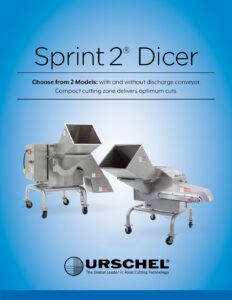

Sprint 2® Dicer

High Performance Food Dicer

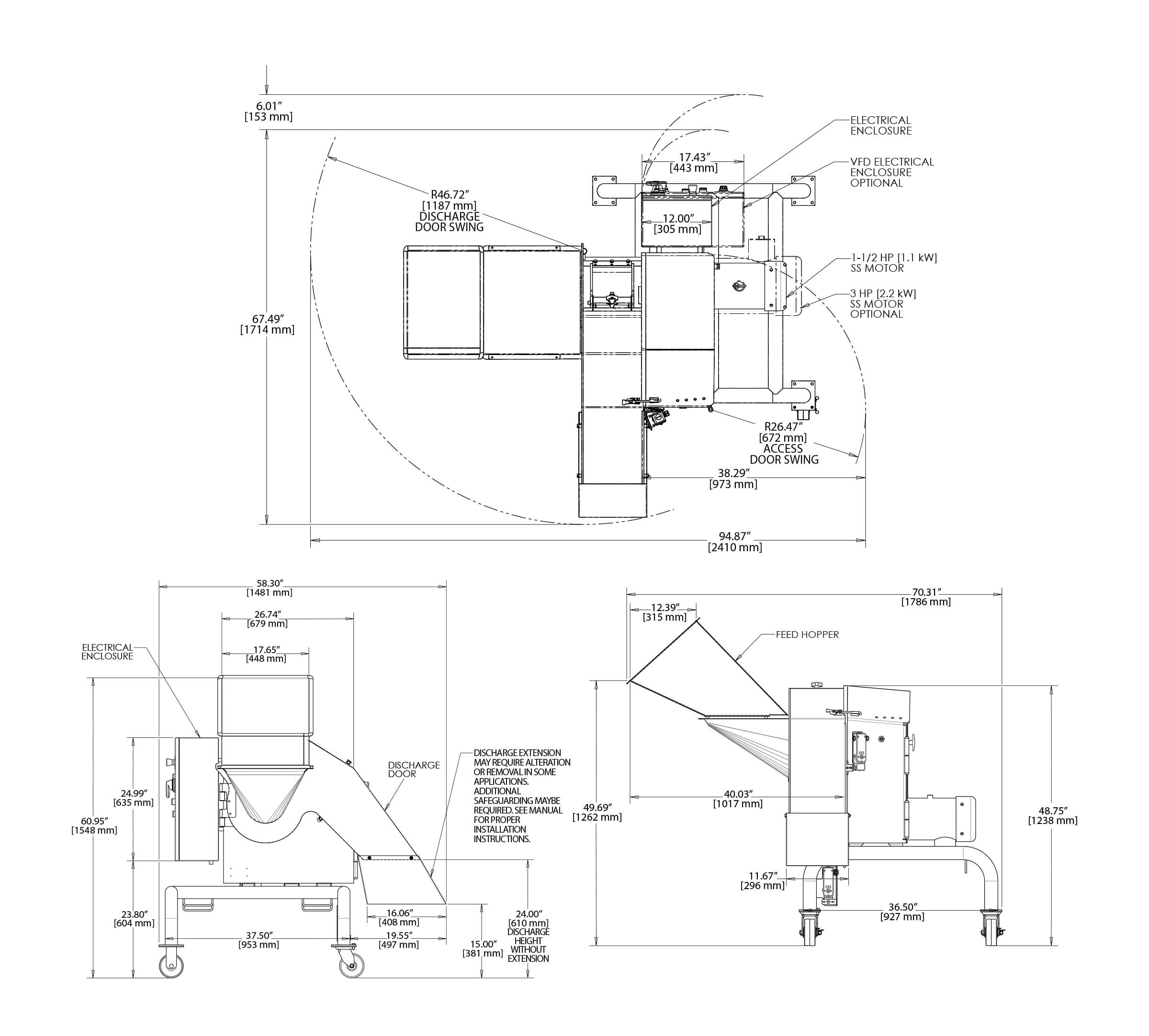

Compact cutting zone delivers precision cuts. Available with built-in conveyor discharge to facilitate dispensing into totes. Select a 1.5 HP (1.1 kW) or 3 HP (2.2 kW) motor.

