E TranSlicer® Cutter

Precision Slicing with Maximum Versatility

-

Key Features

-

Applications

-

Specs

-

Knife Info

-

Types of Cuts

-

Media & Brochures

-

FAQs

Key Features

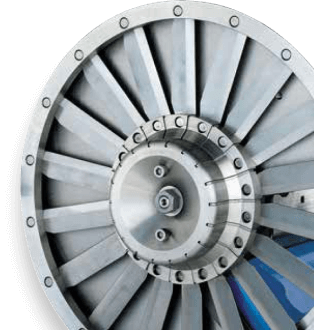

INTERCHANGEABLE CUTTING WHEELS

Interchangeable 20″ (508 mm) diameter stainless steel cutting wheels: slicing, MicroSlice®, julienne, and shredding.

DYNAMIC BRAKING

Dynamic, stainless steel motors are specifically designed for demanding food production environments to withstand rigorous washdowns.

STAINLESS STEEL

Stainless steel materials; machine size designed to fit easily into existing processing lines.

EASE OF SANITATION AND MAINTENANCE

Stainless steel construction with sloped surface areas to deter bacterial growth. Hinged access panels promote sanitation and ease of maintenance.

SIMPLIFIED WHEEL CHANGEOVERS

Cutting wheel mount/holder assembly allows simple wheel changeovers.

SANITARY ZONE DESIGN

Sanitary design with all mechanical components completely separate from the food zone.

FULL ACCESS

Hinged/sliding panels offer full access to key areas and are designed to stand off of the frame to minimize overlapping joints, improve inspection, and decrease cleaning.

HIGH CAPACITY PRODUCTION

High capacity capabilities and continuous operation for uninterrupted production.

SELF-DRAINING

Sloped surfaces throughout the machine including a self-draining frame ease cleaning.

URSCHEL SERVICE & SUPPORT

Urschel cutting machinery is backed by solid service and support. Urschel customer service is just as reliable and dependable as the rugged equipment Urschel manufactures.

Applications

E TranSlicer® Cutter

The E TranSlicer® Cutter (METRS) accepts firm products up to 4″ (101.6 mm) in diameter and leafy-type, compressible products up to 6″ (152.4 mm) in diameter. Optional static hold-down, non-powered top belt, or powered top-belt hold-down assemblies are available to maintain positive feeding assistance.

Interchangeable stainless steel cutting wheels include: slicing wheel, patented MicroSlice® wheel, and julienne wheel. The number, placement, degree of pitch, and type of knives coordinate with the cutting wheel and feed belt speed to determine the size of cut. The unique MicroSlice delivers ultra-thin slices for popular applications such as cassava and taro chips. The machine features continuous operation for uninterrupted production.

E TranSlicer® Bias Cutter

Newly developed parts transform the E TranSlicer® Cutter (METRS) from standard slicing to either 35 or 45 degree bias flat or crinkle slicing. Available when ordering a new machine, or as a retrofit kit for E TranSlicer machines in the field.

Once retrofitted, switching over from straight to bias slicing is accomplished in as little as 10 minutes. Designed for hand-fed, batch processing (running at 30 Hz) equipped with a MicroSlice® or slicing wheel set-up. Product is fed through a top chute that delivers product to the slicing wheel to produce bias slices. Infeed product should not exceed 2.5″ (63.5 mm) in diameter.

