Model CC Slicer

Interchangeable Cutting Heads Offer Flexibility in Shape Cuts

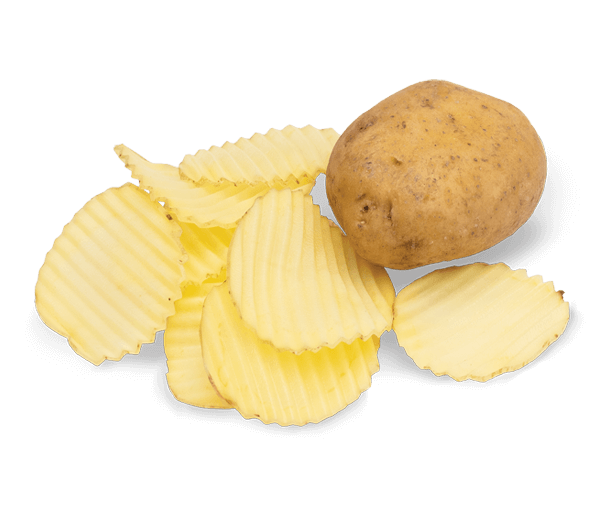

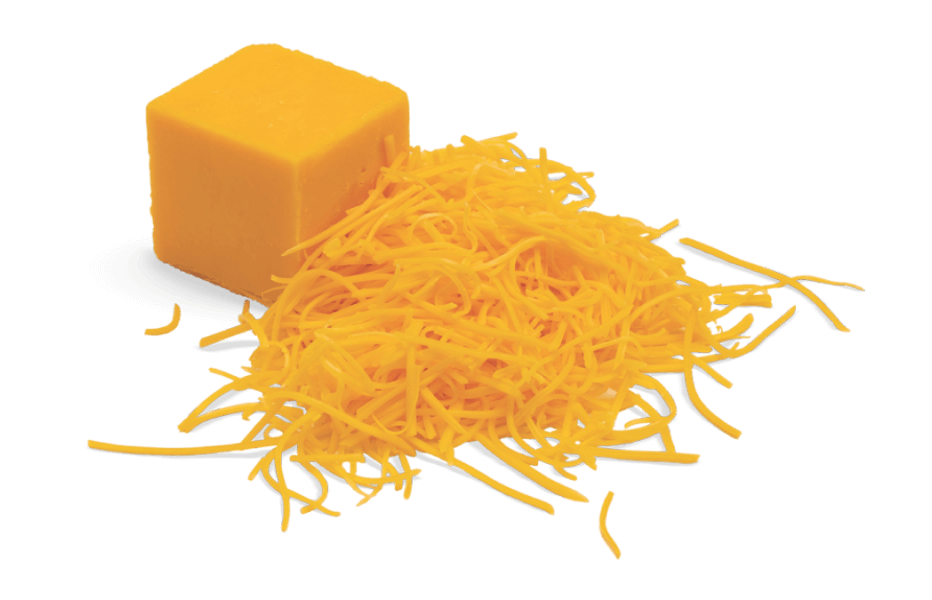

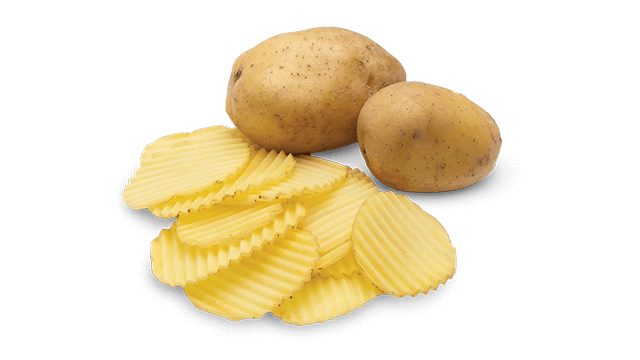

Food processors rely on the Urschel Model CC Slicer to produce precise, uniform slices and shreds at high production capabilities with excellent results including potato slices, fruits, vegetables, and cheese shreds.

