Comitrol® Processor Models 3600 – 3675SL

Coarse to Smooth Puree

Processors benefit from a wide selection of interchangeable cutting heads and impellers for diverse applications such as chopping, flake cutting, granulating, pureeing, and emulsifying.

-

Key Features

-

Applications

-

Specs

-

Knife Info

-

Types of Cuts

-

Media & Brochures

-

FAQs

Key Features

COMMON APPLICATIONS

Common applications include rework of bakery items, beef/poultry/seafood and byproducts, and vegetables/fruits.

UNINTERRUPTED PRODUCTION

Features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance.

LOW TO HIGH CAPACITY PRODUCTION

The Comitrol Processor Models 3600, 3640, 3660, and 3675 are designed for low to high capacity production environments.

INTERCHANGEABLE CUTTING HEADS

Processors benefit from a wide selection of interchangeable cutting heads and impellers for diverse applications such as chopping, flake cutting, granulating, pureeing, and emulsifying.

Applications

Comitrol® Processor Model 3600 Slant

The Model 3600 Slant is popular in both small volume and large-scale production environments. The 3600 Slant is equipped with a 10 HP (7.5 kW) impeller motor for speeds up to 3600 RPM. The gravity fed machine offers a compact size. The machine is often used as a pre-cutter in conjunction with a Comitrol Processor Model 1500 or 1700. Common applications include rework of bakery items, beef/poultry/seafood and byproducts, and vegetables/fruits.

Stainless steel construction ensures maximum durability and sanitation. The machine features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance. Product input is dependent on the style of reduction head, impeller selection, and spacing within the head. Generally, maximum input size in any dimension should not exceed 2-1/2″ (63.5 mm).

Comitrol® Processor Slant Models 3640, 3660, and 3675

The Comitrol® Processor Slant Models 3640, 3660, and 3675 are ideal for small or high output food processing plants. Each slant model offers a different size motor tailored to production requirements. Processors benefit from a wide selection of interchangeable cutting heads and impellers for diverse applications such as chopping, flake cutting, granulating, pureeing, and emulsifying.

These models are frequently utilized as precutters for further reduction by a Comitrol Model 1500 or 1700. Stainless steel construction ensures maximum durability and sanitation. Machines feature continuous operation for uninterrupted production, and are designed for easy cleanup and maintenance. Product input is dependent on the style of reduction head, impeller selection, and spacing within the head. Generally, maximum input size in any dimension should not exceed 2-1/2″ (63.5 mm).