Asparagus

1″ (25.4 mm) Slice

Asparagus

1-1/2″ (38.1 mm) Slice

Banana Pepper

.3/16″ (4.8 mm) Crinkle Slice

Beef Stick

3/8″ (9.5 mm) Slice

Pepper

3/8″ (9.5 mm) Ring

Baguette

1/8″ (3.2 mm) Slice

Carrot

3/16″ (4.8 mm) Crinkle Slice

Carrot

3/8″ (9.5 mm) Slice

Cassava

.069″ (1.8 mm) Crinkle Slice

Celery

3/8″ (9.5 mm) Slice

Chicken

1/4″ (6.4 mm) Slice

Cilantro

3/8″ (9.5 mm) Slice

Cucumber

1/8″ (3.2 mm) Slice

Eggplant

1/2″ (12.7 mm) Slice

Green Bean

1″ (25.4 mm) Slice

Green Onion

1/8″ (3.2 mm) Slice

Jalapeno

1/8″ (3.2 mm) Slice

Lemon

1/8″ (3.2 mm) Slice

Mango

3/8″ (9.5 mm) Slice

Onion

1/4″ (6.4 mm) Sliver

Pepperoni

1/8″ (3.2 mm) Crinkle Slice

Pickle

1/8″ (3.2 mm) Crinkle Slice

Pickle

1/8″ (3.2 mm) Flat Slice

Pineapple

1/4″ (6.4 mm) Slice

Plantain

1/8″ (3.2 mm) Slice

Romaine Lettuce

1 x 1-1/2″ (25.4 x 38.1 mm) Square

Sweet Potato

.065 (1.7 mm) Slice

Zucchini

1/2″ (12.7 mm) Half Moon Slice

Zucchini

3/16″ (4.8 mm) Slice

Carrot

3/16″ (4.8 mm)

Celery

1″ (25.4 mm)

Pickle

3/16″ (4.8 mm)

