TranSlicer® 2520 Cutter

Precision, High Capacity Slicing Meets Next Level Sanitation

In the TranSlicer® Series, rely on the TranSlicer® 2520 Cutter to provide optimal, high capacity cutting of commercial food processing applications with cost-savings related to reduced cleaning and inspection times.

-

Key Features

-

Applications

-

Specs

-

Knife Info

-

Types of Cuts

-

Media & Brochures

-

FAQs

Key Features

FRESH CUT SOLUTIONS

Industrial commercial food processing of fresh-cut salads, leafy vegetables, celery, leek, carrots, cucumbers, and fruits.

FEED BELT CONFIGURATIONS

To accommodate different types of products, the machine offers a choice between three feed belt configurations: primary and secondary belts, full-length primary belts, or the more compact machine version featuring shorter primary belts.

NEXT LEVEL SANITATION

The design concept encompasses the next generation of sanitation to greatly reduce cleaning times. HMI option is available.

EASE OF SANITATION AND MAINTENANCE

Stainless steel construction with sloped surface areas to deter bacterial growth. Hinged access panels promote sanitation and ease of maintenance.

EXPEDITED WASHDOWNS

Customers, on average, are saving 25 minutes per washdown/cleaning versus previously owned machines.

SANITARY ZONE DESIGN

Sanitary design with all mechanical components completely separate from the food zone.

SELF DRAINING DESIGN

Self-draining, angled channel frame eliminates flat surfaces to deter bacterial build-up and ease washdowns.

HIGH CAPACITY PRODUCTION

High capacity capabilities and continuous operation for uninterrupted production.

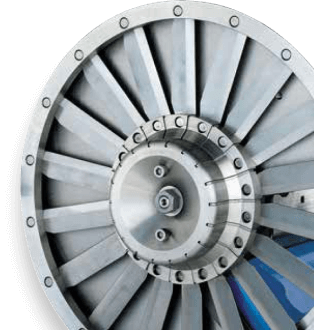

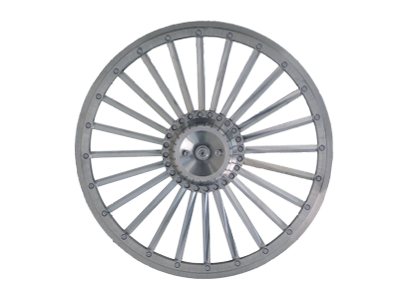

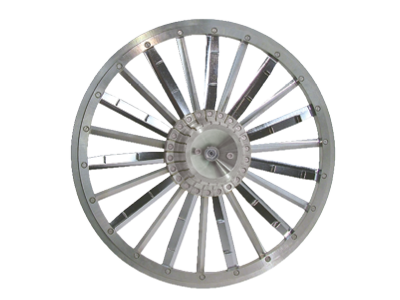

INTERCHANGEABLE CUTTING WHEELS

25″ (635 mm) diameter interchangeable stainless steel cutting wheels.

URSCHEL SERVICE & SUPPORT

Urschel cutting machinery is backed by solid service and support. Urschel customer service is just as reliable and dependable as the rugged equipment Urschel manufactures.

Applications

Building on the original TranSlicer that revolutionized the commercial, fresh-cut salad industry, Urschel introduces the new TranSlicer 2520 Cutter. The TranSlicer 2520 processes a variety of products for the commercial food processing industry such as leafy vegetables, celery, leek, carrots, cucumbers, and fruits.

The TranSlicer 2520 implements many of the features of the TranSlicer 2510 Cutter: 25″ (635 mm) diameter interchangeable stainless steel cutting wheels; sanitary, stainless steel design; types of cut; accepts infeed of compressible food products up to 8″ (203 mm) in diameter, or firm products up to 6-3/4″ (171 mm) in diameter; and operates continuously to achieve high capacities with uninterrupted production. The number, placement, degree of pitch, and type of knives coordinate with the cutting wheel and feed belt speed to determine the size of the cut.

To accommodate different types of products, the machine offers a choice between three feed belt configurations: primary and secondary belts, full length primary belts, or the more compact machine version featuring shorter primary belts. The machine operates via a variable frequency drive (VFD). The feed zone is completely separate from the mechanical zone to promote sanitation.