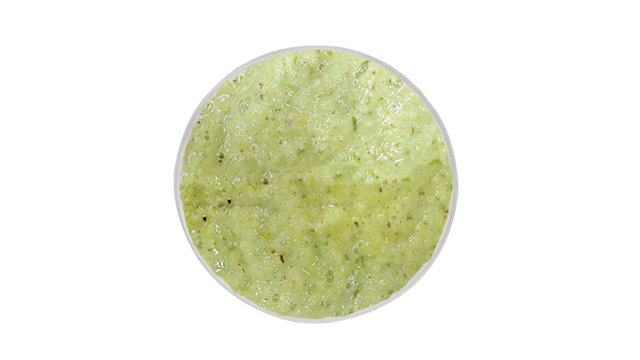

Avocado

Paste

Bread

Granulate

Pineapple

Coarse Puree

Cracker

Coarse Puree

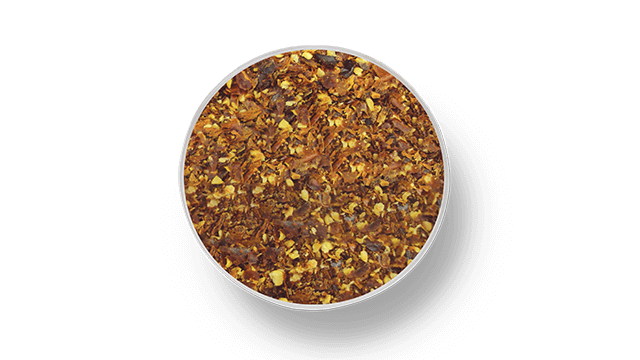

Dried Chili Pepper

Flake

Dried Citrus Peel

Rework

Fish Waste

Emulsion

Flour Tortilla Shell

Reduction

Garlic

Puree

Granola

Granulate

Granola/Fruit/Nut Mixture

Reduction

Kale

Puree

Peach

Puree

Peanut Butter Cracker

Rework

Polymer

Reduction

Salsa

Reduction

Sandwich Cookie

Rework

Tomatillo/Onion

Puree

Coconut

Desiccated

Specs

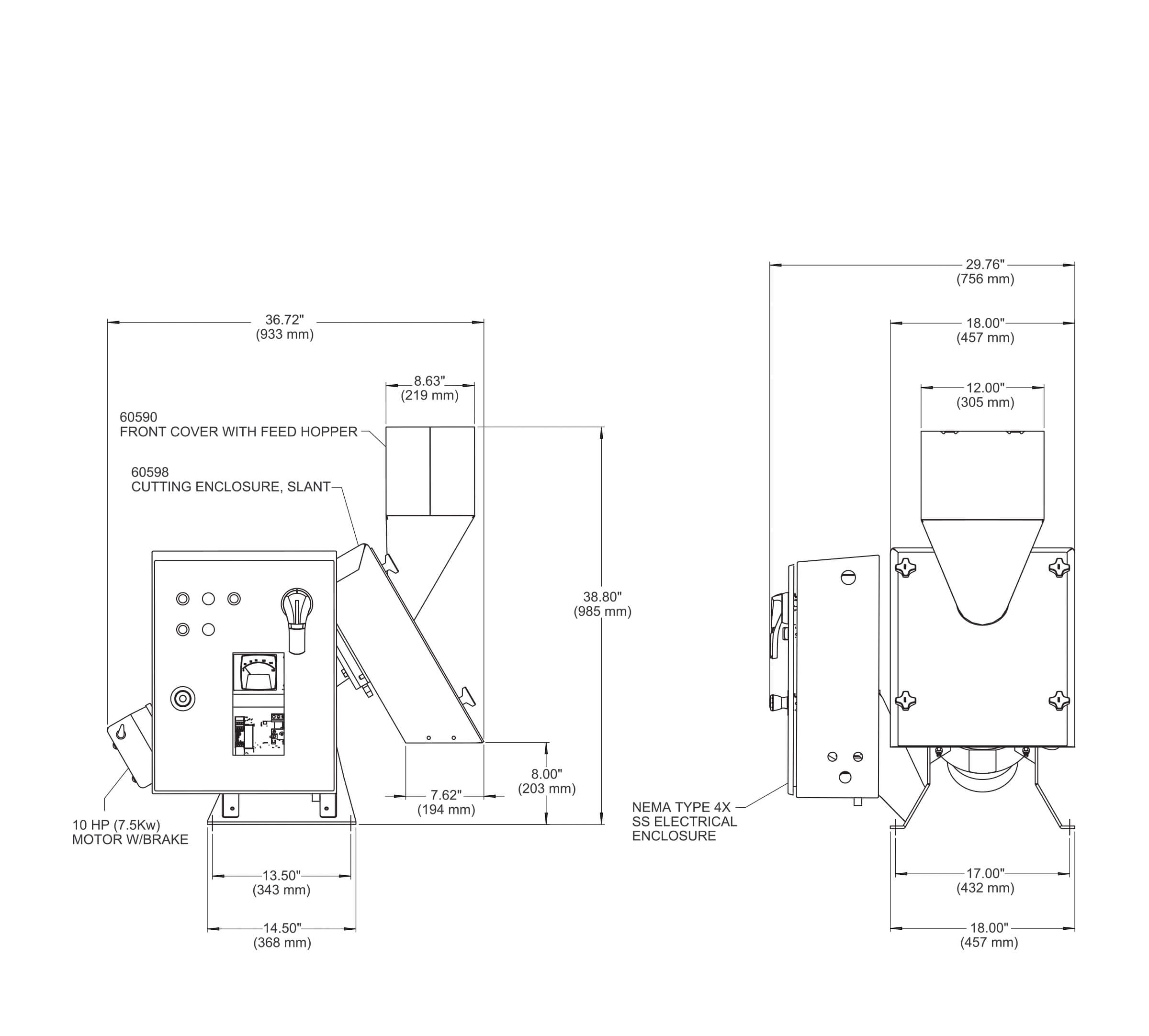

Comitrol® Processor Slant Model 3600

| LENGTH | 36.72″ (933 mm) |

| WIDTH | 29.76″ (756 mm) |

| HEIGHT | 38.80″ (985 mm) |

| NET WEIGHT | 400 lb (181 kg) |

| IMPELLER MOTOR | 10 HP (7.5 kW) |

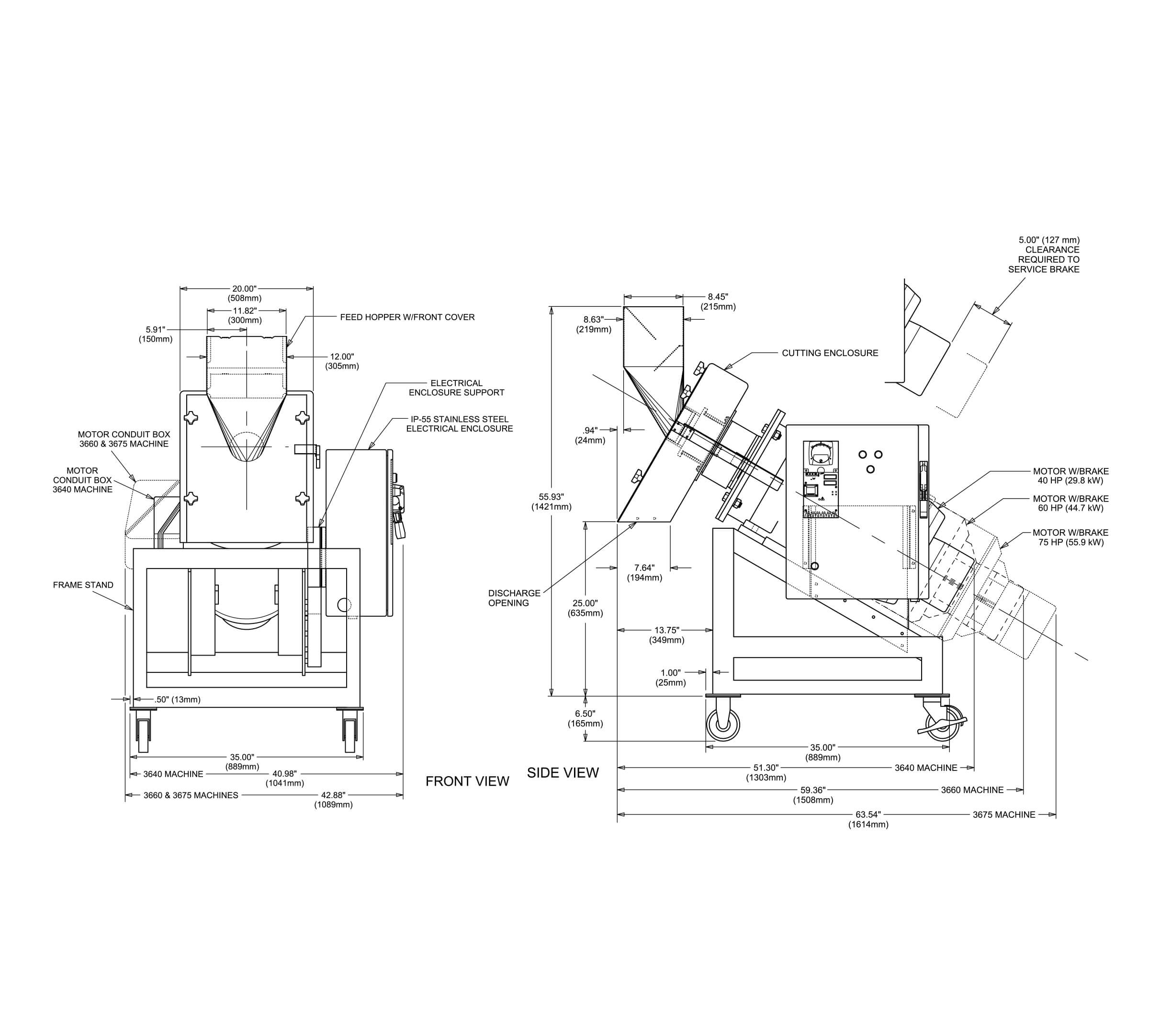

Comitrol® Processor Slant Model 3640

| LENGTH | 51.30″ (1303 mm) |

| WIDTH | 40.98″ (1041 mm) |

| HEIGHT | 62.43″ (1586 mm) |

| NET WEIGHT | 1196 lb (542 kg) |

| IMPELLER MOTOR | 40 HP (29.8 kW) |

Comitrol® Processor Slant Model 3660

| LENGTH | 59.36″ (1508 mm) |

| WIDTH | 42.88″ (1089 mm) |

| HEIGHT | 62.43″ (1586 mm) |

| NET WEIGHT | 1400 lb (636 kg) |

| IMPELLER MOTOR | 60 HP (44.8 kW) |