-

Key Features

-

Applications

-

Specs

-

Knife Info

-

Types of Cuts

-

Media & Brochures

-

FAQs

Key Features

DIFFERENT MACHINE MODELS

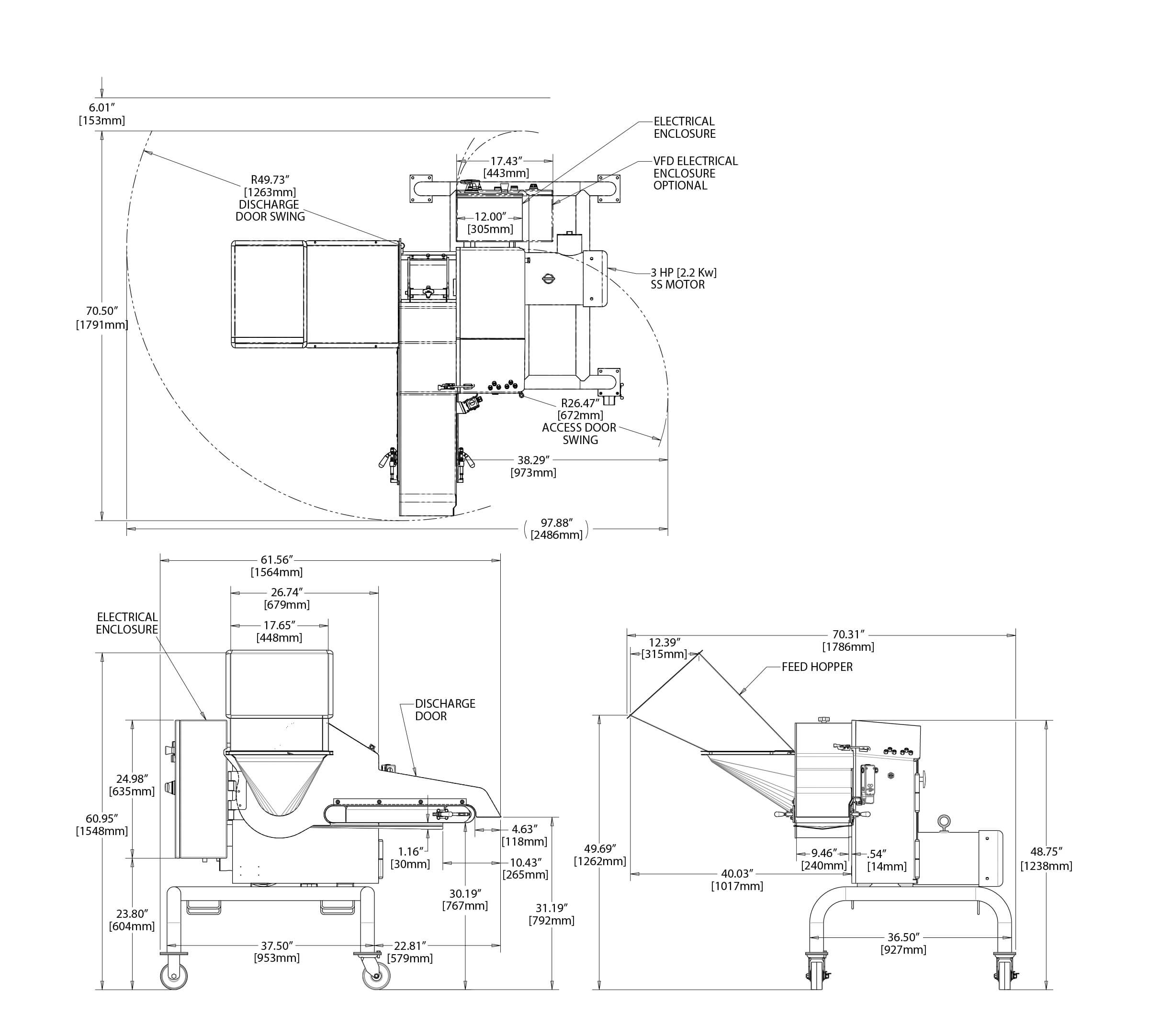

Choose the right Sprint 2 for your line: the standard Sprint 2 Dicer or the Sprint 2 with built-in Discharge Conveyor.

EASE OF SANITATION AND MAINTENANCE

Stainless steel construction with sloped surface areas to deter bacterial growth. Hinged access panels promote sanitation and ease of maintenance.

MOTOR CHOICES

Sprint 2 Dicer available stainless steel motor options include: 3 HP (2.2 kW) motor equipped with VFD (variable frequency drive), 3 HP (2.2 kW) soft start motor, or 1.5 HP (1.1 kW) soft start motor.