-

Key Features

-

Applications

-

Specs

-

Knife Info

-

Types of Cuts

-

Media & Brochures

-

FAQs

Key Features

IDEAL FOR A WIDE RANGE OF PRODUCTS

With a range of different cuts, this potato chip slicer is also ideal for various other food products, such as cheese, vegetables, and nuts.

SANITARY ZONE DESIGN

Sanitary design with all mechanical components completely separate from the food zone.

CUT TYPES

Offers many different types of cuts including flat slices, “V” slices, Flat-V® shreds, Flat-V® slices, crinkle cut potato slices, strip cuts, full shreds, “V” shreds, oval shreds, wide oval shreds, crescent shreds, wide crescent shreds, and grating options.

HIGH CAPACITY PRODUCTION

High capacity capabilities and continuous operation for uninterrupted production.

MICROADJUSTABLE® SLICING

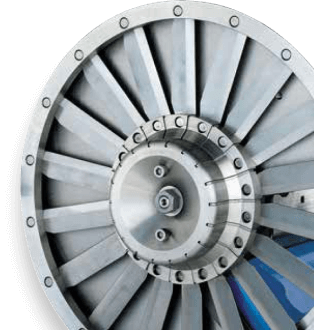

MicroAdjustable® Slicing Head (SL-14) features 14 cutting stations that maximize slice engagement. Increased cutting stations deliver higher capacities versus the fully-adjustable 8-station cutting head.

URSCHEL SERVICE & SUPPORT

Urschel cutting machinery is backed by solid service and support. Urschel customer service is just as reliable and dependable as the rugged equipment Urschel manufactures.

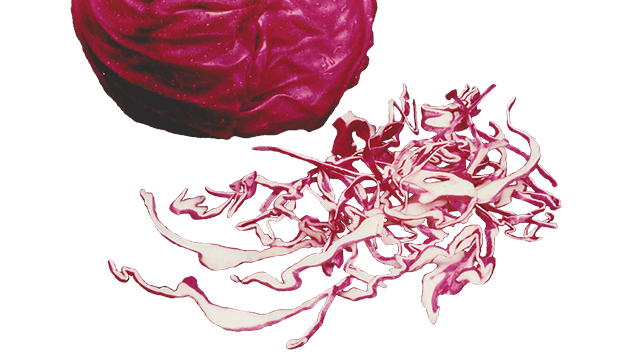

Applications

Food processors rely on the Urschel Model CC (MCC) to produce precise, uniform slices, strips cuts, shreds, and granulations at high production capabilities with excellent results. Products processed on the Model CC include potatoes for chips, shredded cheese, mushrooms, cabbage, lettuce, other vegetables/fruits, nut reductions for bakery ingredients, and pet food ingredients. The Model CC features continuous operation for uninterrupted production and is designed for easy cleanup and maintenance. The Model CC will accept products measuring up to 4″ (101.6 mm) in any dimension.

MicroAdjustable® Slicing Head increases capacity with 14 cutting stations and offers tool-free knife changeovers to greatly reduce time and effort during switching over of heads. Contact Urschel to learn more.

