M VersaPro® Dicer

The MVP Takes on Challenging Protein Applications

The MVP offers 33% increased feeding capacity versus the standard M6 due to wider belts, optimized cutting, and increased horsepower.

-

Key Features

-

Applications

-

Specs

-

Knife Info

-

Types of Cuts

-

Media & Brochures

-

FAQs

Key Features

SANITARY & VERSATILE

The M VersaPro® (MVP) Dicer provides the best in sanitary design and the ultimate in the versatile cutting of proteins.

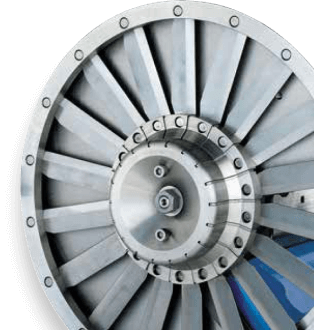

INTERCHANGEABLE KNIVES & SPACERS

5 or 6″ (127 or 152.4 mm) circular knives and spacers are interchangeable to provide expert cutting results.

INCREASED FEEDING CAPACITY

The MVP offers 33% increased feeding capacity versus the standard M6 due to wider belts, optimized cutting, and increased horsepower.

WIDER BELTS

Wider 12″ (304.8 mm) infeed and takeaway belts work together to provide even transitioning of product and prevention of product buildup. Takeaway belt facilitates discharging into totes.

IP69K CERTIFIED

IP69K certified electrical enclosure features a double-sealed door for extra protection during washdowns.

SANITARY DESIGN

The mechanical zone is isolated from the product zone to promote sanitation.

IMPROVED CUTTING METHOD

Patented, fluted crosscut option provides gentler cutting action. A deeper circular knife to feed drum penetration produces an improved cutting method.

AVAILABLE HMI OPTION

Available intuitive Allen-Bradley® touchscreen HMI option easily gathers data, monitors machine components including sensors and amperage; adjusts operating speeds, and saves recipes. Touchscreen swivels for full visibility.

Applications

Building on the Urschel Models M and M6, the M VersaPro® (MVP) Dicer provides the best in sanitary design and the ultimate in versatile cutting of proteins. Available with optional HMI (shown). The MVP offers 33% increased feeding capacity versus the standard M6 due to wider belts, optimized cutting, and increased horsepower. The belt-fed MVP delivers 2-dimensional dices, strips, or shreds from product of a predetermined thickness. The dicer offers infeed and takeaway belts to prevent product build-up. Takeaway belt facilitates discharging into totes. Ideally suited for cutting frozen-tempered, fresh-chilled, or hot-cooked beef, pork, protein alternatives, or poultry. Maximum input product size for firm products should not exceed 1.5″ (38.1 mm).

Chuck Roast

3/4″ (19.1 mm)

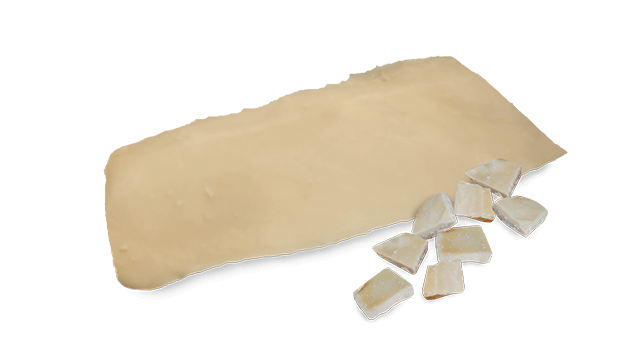

Alternative Protein Plank

1-1/2 x 1″ (38.1 x 25.4 mm)

Pork Skin

3/4 x 1-1/2″ (19.1 x 38.1 mm)

Chicken Breast

3/4″ (19.1 mm)