Comitrol® Processor Model Slant 3675

| LENGTH | 63.54″ (1614 mm) |

| WIDTH | 42.88″ (1089 mm) |

| HEIGHT | 62.43″ (1586 mm) |

| NET WEIGHT | 1500 lb (681 kg) |

| IMPELLER MOTOR | 75 HP (56.0 kW) |

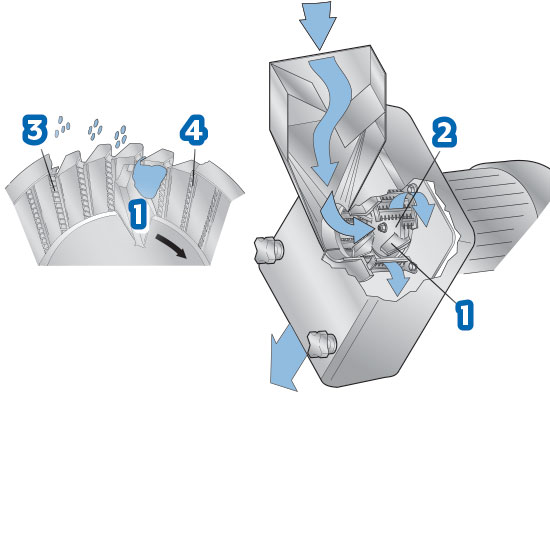

Operating Principle

Comitrol® Processor Model 3600 – 3675SL

- Impeller

- Cutting Head

- Horizontal Separators

- Vertical Knives

Knife Info

Need Help with Knives for Your Urschel Cutting Machinery?

Contact us today to get help with upgrading or replacing your knives with original Urschel parts.

Types of Cuts

Cutting Head

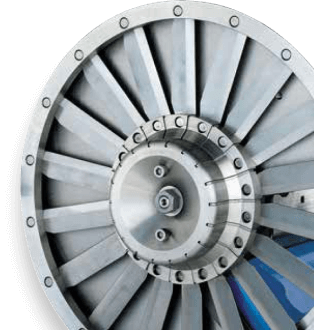

Utilizes 6″ (152.4 mm) diameter Cutting Heads paired with a variety of impellers to produce coarse to fine reductions.

Note: Products that are explosive or create a potentially explosive atmosphere should not be processed by any standard Urschel machine. A potentially explosive atmosphere could be created if processing your product creates fumes or dust in sufficient concentrations. In such cases, customers may work with Urschel to develop a customized solution through a certified print (CP) process.

Want to Test Cut Your Specific Product?

Contact Urschel to learn more about the product test cutting process.