The overall design of the 2520 sets itself apart. The concept encompasses the next generation of sanitation to greatly reduce cleaning times. Accessibility to every area of the machine expedites washdowns. All surfaces are engineered to promote water drainage. Stand-offs located throughout minimize overlapping joints and improve inspection and decrease cleaning times. IP69K rated IEC (International Electrotechnical Commission) electrical components incorporated throughout the machine withstand high-pressure, high-temperature washdowns. Rely on the TranSlicer 2520 to provide optimal, high capacity cutting with cost-savings related to reduced cleaning and inspection times.

Romaine Lettuce

1 x 1-1/2″ (25.4 x 38.1 mm) Square

Cucumber

1/8″ (3.2 mm) Slice

Leek

1/8″ (3.2 mm) Slice

Swiss Chard & Spinach

3/8″ (9.5 mm) Strip

Carrot

1/4″ (6.4 mm) Slice

Celery

3″ (76.2 mm) Stick

Iceburg Lettuce

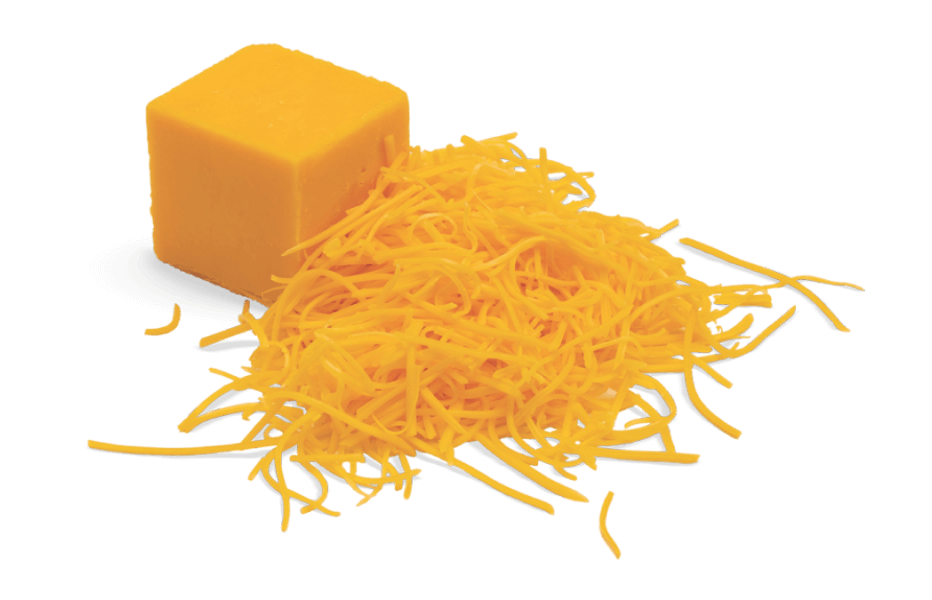

1/8″ (3.2 mm) Shred; 1-3/8 x 1‑1/2″ (35 x 38 mm) Square

Iceburg Lettuce

1-1/2″ (25.4 mm) Square

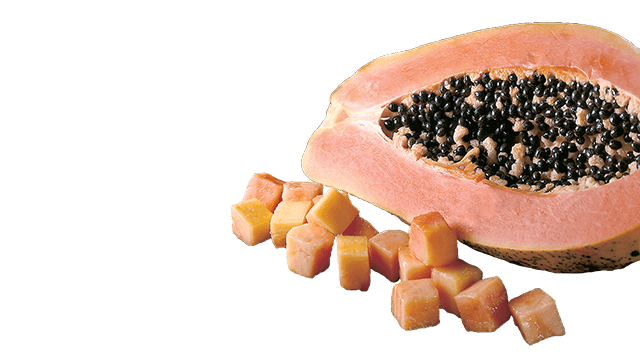

Papaya

3/4″ (19.1 mm) Dice

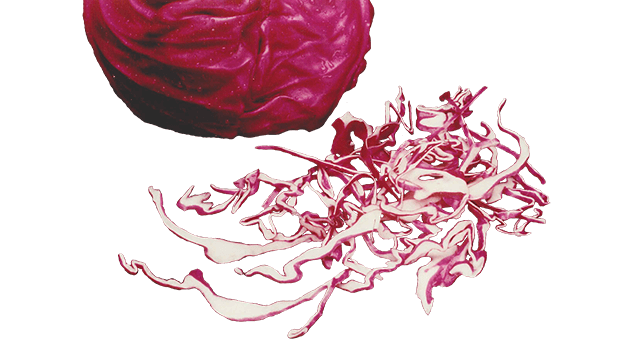