Almond

Sliver

Almond

.080″ (2.0 mm) Flat & V Slice

Broccoli Stem

.125″ (3.2 mm) V-Shred

Carrot

1/8 x 4″ (3.2 x 101.6 mm) Strip

Carrot

1/8″ (3.2 mm) Shred

Carrot

1/4 x 3″ (6.4 x 76.2 mm) Stick

Cheddar Cheese

.070″ (1.8 mm) Full Shred

Processed Cheese

Grating Screen

Cheddar Cheese

Oval Shred

Cheese

Fine Shred

Coconut

Grating Screen

Coconut

.070″ (1.8 mm) Shred

Coconut

.060″ (1.5 mm) Slice

Fresh Mushroom

3/16″ (4.8 mm) Slice

Grated Peanut

Grating Screen, 1/8″ (3.2 mm) Granulation

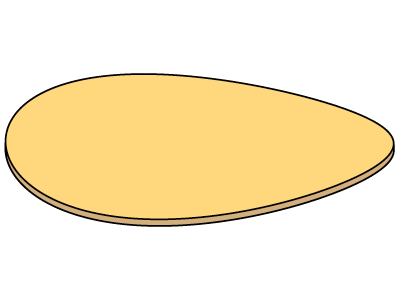

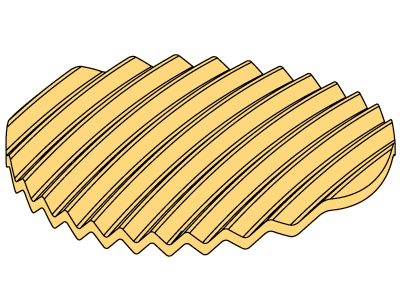

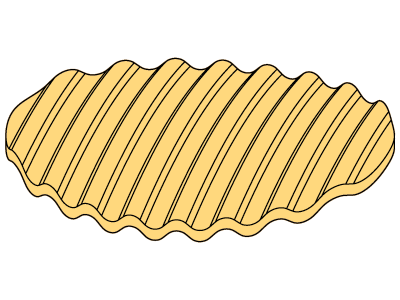

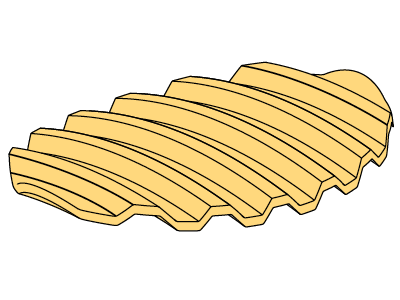

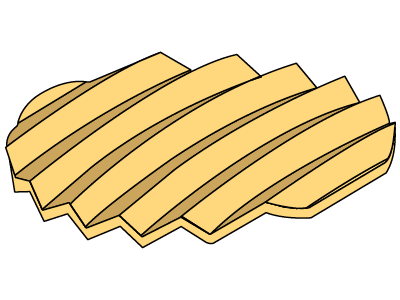

Potato

.080″ (2.0 mm) thick V Slice

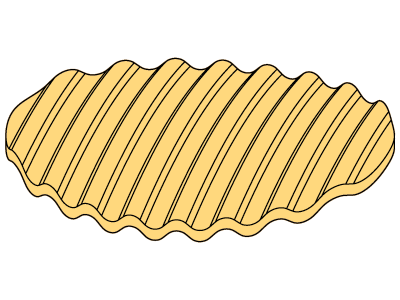

Potato

Flat-V® Slice

Potato

Flat Slice

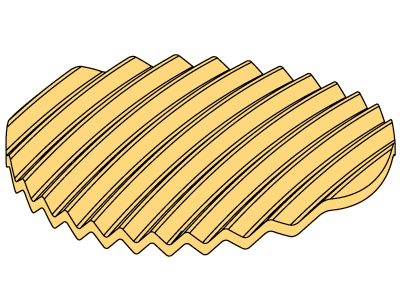

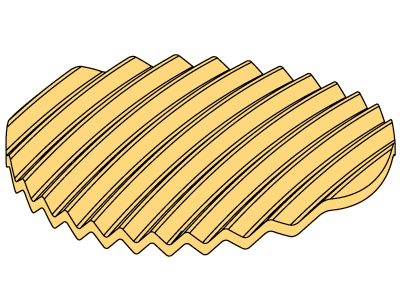

Potato

Crinkle Slice

Potato

.212″ V Shred

Potato

Flat-V® Shred

Potato

V Slice

Potato

.060″ (1.5 mm) V Slice

Pretzel

Granulation

Red Cabbage