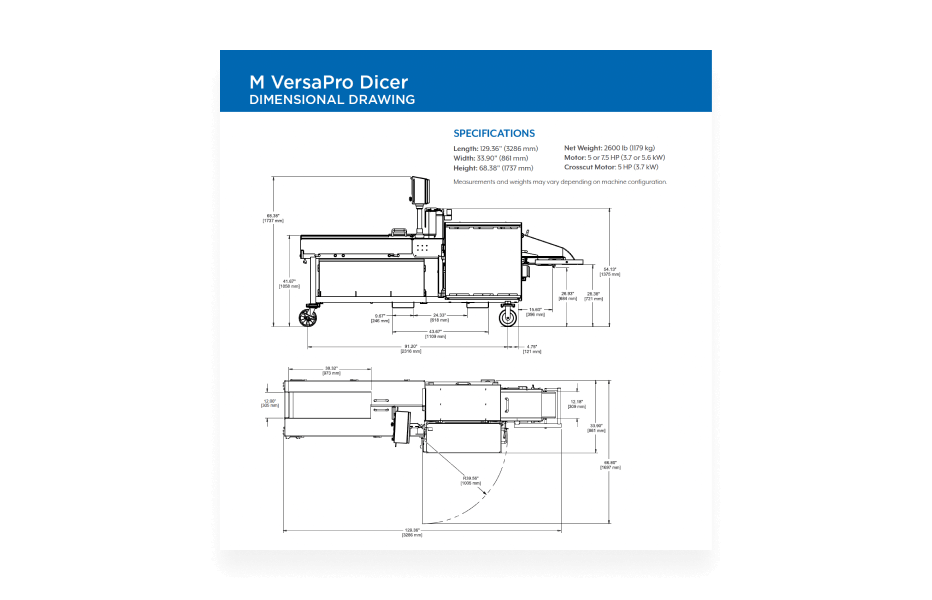

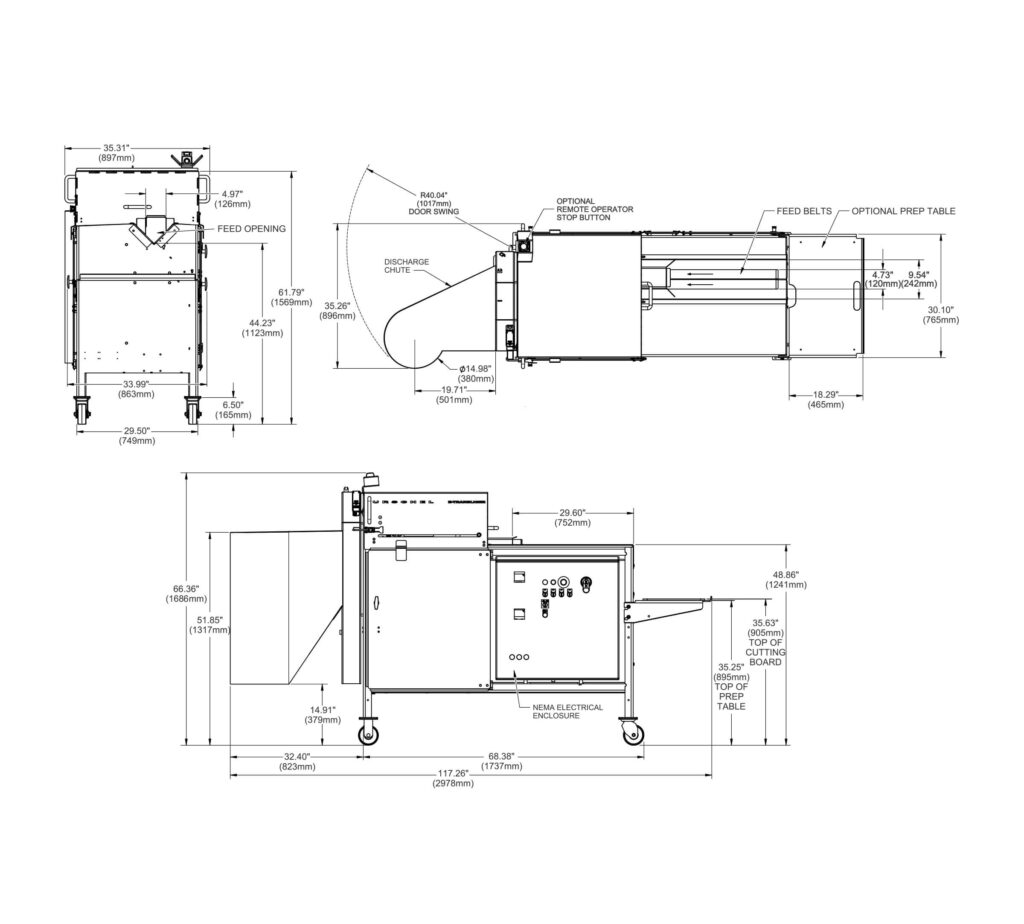

Specs

E TranSlicer® Cutter (METRS)

| LENGTH | 100.78″ (2560 mm) 117.26″ (2978 mm) w/ prep table |

| WIDTH | 35.31″ (897 mm) |

| HEIGHT | 61.79″ (1569 mm) 66.36″ (1686 mm) w/ remote stop |

| NET WEIGHT | 1300 lb (560 kg) |

| CUTTING WHEEL MOTOR | 3 HP (2.2 kW) |

| FEED BELT MOTOR | 1 HP (.75 kW) |

Measurements and weights may vary depending on machine configuration.