Cooked Chicken Breast

1/2″ (12.7 mm) Dice

Cooked Chicken Breast

3/8″ (9.5 mm) Strip

Alternative Protein

Shred

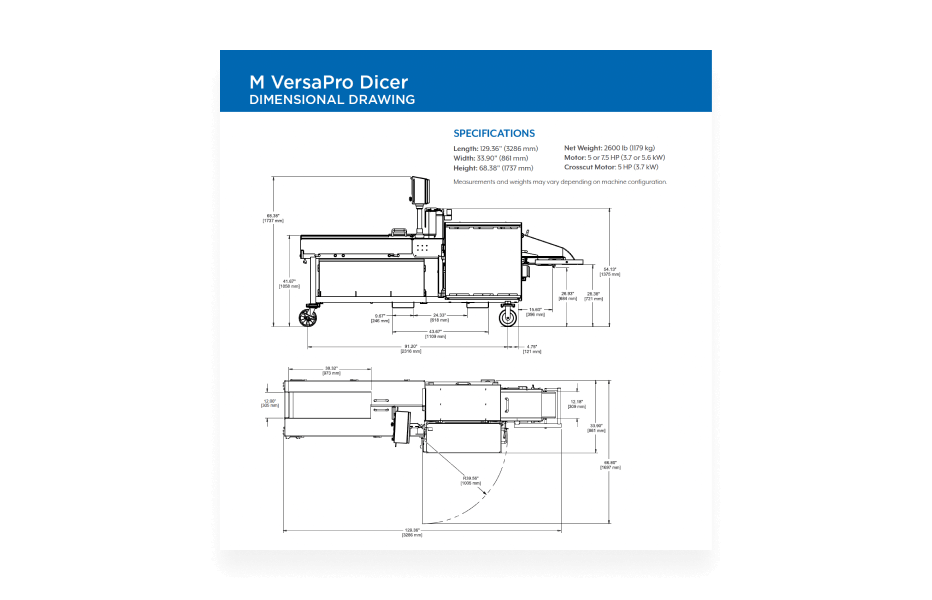

Specs

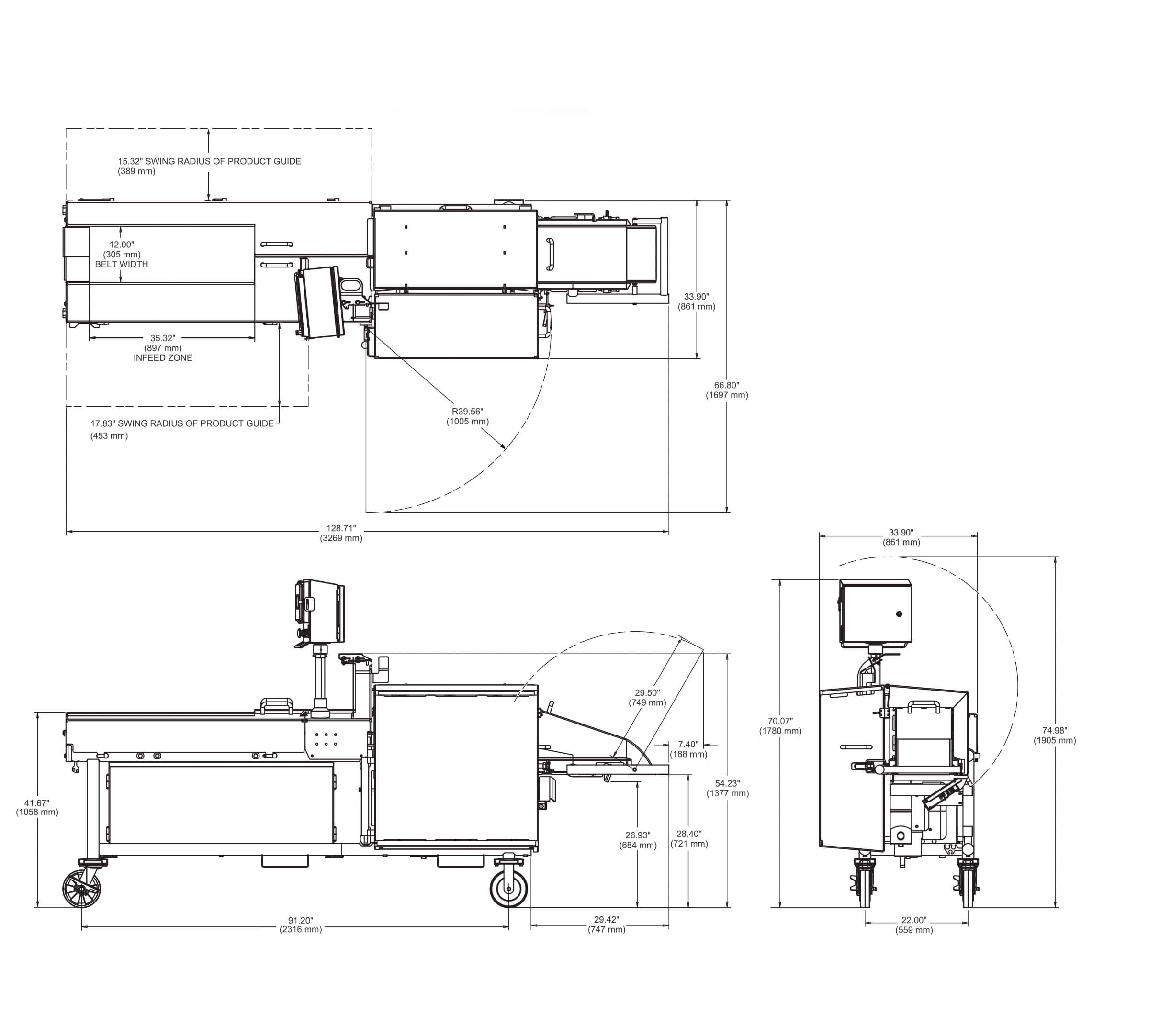

| LENGTH | 128.71″ (3269 mm) |

| WIDTH | 33.90″ (861 mm) |

| HEIGHT | 70.07″ (1780 mm) |

| NET WEIGHT | 2700 lb (1225 kg) |

| MOTOR | 5 or 10 HP (3.7 or 7.5 kW) |

| CROSSCUT MOTOR | 5 HP (3.7 kW) |

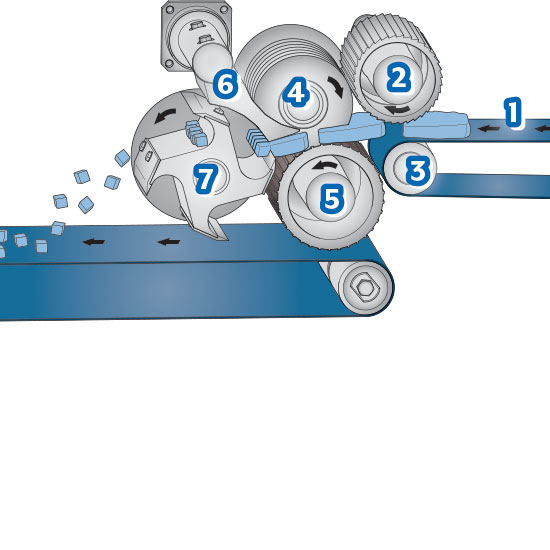

Operating Principle

M VersaPro® Dicer

- Feed Belt

- Feed Roll

- Drive Roll

- Circular Knives

- Feed Drum

- Stripper Plate

- Crosscut Knives (Patented Fluted Design Shown)

Knife Info

Need Help with Knives for Your Urschel Cutting Machinery?

Contact us today to get help with upgrading or replacing your knives with original Urschel parts.

Types of Cuts

Dice

Many sizes of cuts are possible by combining the various selections of circular knife spacings with different crosscut knife spindles.

Circular range: 3/16 to 1-1/2″ (4.8 to 38.1 mm)

Crosscut range: 1/8 to 3″ (3.2 to 76.2 mm) standard sizes, fully adjustable up to 5.5″ (140 mm) with variable speed crosscut motor.

Strip Cut

Strip cut a variety of widths by removing either the crosscut knife spindle assembly or the circular knife spindle assembly. The final thickness of the strip will be the same thickness as the original product.

Shred

To produce shreds from meat products, the crosscut knife spindle is replaced by a shredding spindle. The length of the shred can be controlled by orientation of the meat fibers of the incoming product and by the use of a circular knife spindle. Many variables can affect the final product; consult an Urschel representative for details.

Want to Test Cut Your Specific Product?

Contact Urschel to learn more about the product test cutting process.

Frequently Asked Questions

Ask a Question

"*" indicates required fields

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.