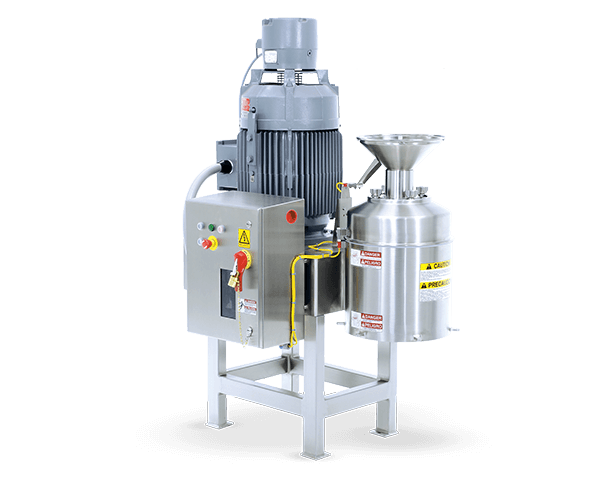

Comitrol® Processor Model 1700

Boundless Reduction Possibilities

Standard operations include comminuting, granulating, milling, flaking, slicing, liquefying, dispersing, and pureeing.

-

Key Features

-

Applications

-

Specs

-

Knife Info

-

Types of Cuts

-

Media & Brochures

-

FAQs

Key Features

ULTIMATE REDUCTION POTENTIALS

Standard operations include comminuting, granulating, milling, flaking, slicing, liquefying, dispersing, and pureeing.

SEALED ENCLOSURE

Deters escape of dust, vapor, and liquid when the Model 1700 is installed in conjunction with a collection system.

DRY & SEMI-DRY APPLICATION

Recommended for free-flowing dry and semi-dry applications.

UNINTERRUPTED PRODUCTION

Features continuous operation for uninterrupted production and simplified design to ease cleaning and maintenance.

VERSATILITY

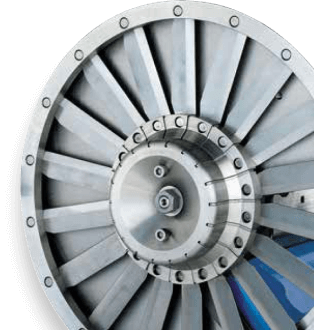

Accommodates all three styles of cutting heads: slicing head, microcut head, and cutting head.

HMI OPTION AVAILABLE

HMI benefits include: identifies misaligned sensors, soft start faults and fixes, total machine runtime, motor loads and overfeeding issues, and remote start/stop when connected to a control center.

Applications

The Comitrol® Processor Model 1700 offers the most versatility in the Comitrol line. It utilizes 6″ (152.4 mm) diameter reduction heads, available in the three different styles listed below. Product input is dependent on the style of reduction head, impeller selection, and spacing within the head. Generally, maximum input size in any dimension should not exceed:

Cutting Head: 2-1/2″ (63.5 mm)

Microcut Head & Slicing Head: 3/8″ (9.5 mm)

Sealed enclosure deters escape of dust, vapor, and liquid when the Comitrol Processor is installed in conjunction with a collection system. Stainless steel construction ensures maximum durability and sanitation. The machine features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance.

HMI Option Available

HMI benefits include: identifies misaligned sensors, soft start faults and fixes, total machine runtime, motor loads and overfeeding issues, and remote start/stop when connected to a control center.