SANITARY ZONE DESIGN

Sanitary design with all mechanical components completely separate from the food zone.

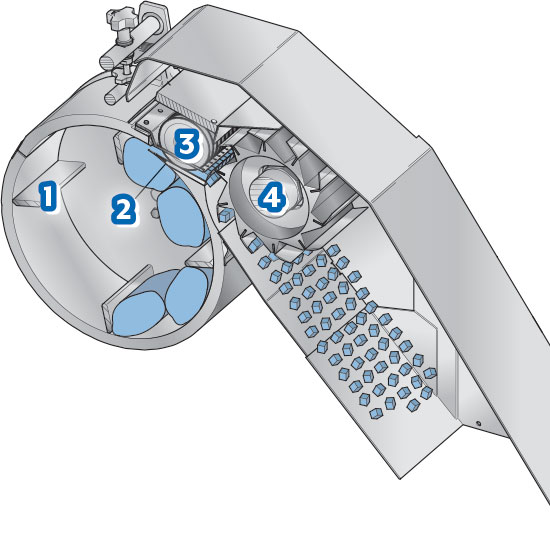

PRECISION CUTS

The Sprint 2® Dicer cutting principle features a compact cutting zone. The close proximity of each cutting station establishes a compact zone to promote the exactness of every cut.

HIGH CAPACITY PRODUCTION

High capacity capabilities and continuous operation for uninterrupted production.

CUT RANGE

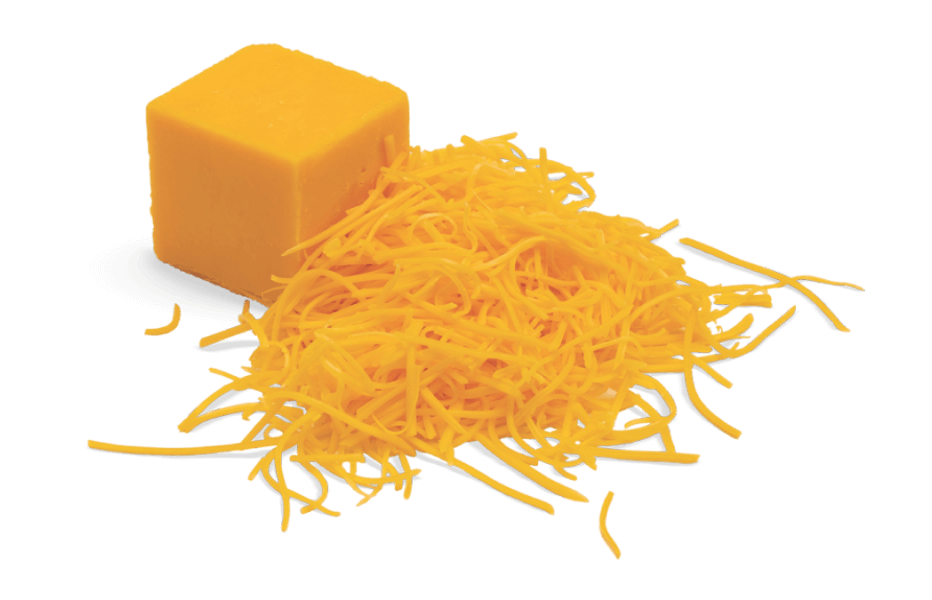

The Sprint 2® Dicer produces dices, strips, slices, granulations, and shreds.