Red Cabbage

1/8″ (3.2 mm) Shred

Flat-Leaf Parsley

1/2″ (12.7 mm) Chop

Romaine Lettuce

1″ (25.4 mm) Chop

Cabbage

1/16 x 2″ (1.6 x 50.8 mm) Shred

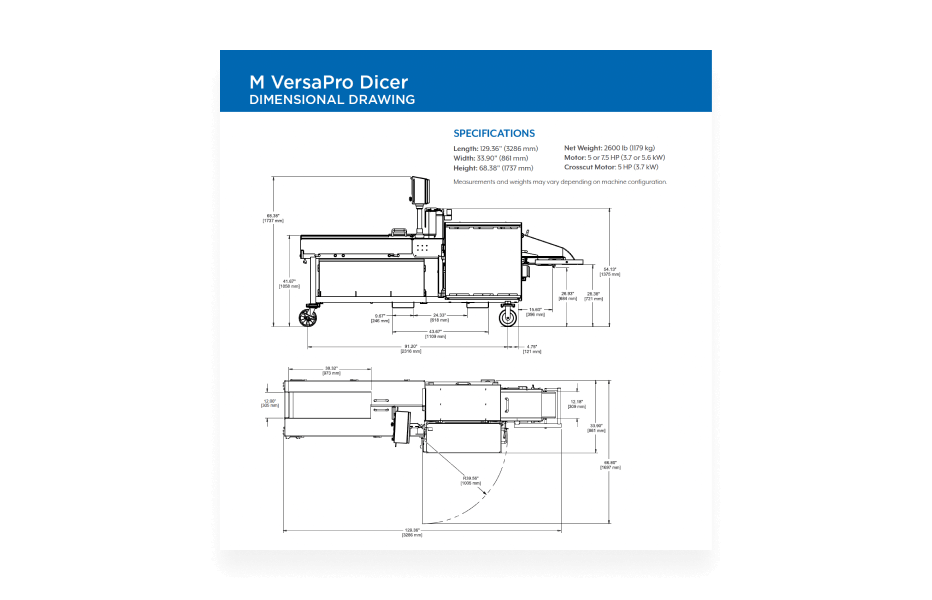

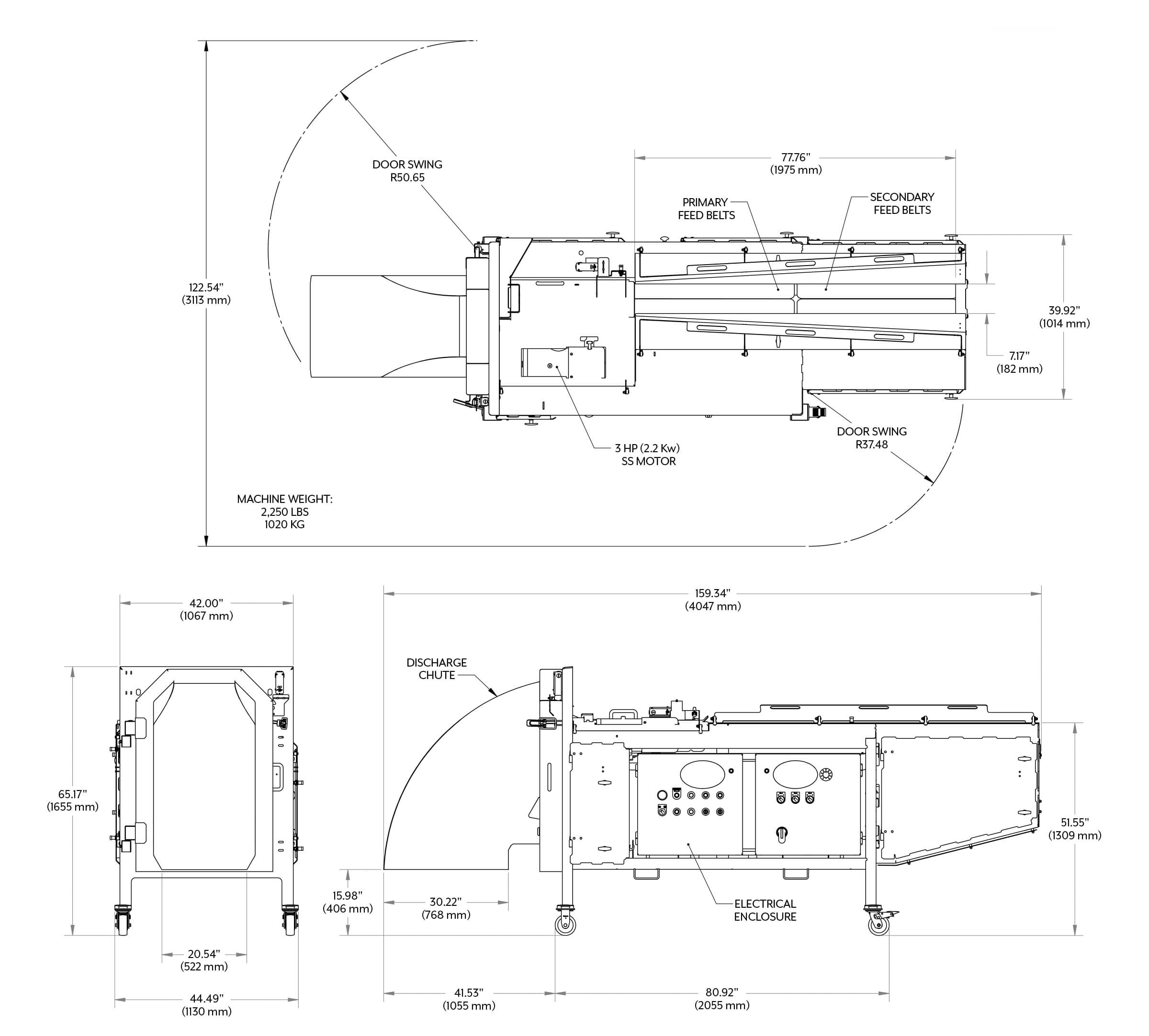

Specs

TranSlicer® 2520 Cutter

| LENGTH | 159.34″ (4047 mm) |

| WIDTH | 44.49″ (1130 mm) |

| HEIGHT | 65.17″ (1655 mm) |

| NET WEIGHT | 2250 lb (1020 kg) |

| CUTTING WHEEL MOTOR | 3 HP (2.2 kW) |

| FEED BELT MOTORS (2) | 1 HP (.75 kW) |

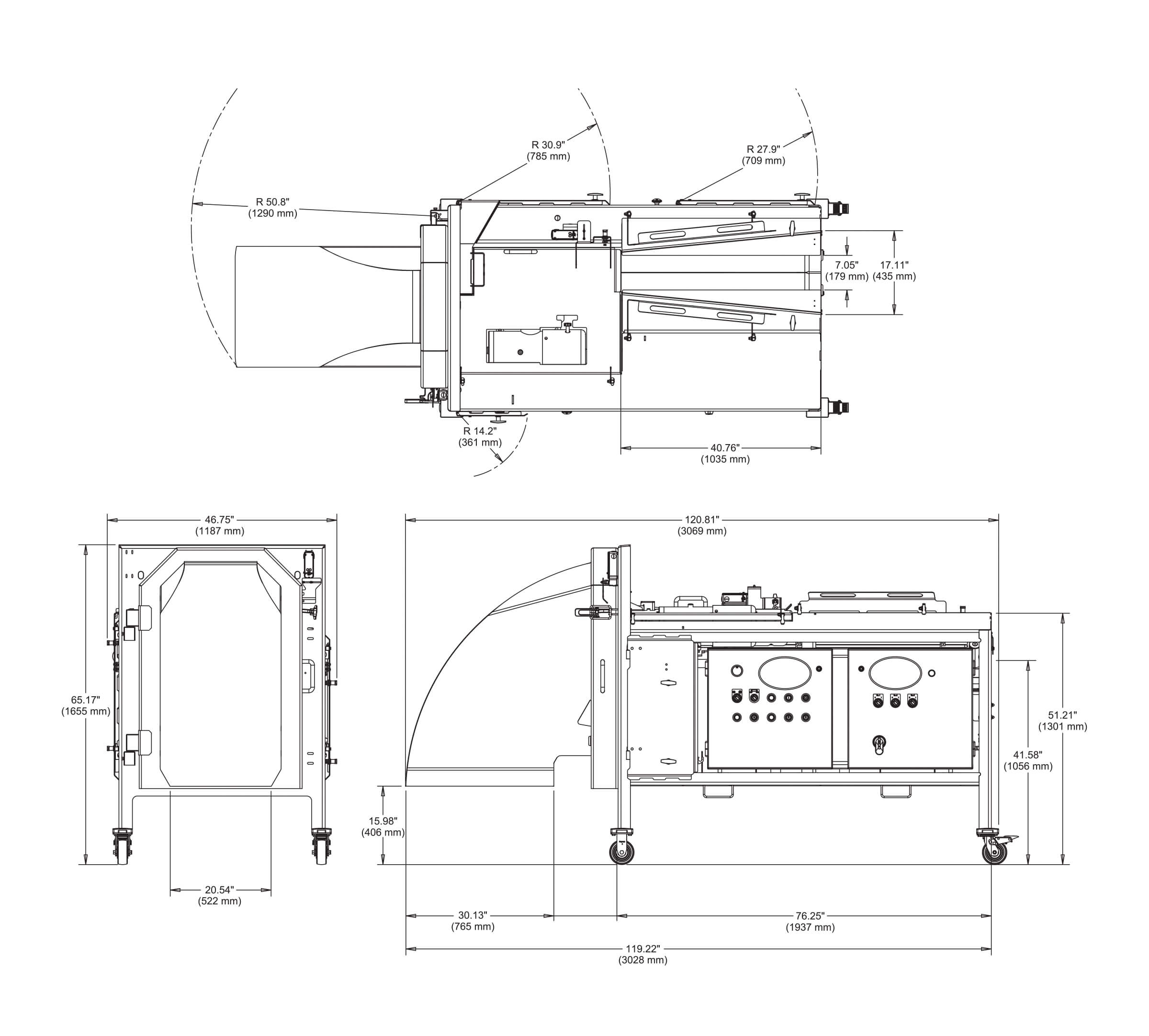

TranSlicer® 2520 Cutter – Short Frame