.090″ (2.3 mm) Flat Slice

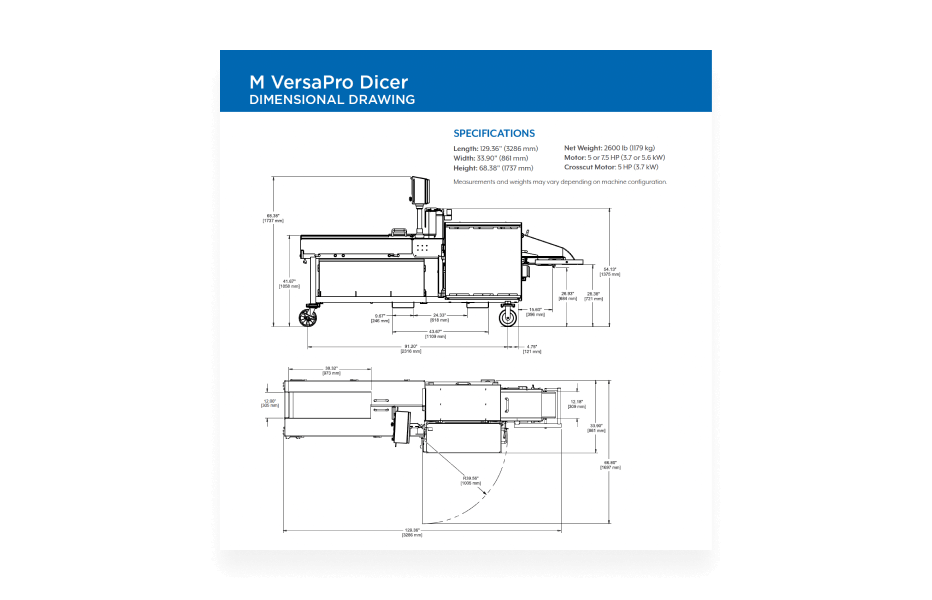

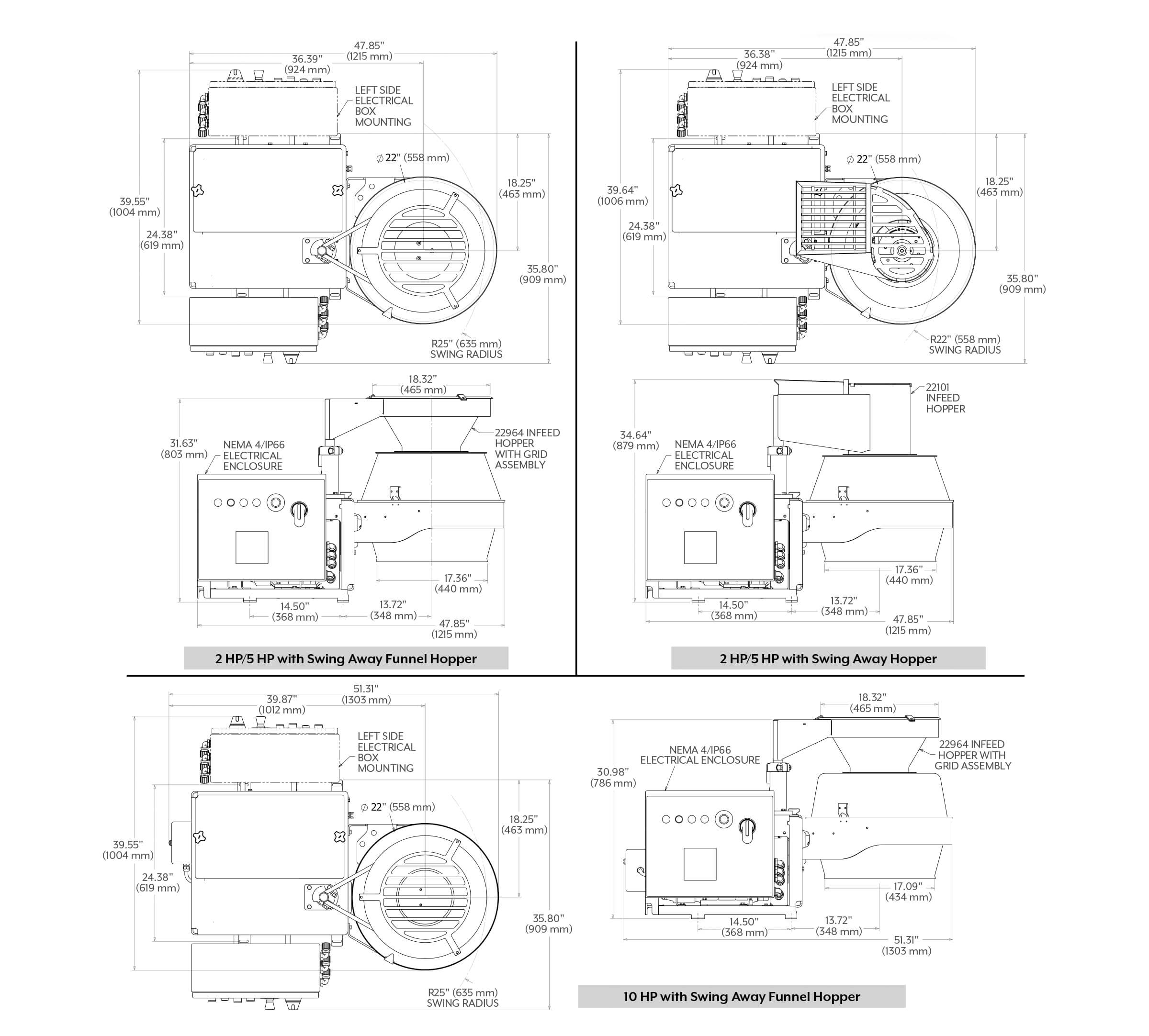

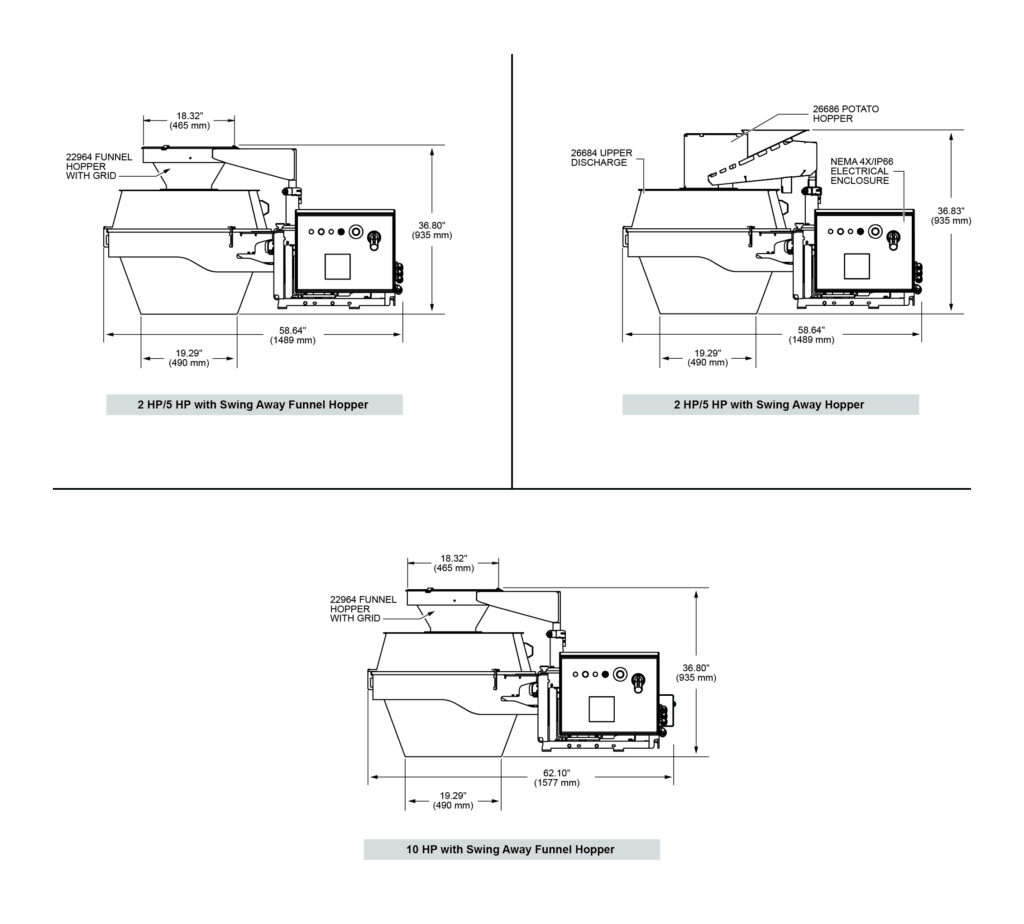

Specs

22″ (559 mm) Cutting Enclosure

| LENGTH: 2 or 5 HP | 47.85″ (1215 mm) |

| LENGTH: 10 HP | 51.31″ (1303 mm) |

| WIDTH: | 35.80″ (909 mm) |

| HEIGHT: 2 or 5 HP | 34.64″ (799 mm) |

| NET WEIGHT: 2 or 5 HP | 550 lb (250 kg) |

| NET WEIGHT: 10 HP | 680 lb (310 kg) |

| MOTOR | 2, 5, or 10 HP (1.5, 3.7, or 7.5 kW) |

32″ (813 mm) Cutting Enclosure

| LENGTH: 2 or 5 HP | 58.64″ (1489 mm) |