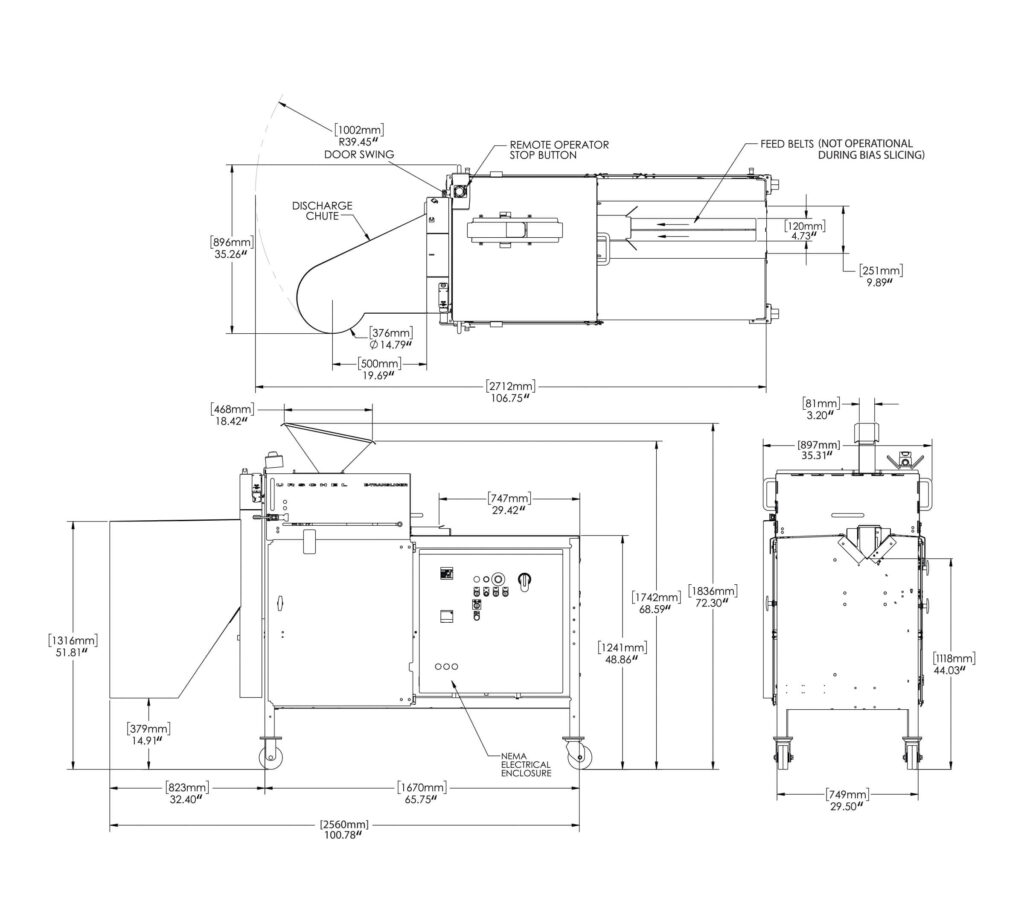

E TranSlicer® Bias Cutter

| LENGTH | 100.78″ (2560 mm) 117.26″ (2978 mm) w/ prep table |

| WIDTH | 35.31″ (897 mm) |

| HEIGHT | 72.30″ (1836 mm) |

| NET WEIGHT | 1300 lb (560 kg) |

| CUTTING WHEEL MOTOR | 3 HP (2.2 kW) |

| FEED BELT MOTOR | 1 HP (.75 kW) |

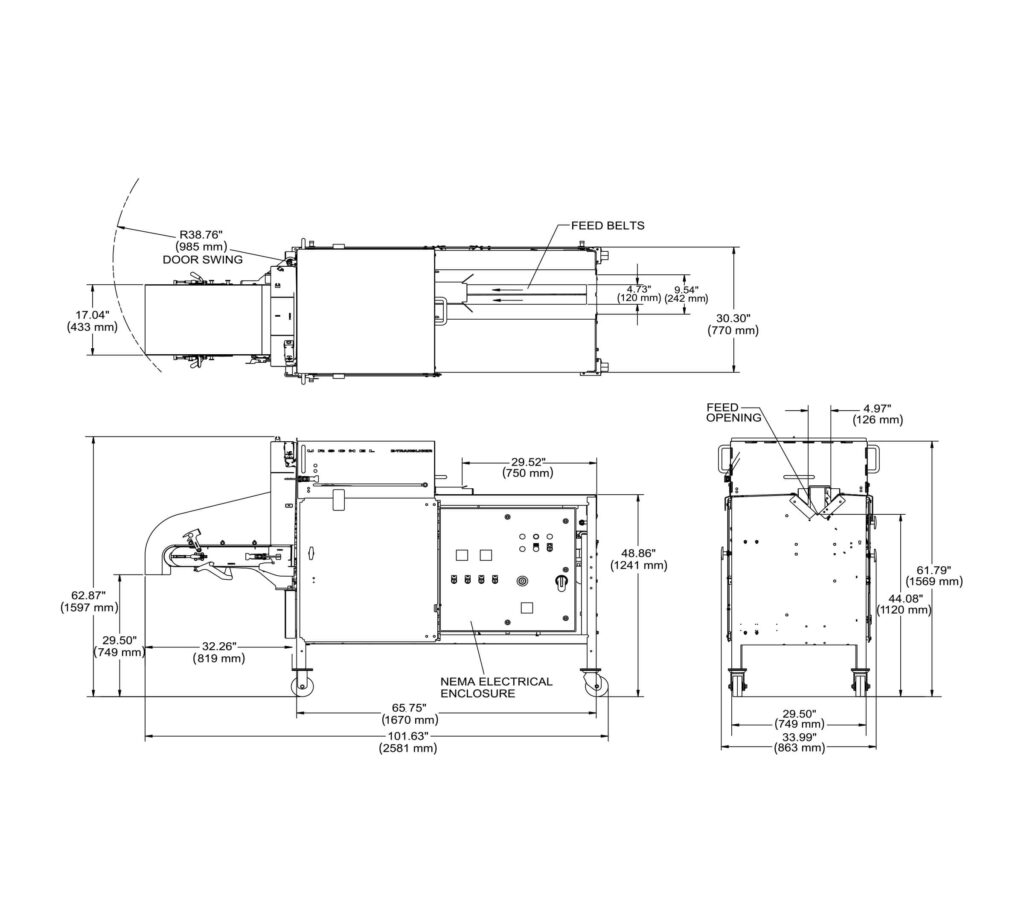

E TranSlicer® Cutter with Discharge Conveyor

| LENGTH | 101.63″ (2581 mm) |

| WIDTH | 33.99″ (863 mm) |

| HEIGHT | 62.87″ (1569 mm) |