Media & Brochures

Photography

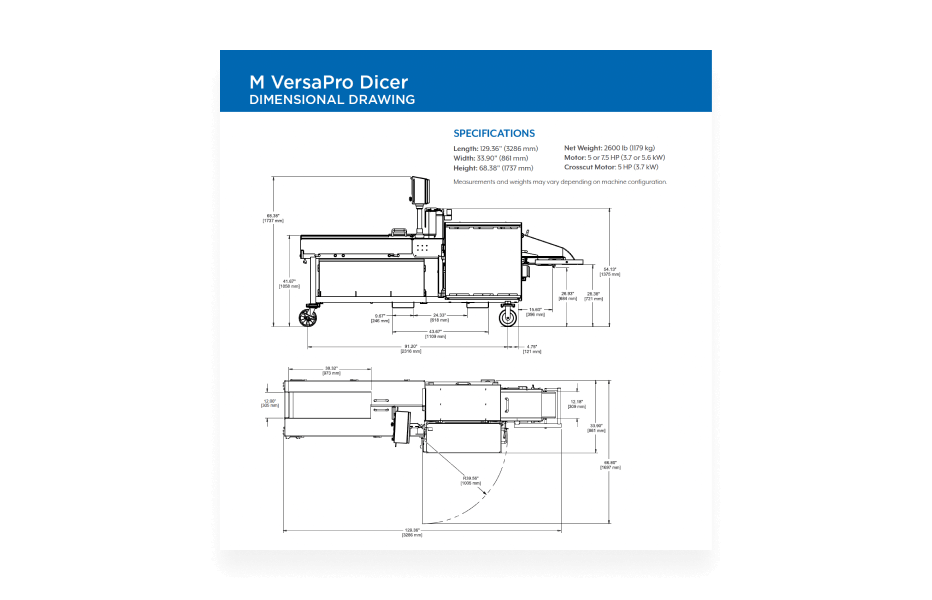

Dimensional Drawings

Frequently Asked Questions

Ask a Question

"*" indicates required fields

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Fact Sheet Comitrol® Processor Model 3600SL

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3640SL-3675SL

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3600SL (FR)

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3640SL-3675SL (FR)

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3600SL (POR)

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3640SL-3675SL (POR)

Download (link opens in new window)

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Fact Sheet Comitrol® Processor Model 3600SL

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3640SL-3675SL

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3600SL (FR)

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3640SL-3675SL (FR)

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3600SL (POR)

Download (link opens in new window)

Fact Sheet Comitrol® Processor Model 3640SL-3675SL (POR)

Download (link opens in new window)

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.