Urschel’s Expertise in Potato Processing

Urschel is the industry-leading manufacturer of industrial potato cutting equipment. We provide the highest quality industrial potato slicers to provide specific cut shapes and sizes, ensuring you find exactly what you need. With over 100 years of experience in food processing, we are committed to innovation and precision in potato processing.

Explore our catalog of potato cutting machines known for their versatility and reliability. Our offerings include the Urschel Model CC Slicer for uniform slicing and equipment capable of producing flat or crinkle dices, such as the DiversaCut 2110A®, Sprint 2®, and DiversaCut Sprint® Dicer, and much more.

Types of Potato Cuts Supported by Urschel Machines

Urschel offers advanced equipment to meet all your potato processing needs, including slicing, French fry cutting, dicing, shredding, and producing potato flakes. Our machines are designed for efficiency and consistency, ensuring optimal texture and flavor in every batch.

Potato Slicing

One of our standout potato slicing models is the Urschel Model CC Slicer, designed to achieve uniform slices. This slicer can produce a variety of cuts, including thin potato chips, thick-cut chips, flat cuts, v-cuts, crinkle cuts, and more (refer to the CC types of cuts section for specifics).

The CCLL (Chip Cut Large Lattice) Slicer also specializes in creating unique corrugated lattices with either thin, coarse, or thick, deep patterns, making it ideal for thin lattice chips or thick waffle fries.

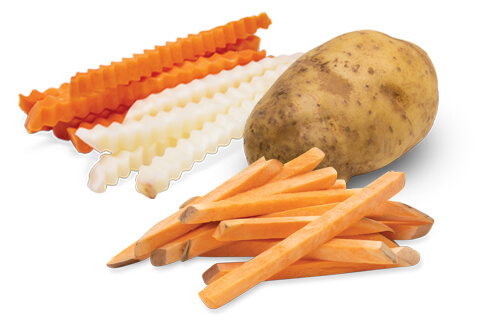

French Fry Straight Flat or Crinkle Strip Cuts

We provide potato cutting machines, such as the DiversaCut 2110A®, Sprint 2®, and DiversaCut Sprint® Dicer, for making flat and crinkle-cut French fries. These machines can produce straight flat strips and various specialty crinkle-cut options.

Potato Specialty Cutting or Dicing

For potato cutting and dicing machines, there is the DiversaCut® line of dicers, which includes the DiversaCut 2110A®, Sprint 2®, and DiversaCut Sprint® dicers. These industrial potato processing machines offer various cutting options, including novelty bow-tie cuts, small to large cubes and dices, and crinkle and flat cuts.

Potato Shreds and Flakes

The Urschel Model CC Shredder features a MicroAdjustable® SH-14 Shred Head and Comitrol® Processor models for fine shreds and flake cuts. Its applications include hash browns, tater tots, value-added flake cuts, potato frites, and shredded potato blends.

Potato Segments and Waterknife Heads

We offer high-quality potato slab and segment cutting machinery, including the Urschel Model VSC Segment Cutter, which can be an alternative to a complete waterjet system. Additionally, the Flo-Cut Model 360 Watergun Cutting and Velocicut® Cutting Heads can be used in waterjet systems or in conjunction with the Urschel Model VSC Segment Cutter. The VSC and cutting heads suit various applications, including wedge cuts, steak fries, segments, slab cuts, and rectangular strips.

Key Features of Urschel Potato Cutting Machines

Some key features of Urschel’s potato cutting machines include limited labor requirements, making them easy to operate and maintain. These machines are designed for precise and consistent outcomes and are built to withstand harsh production environments.

With a high capacity, they are suitable for industrial-scale processing and are engineered for easy cleaning and maintenance to meet hygiene standards. Additionally, our machines offer versatility in cutting various types of potatoes into different shapes.

Why Choose Urschel for Potato Processing?

When you choose Urschel for your potato processing needs, you decide to work with a leader in the food processing industry. Our advanced, patented technology reduces waste and provides processing solutions. Our friendly customer support team and training resources are always ready to help. Enjoy our complimentary sample test cutting of your product to meet your specific, precise cutting production line goals. With our worldwide sales and support network, you can count on us to be there whenever you need assistance.

Applications of Urschel Machines in Potato Processing?

The various applications of Urschel Machines in potato processing include:

- Frozen, Store-Bought Potato Products: This includes French fries, wedges, hash browns, tater tots, cubes, dice, and potatoes O’Brien with peppers and onions.

- Restaurant and Chain Store Potato Supplier Products include prepared French fries, deep crinkle fries, and waffle lattice fries.

- Snack Food Processing: This is for chippers and includes baked or fried flat slices, crinkle slices, or V-shaped slices, all packaged for retail.

- Fresh Potato Products for Schools and Commissaries: This involves slicing, shredding, or dicing potatoes for various uses such as chips, shreds for salads, cooking, or baking, as well as the production of French fries.

- Ready-To-Cook Products in Grocery Store Refrigerated Sections: This includes diced or shredded potatoes, which are available for quick meal preparation.

What Makes Urschel Stand Out from the Competition?

The Urschel CC (Chip Cutter) potato slicer is the top choice in the snack food industry and is preferred by leading potato chip processors. Known for its durability, Urschel’s precision cutting machinery meets the high food production demands.

Many Urschel machines remain operational for 30 to 50 years, with all necessary parts, including knives and cutting assemblies, manufactured in-house to ensure compatibility with the originals.

Urschel also offers a global support network for food processors and provides complimentary test-cutting services to demonstrate the quality and precision of its equipment.

Client Success Stories & Testimonials

Discover why Urschel customers value their experience with our innovative industrial potato processing equipment. Customers appreciate the durability of our machinery and view us as a partner in productivity, whether they are finding or creating the ideal Urschel machine to meet their processing needs. Leading food processors agree that Urschel is a long-term partner in productivity.

From initial installation and start-up to training, instruction manuals, videos, and ongoing service, Urschel offers comprehensive customer support. We maintain a stock of high-volume parts that are frequently ordered to ensure on-demand shipment, reducing costly downtime.

FAQs About Urschel Potato Processing Machines

What types of potato cuts can Urschel machines handle?

The Urschel Model CC Slicer will produce flat, v, crinkle, and z-cut slices for potato chips and shreds, depending on the cutting head configuration. Urschel also carries the DiversaCut® Line, which delivers dices, strips for French fries, and shreds—the same machine can be set up to cut each of these, depending on the cutting parts. In addition, the Comitrol® Series will produce flake cuts for value-added products to create hashbrowns and similar potato products.

How do Urschel machines ensure consistent results?

Urschel engineers each part and operating principle to perform optimally. Metals and manufacturing methods are key to every Urschel cutting machine’s proper design and function. Urschel also understands food product characteristics and designs cutting methods for specific food products, including knives.

Are Urschel machines easy to operate and maintain?

Urschel cutting machines are simple to operate at the push of a button and can also be automatically run via PLC-controlled systems. Complete instruction manuals accompany each machine and outline routine operation and maintenance procedures. Service technicians are also available to provide customer support. Often, specially made gauges or tools are available, manufactured by Urschel, so customers can changeover parts or adjust in a matter of minutes.

Contact Urschel Today for Custom Potato Slicing Solutions

Reach out to us to learn how we can meet your unique processing needs or to schedule a free-of-charge test cut of your product. For more information, contact your nearest Urschel office, where our knowledgeable team is ready to assist you.

If you’re interested in specific machines or want to explore our innovative offerings, please take a moment to browse our comprehensive catalog, which is available here.