| NET WEIGHT | 1540 Ib (700 kg) |

| CUTTING WHEEL MOTOR | 3 HP (2.2 kW) |

| FEED BELT MOTOR | 1 HP (.75 kW) |

| CONVEYOR BELT MOTOR | 1/4 HP (.19 kW) |

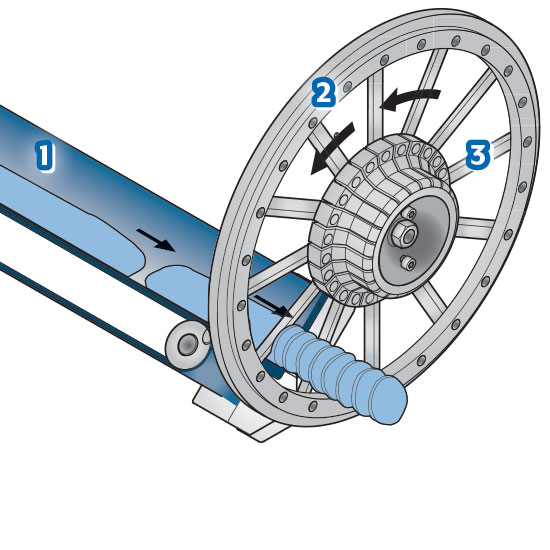

Operating Principle

E Translicer® Cutter

- Feed Belt

- Slicing Wheel

- Slicing Knives

Knife Info

Need Help with Knives for Your Urschel Cutting Machinery?

Contact us today to get help with upgrading or replacing your knives with original Urschel parts.

