilled cooked meat products by using shredding disc spindle in place of the crosscut knife spindle.

Want to Test Cut Your Specific Product?

Contact Urschel to learn more about the product test cutting process.

Media & Brochures

Photography

Videos

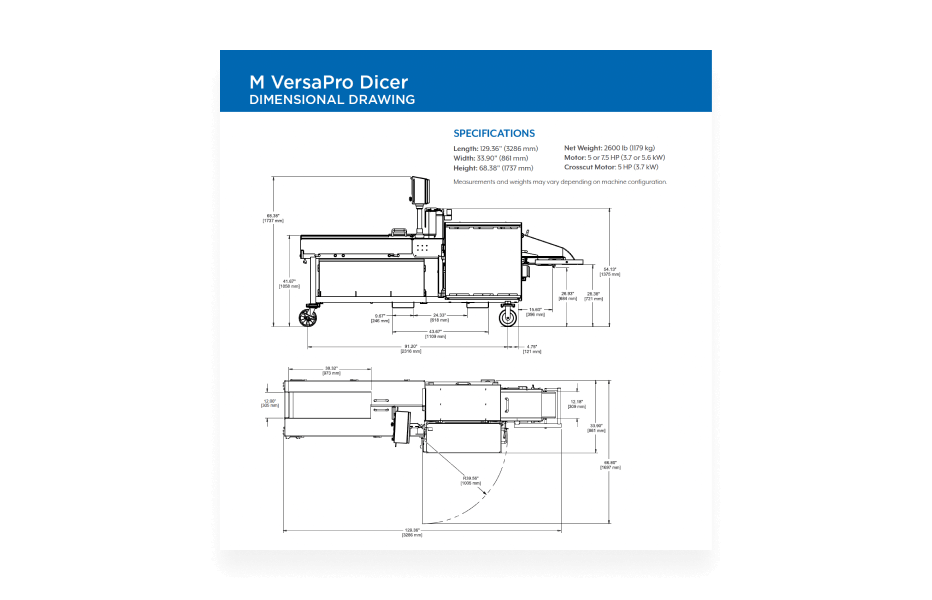

Dimensional Drawings

Frequently Asked Questions

Ask a Question

"*" indicates required fields

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Brochure Affinity® Dicer

Download (link opens in new window)

Brochure Affinity® Dicer (FR)

Download (link opens in new window)

Fact Sheet Affinity® Dicer with Conveyor

Download (link opens in new window)

Fact Sheet Affinity® Dicer with Conveyor (FR)

Download (link opens in new window)

Fact Sheet Affinity® Dicer with Conveyor (POL)

Download (link opens in new window)

Fact Sheet Affinity® Dicer with Conveyor (POR)

Download (link opens in new window)

Fact Sheet Affinity® Dicer

Download (link opens in new window)

Fact Sheet Affinity® Dicer (FR)

Download (link opens in new window)

Fact Sheet Affinity® Dicer (POL)

Download (link opens in new window)

Fact Sheet Affinity® Dicer (POR)

Download (link opens in new window)

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Brochure Affinity® Dicer

Download (link opens in new window)

Brochure Affinity® Dicer (FR)

Download (link opens in new window)

Fact Sheet Affinity® Dicer with Conveyor

Download (link opens in new window)

Fact Sheet Affinity® Dicer with Conveyor (FR)

Download (link opens in new window)

Fact Sheet Affinity® Dicer with Conveyor (POL)

Download (link opens in new window)

Fact Sheet Affinity® Dicer with Conveyor (POR)

Download (link opens in new window)

Fact Sheet Affinity® Dicer

Download (link opens in new window)

Fact Sheet Affinity® Dicer (FR)

Download (link opens in new window)

Fact Sheet Affinity® Dicer (POL)

Download (link opens in new window)

Fact Sheet Affinity® Dicer (POR)

Download (link opens in new window)

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.