URSCHEL SERVICE & SUPPORT

Urschel cutting machinery is backed by solid service and support. Urschel customer service is just as reliable and dependable as the rugged equipment Urschel manufactures.

Applications

The Sprint 2® Dicer accepts a maximum infeed product of 6.5″ (165 mm) in any dimension. May come equipped with VFD or with soft start in a 3 HP (1.5 kW) motor, or the cost-effective option of a 1.5 HP (1.1 kW) soft start. Features continuous operation for uninterrupted production.

Cutting zones are completely separate from mechanical zones. Rounded tube frame contributes to sanitary design and ease cleaning. Provides slicing-only capability by removing the circular and crosscut knife spindles. Provides 2- or 3-dimensional cutting by adjusting the slice thickness, crosscut, and circular knife spindles for a full range of dices, crumbles/granulations, or strips. A variety of shreds are also available. The crosscut knife spindle in conjunction with the other cutting components create a compact cutting zone establishing precision cuts as product moves throughout the process.

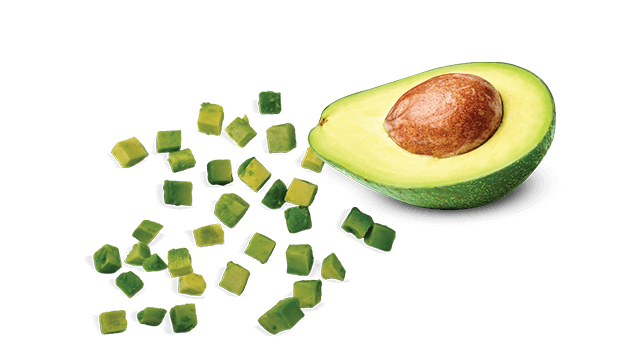

Avocado

1/4″ (6.4 mm) Dice

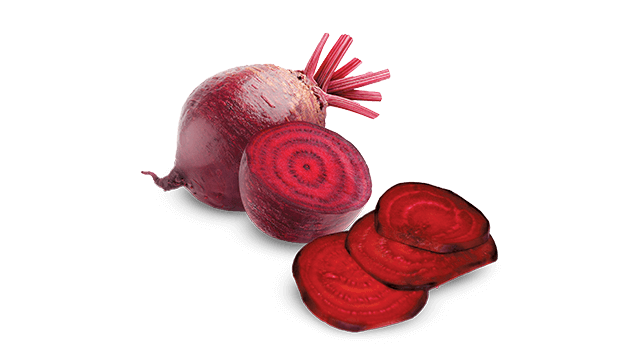

Beet

1/8″ (3.2 mm) Slice

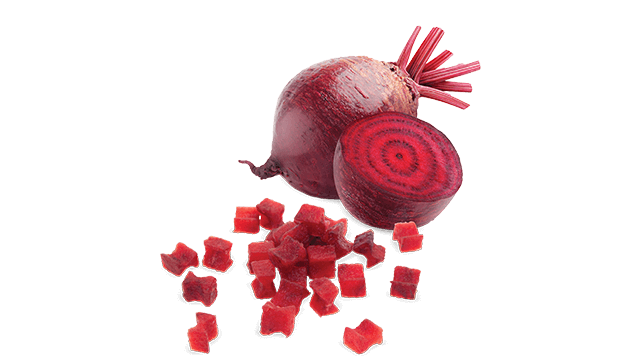

Beet

1/4″ (6.4 mm) Bowtie

Cabbage

3/8″ (9.5 mm) Dice

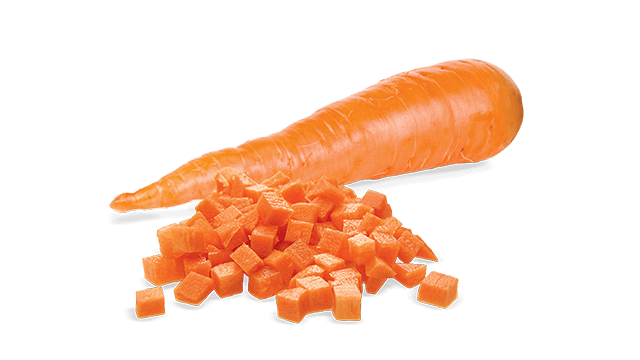

Carrot

1/4″ (6.4 mm) Dice

Cauliflower

Riced Cut

Chocolate Chip Cookie

Large Granulation

Cracker

Small Granulation

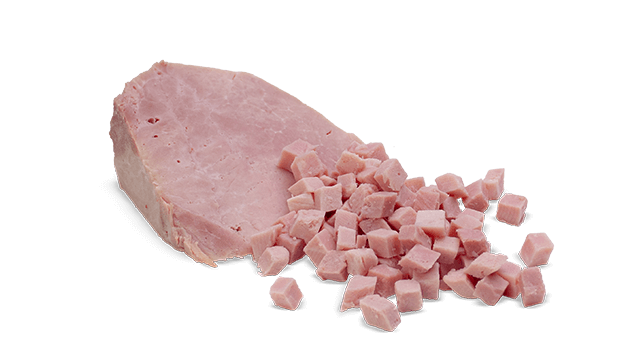

Ham

3/8″ (9.5 mm) Dice

Hard Boiled Egg

7/8 x 5/8 x 7/8″ (22.2 x 15.9 x 22.2 mm) Dice

Kale

1/8″ (3.2 mm) Chop

Lettuce

3/4″ (19.1 mm) Chop

Mango

3/4″ (19.1 mm) Dice

Mushroom

1/8 x 1/8 x 1/4″ (3.2 x 3.2 x 6.4 mm) Dice

Mushroom

1/4″ (6.4 mm) Slice

Olive

1/8″ (3.2 mm) Dice

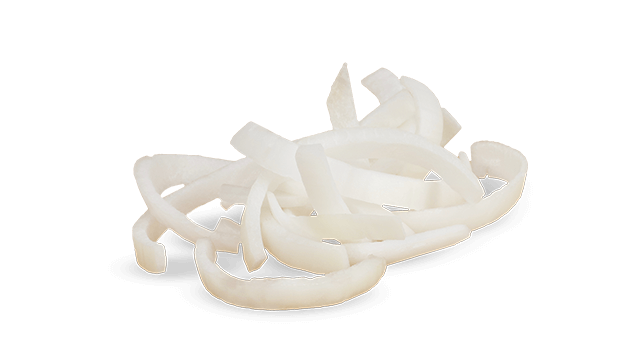

Onion

1/4″ (6.4 mm) Dice

Onion

3/8″ (9.5 mm) Strip

Pepper

3/8″ (9.5 mm) Dice

Pepper

3/8 x 1″ (9.5 x 25.4) Strip

Pepperoni

3/8″ (9.5 mm) Dice

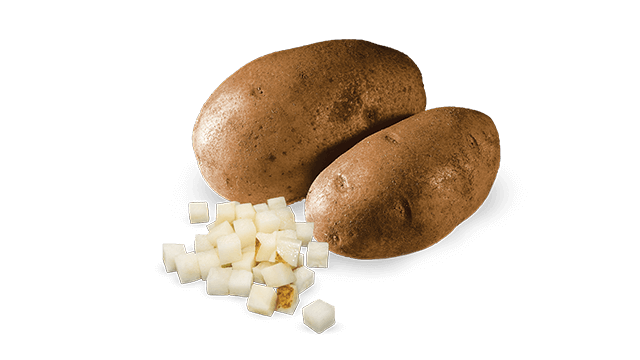