| LENGTH: 10 HP | 62.10″ (1577 mm) |

| WIDTH: | 35.73″ (908 mm) |

| HEIGHT: | 36.83″ (935 mm) |

| NET WEIGHT: 10 HP | 700 lb (318 kg) |

| MOTOR | 2, 5, or 10 HP (1.5, 3.7, or 7.5 kW) |

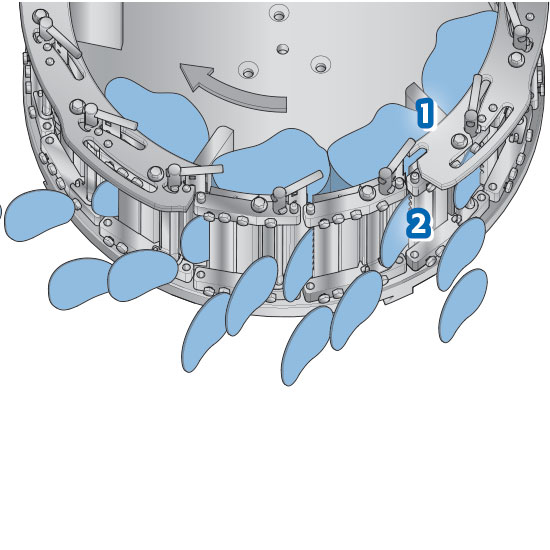

Operating Principle

Model CC Slicer

- Impeller Paddle

- Slicing Knife

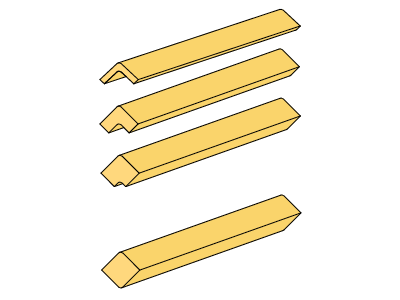

Knife Info

Need Help with Knives for Your Urschel Cutting Machinery?

Contact us today to get help with upgrading or replacing your knives with original Urschel parts.