Acai

Granulation

Almond

Coarse Butter

Almond

Flour

Beef Jerky

Crumble

Bentone Clay Based Grease

Mill

Black Pepper

Powder

Blueberry

Puree

Broccoli

Rice

Cannabis

Powder

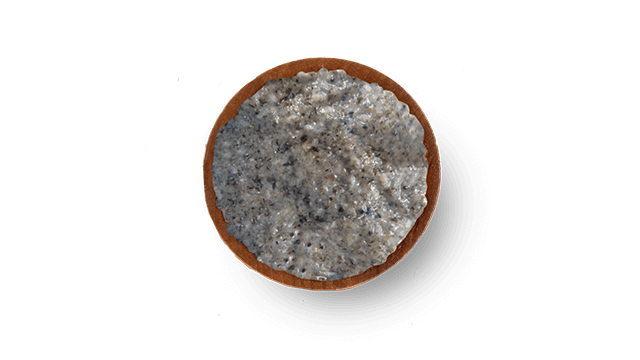

Cashew

Butter

Chili Pepper

Coarse and Fine Puree

Coconut

Milk

Coconut Yogurt

Puree

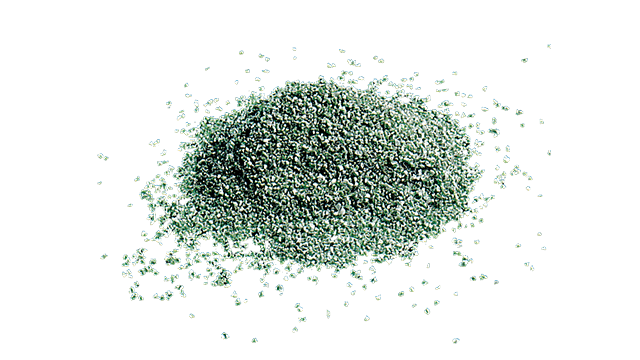

Coffee Bean

Granulation

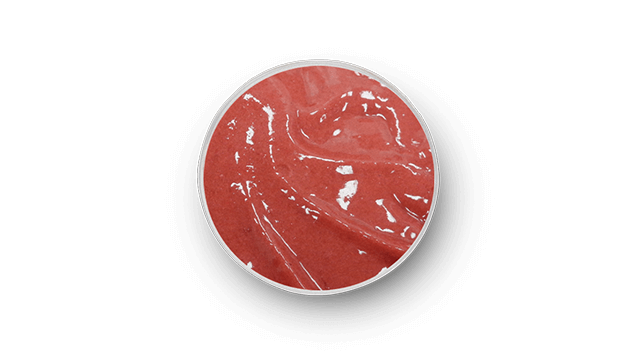

Cooked Beef

Slurry

Cranberry

Puree

Gelantinized Corn Starch

Powder

Ginger

Granulation

Ginger

Paste

Granola

Granulation

Hazelnut

Flake

Hummus

Puree

Insect

Paste

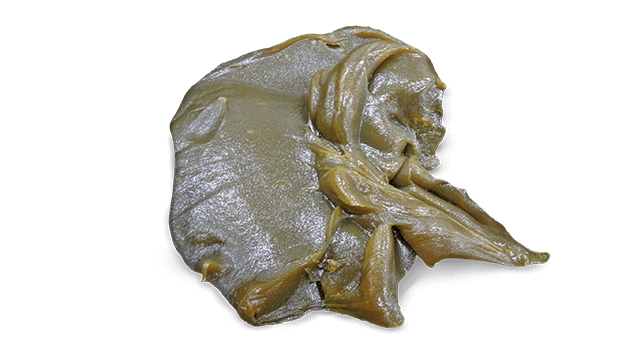

Kale

Puree

Parmesan Cheese

Granulation

Pea Protein Extrusion

Flake

Pineapple

Coarse and Fine Puree

Raspberry

Puree

Rubber Flooring

Reduction

Seaweed

Flake

Sunflower Seed

Butter