Potato

3/8″ (9.5 mm) Strip

Potato

3/4″ (19.1 mm) Dice

Potato

1/4″ (6.4 mm) Dice

Sandwich Cookie

Small Granulation

Seitan

3/8″ (9.5 mm) Dice

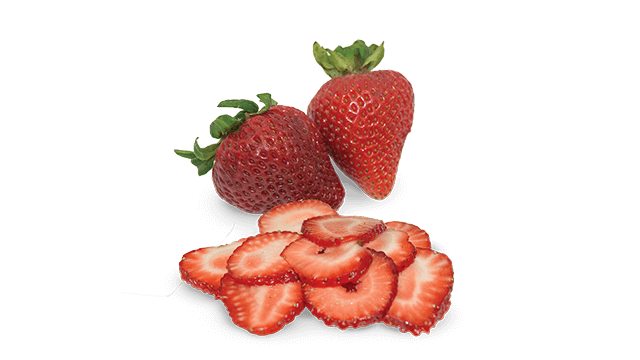

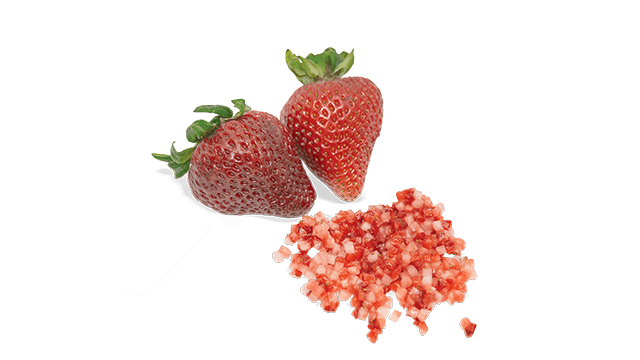

Strawberry

1/4″ (6.4 mm) Slice

Strawberry

1/8″ (3.2 mm) Dice

Tofu

1/2″ (12.8 mm) Dice

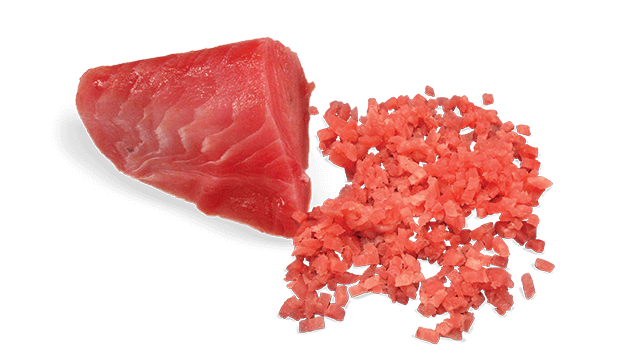

Tuna

1/4″ (6.4 mm) Dice

Tomato

1/2″ (12.8 mm) Dice

Zucchini

Crinkle Vegetable Noodle Cut

Specs

Sprint 2® Dicer

| LENGTH | 70.31″ (1786 mm) |

| WIDTH | 58.30″ (1481 mm) |

| HEIGHT | 60.95″ (1548 mm) |

| NET WEIGHT | 1000 lb (454 kg) |

| MOTOR | 1.5 HP (1.1 kW) soft start, 3 HP (2.2 kW) soft start, or 3 HP (2.2 kW) with VFD |

Sprint 2® Dicer with Discharge Conveyor

| LENGTH | 70.31″ (1786 mm) |

| WIDTH | 61.56″ (1564 mm) |

| HEIGHT | 60.95″ (1548 mm) |

| NET WEIGHT | 1050 lb (476 kg) |

| MOTOR | 3 HP (2.2 kW) soft start, or 3 HP (2.2 kW) with VFD |

Measurements and weights may vary depending on machine configuration.