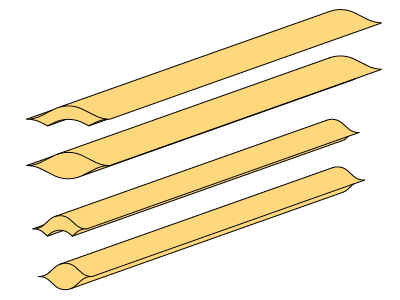

Types of Cuts

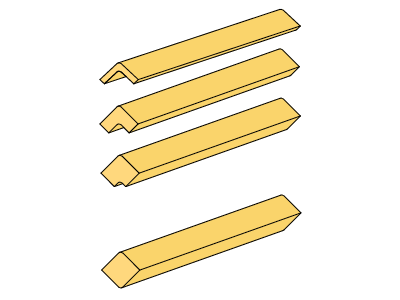

14-Station MicroAdjustable® SL-14 Head

Flat Slice

6 heads available ranging in thickness from .030 – .203″ (.760 – 5.16 mm): Optimal .040 – .060″ (1.02 – 1.52 mm) or Extended .030 – .063″ (.76 – 1.60 mm); Optimal .060 – .080″ (1.52 – 2.03 mm) or Extended .050 – .083″ (1.3 – 2.11 mm); Optimal .090 – .110″ (2.29 – 2.79 mm) or Extended .080 – .113″ (2.03 – 2.87 mm); Optimal .120 – .140″ (3.05 – 3.56 mm) or Extended .110 – .143″ (2.79 – 3.63 mm); Optimal .150 – .170″ (3.81 – 4.32 mm) or Extended .140 – .173″ (3.56 – 4.39 mm); Optimal .180 – .200″ (4.57 – 5.08 mm) or Extended .170 – .203″ (4.32 – 5.16 mm)

.125 V Slice in SlideLocc® or Quick Clamp

.125″ (3.2 mm) V Slice has 8 complete “v’s” to the inch. Depth of “v”is .050″ (1.3 mm).

Slice thickness ranges from .045 – .100″ (1.0 – 2.5 mm); Centers: .125″ (3.2 mm)

Optimal .055 – .075″ (1.40 – 1.91 mm) or Extended .045 – .078″ (1.14 – 1.98 mm)

.212 V Slice in SlideLocc

.212″ (5.4 mm) V Slice has 4.7 “v’s” to the inch. Depth of “v” is .084″ (2.1 mm).

Slice thickness ranges from .040 – .100″ (1.0 – 2.5 mm); Centers: .212″ (5.4 mm).

Optimal .055 – .075″ (1.40 – 1.91 mm) or Extended .045 – .078″ (1.14 – 1.98 mm)

Crinkle Slice in SlideLocc or Quick Clamp

3-1/3 waves to the inch; depth of crinkle is .080″ (2.0 mm). Slice thickness from .040 – .285″ (1.0 – 7.2 mm); Centers: .300″ (7.62 mm).

Optimal .050 – .070″ (1.27 – 1.91 mm) or Extended .040 – .073″ (1.02 – 1.85 mm);

Optimal .070 – .090″ (1.78 – 2.27 mm) or Extended .060 – .093″ (1.52 – 2.36 mm)

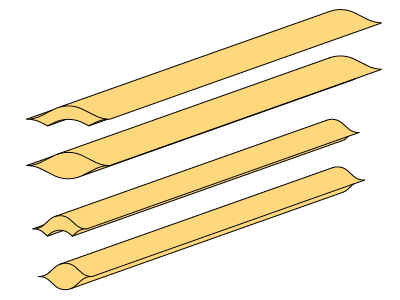

Full & Reduced V Shreds

Full Shred: Diamond-shaped cross section available in three thicknesses: .070, .097, or 125″ (1.8, 2.5, or 3.2 mm).

Reduced V Shred: “V”-shaped cross section.

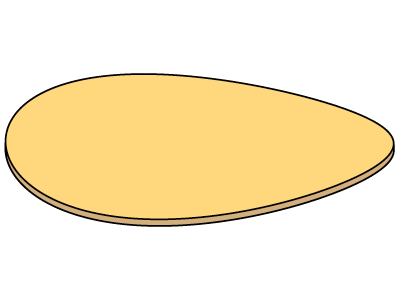

Oval & Reduced Oval (Crescent) Shreds

.300 Oval Shred: Oval-shaped cross section approximately .125″ (3.2 mm) thick by .300″ (7.6 mm) wide.

Crescent Shred: Crescent-shaped cross section.

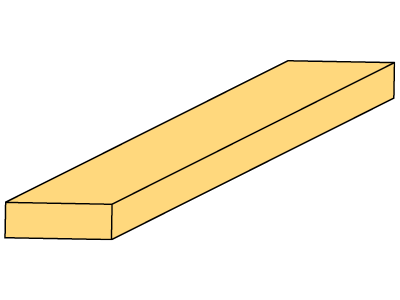

Strip Cut

Rectangular cross section. Width: 3/32, 1/8, 3/16, 1/4, 3/8, 1/2, 9/16, or 3/4″ (2.4, 3.2, 4.8, 6.4, 9.5, 12.7, 14.3, or 19.1 mm)

8-Station, Fully Adjustable Head

Flat Slice

Slice thickness up to .500″ (12.7 mm).