Types of Cuts

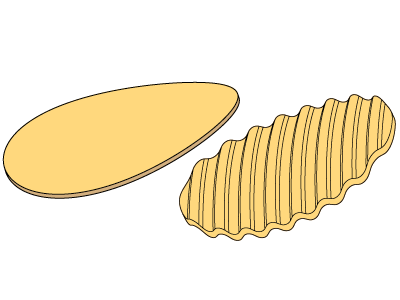

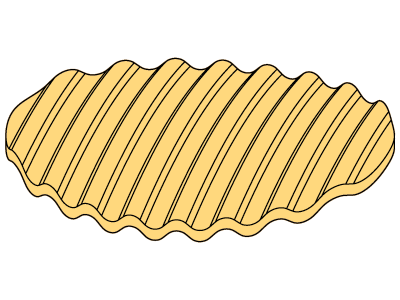

Slicing Wheel

Flat & Crinkle Slice

1/32 to 3″ (.8 to 76.2 mm) Crinkle slices have 4-2/3 waves per inch and with a crinkle depth of 1/16″ (1.6 mm).

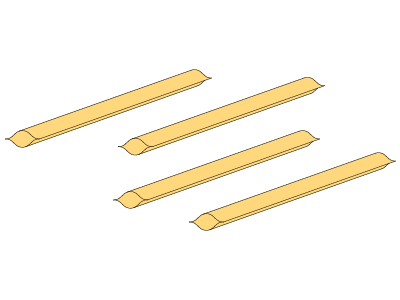

Julienne Wheel

Julienne Cuts

Julienne cuts ranging from 1/2 x 1/2″ (12.7 x 12.7 mm) to 2 x 2″ (50.8 x 50.8 mm).

MicroSlice® Wheel

Flat Slices

.020 to .240″ (.5 to 6 mm).

Crinkle Slices

.069″ (1.8 mm) thickness with 3-1/3 waves per inch and a crinkle depth of .080″ (2.0 mm).

Oval Shred

This shred has an oval-shaped cross section measuring approximately .125″ (3.2 mm) thick by .250″ (6.4 mm) wide.

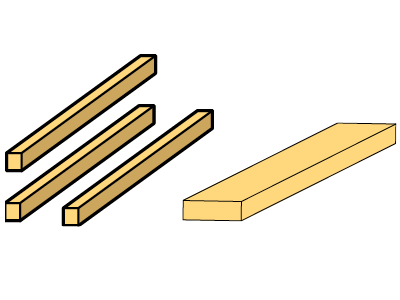

Julienne Strips

A wide range of julienne strips can be made from firm products. Contact your local representative for more information.

Want to Test Cut Your Specific Product?

Contact Urschel to learn more about the product test cutting process.

Media & Brochures

Photography

Videos

Dimensional Drawings

Frequently Asked Questions

Ask a Question

"*" indicates required fields

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Machine Brochure E TranSlicer® Cutter

Download (link opens in new window)

Fact Sheet E TranSlicer® Cutter

Download (link opens in new window)

Fact Sheet E TranSlicer® Cutter with Discharge Conveyor

Download (link opens in new window)

Fact Sheet E TranSlicer® Bias Cutter

Download (link opens in new window)

Machine Brochure E TranSlicer® Cutter (FR)

Download (link opens in new window)

Fact Sheet E TranSlicer® Cutter (FR)

Download (link opens in new window)

Fact Sheet E TransSlicer® Bias Cutter (FR)

Download (link opens in new window)

Fact Sheet E TranSlicer® Cutter (POR)

Download (link opens in new window)

Fact Sheet E TranSlicer® Bias Cutter (POR)

Download (link opens in new window)

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Machine Brochure E TranSlicer® Cutter

Download (link opens in new window)

Fact Sheet E TranSlicer® Cutter

Download (link opens in new window)

Fact Sheet E TranSlicer® Cutter with Discharge Conveyor

Download (link opens in new window)

Fact Sheet E TranSlicer® Bias Cutter

Download (link opens in new window)

Machine Brochure E TranSlicer® Cutter (FR)

Download (link opens in new window)

Fact Sheet E TranSlicer® Cutter (FR)

Download (link opens in new window)

Fact Sheet E TransSlicer® Bias Cutter (FR)

Download (link opens in new window)

Fact Sheet E TranSlicer® Cutter (POR)

Download (link opens in new window)

Fact Sheet E TranSlicer® Bias Cutter (POR)

Download (link opens in new window)

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.