Operating Principle

Sprint 2® Dicer

- Impeller Paddles

- Slicing Knife

- Circular Knives

- Crosscut Knives

Knife Info

Sprint 2® Slicing Knife

Slice Adjustment Dials and Locks in the Slice Size

Slicing knives are available handled, as an easily replaceable, lower cost option, standard, with or without shaped edge, and special heavy duty. Most slicing knives are specially notched to work directly with dedicated circular knife spindle set-ups. Specially crafted bevels, heavy duty slots, some widely and some narrowly slotted.

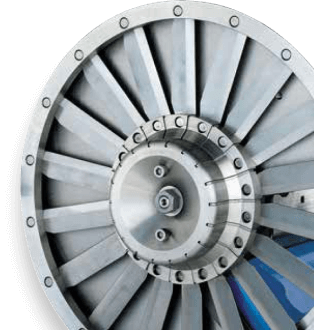

Sprint 2® Dicer Circular Knives

Holding Tolerances of All Parts on the Circular Knife Spindle is Crucial

Tolerances of circular knife spindle parts are maintained at less than one ten-thousandth of an inch. The balance and geometry of the spindle components are also maintained in order to achieve optimal cutting and avoid any part-to-part negative movement or a potential crash.

Sprint 2® Dicer Crosscut Knives

Knives at an Angled Bend in Parallel that Horizontally Cross the Vertical Axis of the Circular Knife Cut

Urschel has developed diverse styles suitable for different products crucial to the cutting process.

Specify Urschel Knives

Urschel Knives are Crafted with Proper Geometry, Balance, and Sharpness to Work with Urschel Cutting Components and Urschel Cutting Machinery

Urschel manufactures millions of knives every year and remains at the forefront of knife technology evolving with the needs of the dynamic food processing industry.

Need Help with Knives for Your Urschel Cutting Machinery?

Contact us today to get help with upgrading or replacing your knives with original Urschel parts.

Types of Cuts

Slice

Flat or crinkle slices: 1/16 to 1″ (1.6 to 25.4 mm)

Dice/Crumble/Strip

2- and 3-dimensional cutting involves adjusting the slice thickness, and adjustment or removal of the circular or crosscut spindles.

Circular Range: 1/8 to 3″ (3.2 to 76.2 mm)

Crosscut Range: 3/32 to 1″ (2.4 to 25.4 mm)

Crosscut Crinkle Range: (.076″ (1.9 mm) depth): 9/32 to 9/16″ (7.1 to 14.3 mm)

Crosscut Deep Crinkle Range: (.125 to .145″ (3.2 to 3.7 mm) depth): 3/8 to 1/2″ (9.5 to 12.7 mm)

Shred

Fine, medium, and coarse shreds can be produced on hot or chilled cooked meat products by using shredding disc spindle in place of the crosscut knife spindle.

Want to Test Cut Your Specific Product?

Contact Urschel to learn more about the product test cutting process.

Frequently Asked Questions

Ask a Question

"*" indicates required fields

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Machine Brochure Sprint 2® Dicer

Download (link opens in new window)

Fact Sheet Sprint 2® Dicer with Conveyor

Download (link opens in new window)

Fact Sheet Sprint 2® Dicer

Download (link opens in new window)

Machine Brochure Sprint 2® Dicer (FR)

Download (link opens in new window)

Fact Sheet Sprint 2® Dicer with Conveyor (FR)

Download (link opens in new window)

Fact Sheet Sprint 2® Dicer (FR)

Download (link opens in new window)

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Machine Brochure Sprint 2® Dicer

Download (link opens in new window)

Fact Sheet Sprint 2® Dicer with Conveyor

Download (link opens in new window)

Fact Sheet Sprint 2® Dicer

Download (link opens in new window)

Machine Brochure Sprint 2® Dicer (FR)

Download (link opens in new window)

Fact Sheet Sprint 2® Dicer with Conveyor (FR)

Download (link opens in new window)

Fact Sheet Sprint 2® Dicer (FR)

Download (link opens in new window)

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.