V Slice

Slice thickness up to .500″ (12.7 mm),

.125″ Slice: 8 “V’s” per inch. “V” depth of .050″ (1.3 mm); Centers: .125″ (3.2 mm),

.212″ Slice: 4.7 “V’s” per inch. “V” depth of .084″ (2.1 mm); Centers: .212″ (5.4 mm).

Crinkle Slice

Slice thickness up to .500″ (12.7 mm) with 3-1/2 waves per inch,

.175″ Slice: Crinkle Depth .084″ (2.1 mm), Centers .175″ (4.4 mm),

.300″ Slice: Crinkle Depth .080″ (2.0 mm), Centers .300″ (7.6 mm),

.480″ Slice: Crinkle Depth .076″ (1.9 mm), Centers .480″ (12.2 mm).

Flat-V® Slice

Slice thickness up to .180″ (4.6 mm) with 2.1 corrugations per inch. Corrugation depth of .125″ (3.2 mm); Centers: .473″ (12 mm).

*Z-Cut Slice

Slice thickness up to .325″ (8.3 mm) with 2.1 corrugations per inch. Corrugation depth of .135″ (3.4 mm); Centers: .394″ (10 mm).

*Z-Cut is only available in non-European countries.

Full & Reduced V Shreds

Full Shred: Diamond-shaped cross section available in four thicknesses: .070, .097, .125, or *.285″ (1.8, 2.5, 3.2, or *7.2 mm),

Reduced V Shred: “V”-shaped cross section.

*Limited availability based on customer application. Contact your local Urschel office to verify salability.

Oval & Reduced Oval (Crescent) Shreds

.250″ Oval Shred: Oval-shaped cross section approximately .125″ (3.2 mm) thick by .250″ (6.4 mm) wide,

.480″ Wide Oval Shred: .152″ (3.7 mm) thick by .480″ (12.2 mm) wide,

Crescent Shred: Crescent shaped cross section, Wide Crescent Shred: Wide crescent-shaped cross section.

Strip Cut

Rectangular cross section, Width: 3/32, 1/8, 3/16, 1/4, 3/8, 1/2, 9/16, or 3/4″ (2.4, 3.2, 4.8, 6.4, 9.5, 12.7, 14.3, or 19.1 mm)

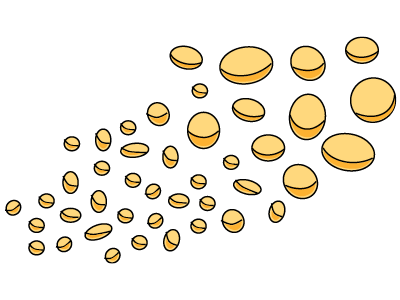

Grating Head

Grating Options

Grating heads offer cuts such as powdered parmesan, coarse granules, and shreds.

Want to Test Cut Your Specific Product?

Contact Urschel to learn more about the product test cutting process.

Media & Brochures

Photography

Videos

Dimensional Drawings

Frequently Asked Questions

Ask a Question

"*" indicates required fields

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Fact Sheet Model CC

Download (link opens in new window)

Model CC Potato Brochure

Download (link opens in new window)

Model CC Non-Potato Brochure

Download (link opens in new window)

Fact Sheet Model CC (FR)

Download (link opens in new window)

Model CC Potato Brochure (FR)

Download (link opens in new window)

Model CC Non-Potato Brochure (FR)

Download (link opens in new window)

Fact Sheet Model CC (POR)

Download (link opens in new window)

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Fact Sheet Model CC

Download (link opens in new window)

Model CC Potato Brochure

Download (link opens in new window)

Model CC Non-Potato Brochure

Download (link opens in new window)

Fact Sheet Model CC (FR)

Download (link opens in new window)

Model CC Potato Brochure (FR)

Download (link opens in new window)

Model CC Non-Potato Brochure (FR)

Download (link opens in new window)

Fact Sheet Model CC (POR)

Download (link opens in new window)

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.