TVP

Reduction

Vanilla Bean

Granulation

Wafer Cookie

Granulation

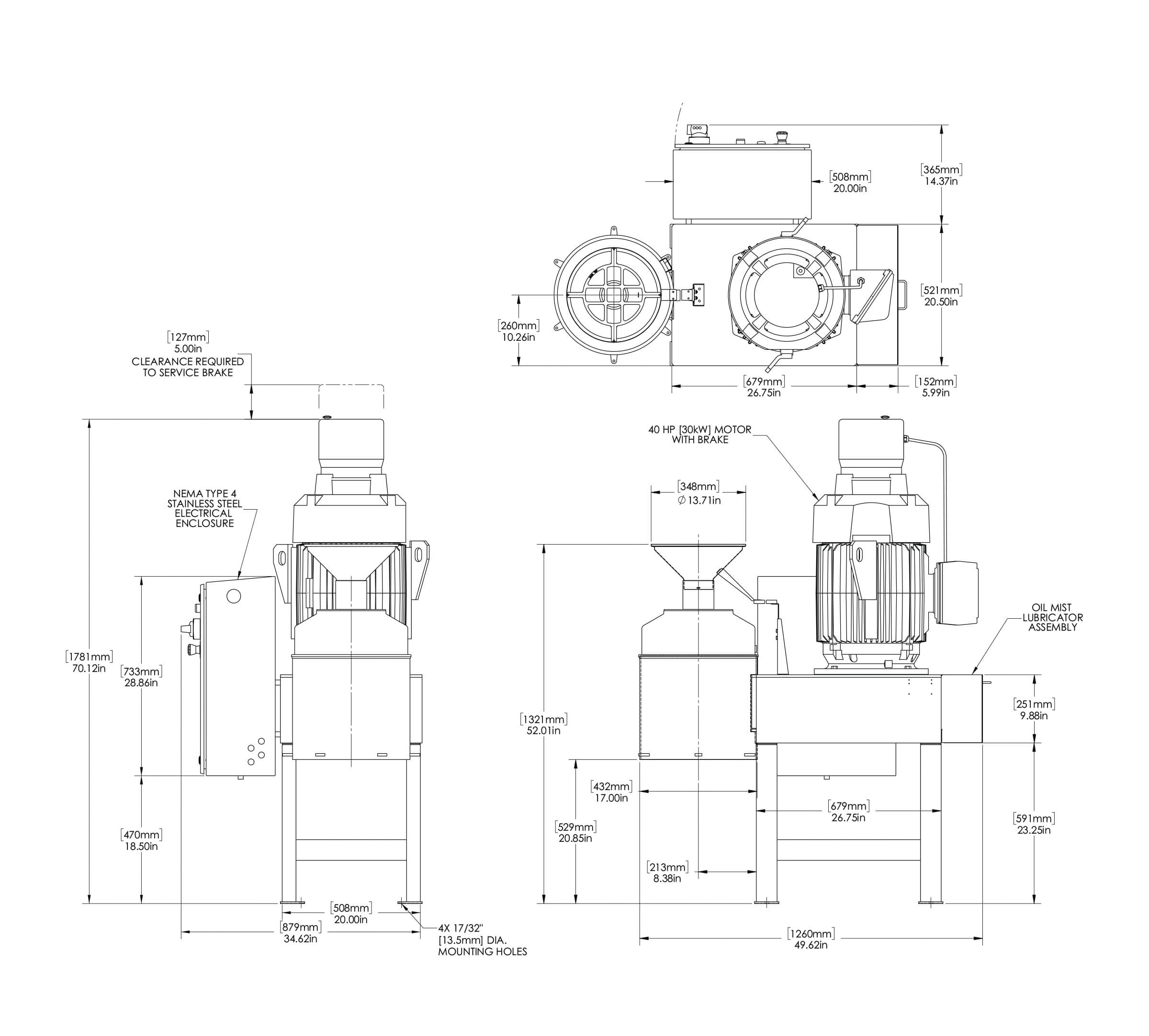

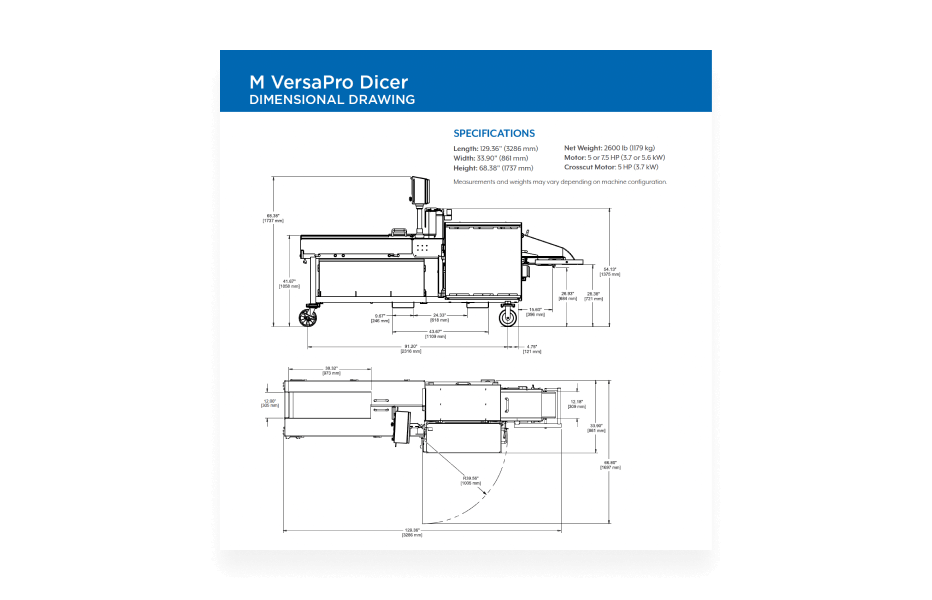

Specs

| LENGTH | 49.62″ (1260 mm) |

| WIDTH | 34.62″ (879 mm) |

| HEIGHT | 70.12″ (1781 mm) * |

| NET WEIGHT | 1100 lb (499 kg) |

| MOTOR | 15, 30, or 40 HP (11.2, 22.4, or 30 kW) |

*Usual height with 40 HP motor is shown.

Measurements and weights may vary depending on machine configuration.

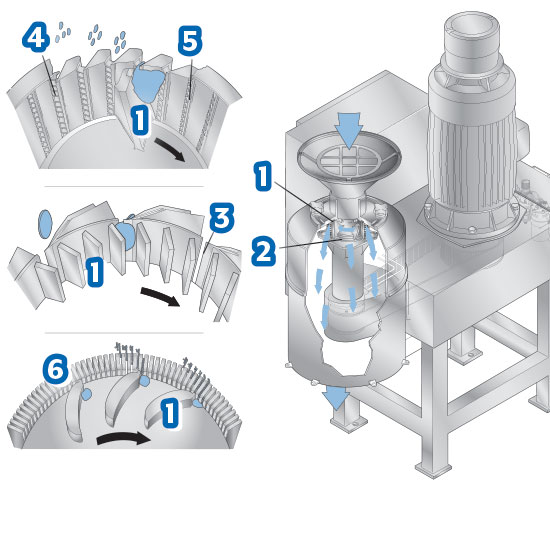

Operating Principle

Comitrol® Processor Model 1700

- Impeller

- Reduction Head

- Slicing Knife

- Horizontal Separators

- Vertical Knives

- Blades

Knife Info

Need Help with Knives for Your Urschel Cutting Machinery?

Contact us today to get help with upgrading or replacing your knives with original Urschel parts.

Types of Cuts

Slicing Head

Slices: .020 to .060″ (.5 to 1.5 mm).

Cutting Head

Offers particle size from .010 to 1.5″ (.254 to 38.1 mm).

Microcut Head

Offers the smallest in particle size from .0012 to .0237″ (.03 to .6 mm).

Note: Products that are explosive or create a potentially explosive atmosphere should not be processed by any standard Urschel machine. A potentially explosive atmosphere could be created if processing your product creates fumes or dust in sufficient concentrations. In such cases, customers may work with Urschel to develop a customized solution through a certified print (CP) process.

Want to Test Cut Your Specific Product?

Contact Urschel to learn more about the product test cutting process.

Frequently Asked Questions

Ask a Question

"*" indicates required fields

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.