| LENGTH | 120.81″ (3069 mm) |

| WIDTH | 46.75″ (1187 mm) |

| HEIGHT | 65.17″ (1655 mm) |

| NET WEIGHT | 1785 lb (810 kg) |

| CUTTING WHEEL MOTOR | 3 HP (2.2 kW) |

| FEED BELT MOTOR | 1 HP (.75 kW) |

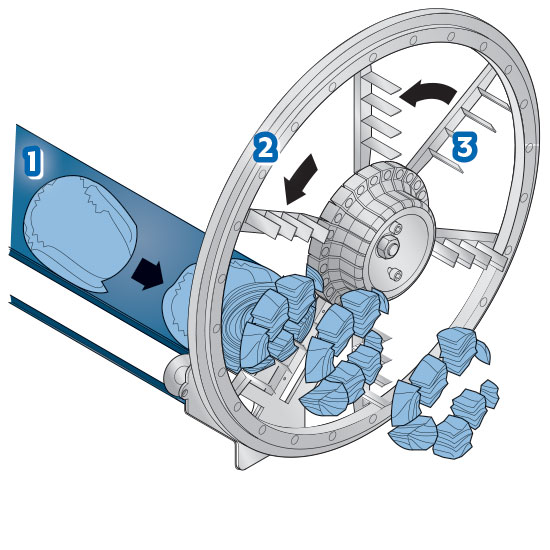

Operating Principle

TranSlicer® 2520 Cutter

- Feed Belt

- Julienne Wheel

- Julienne Knives

Knife Info

Need Help with Knives for Your Urschel Cutting Machinery?

Contact us today to get help with upgrading or replacing your knives with original Urschel parts.

Types of Cuts

Cut Category

Slicing Wheel

Flat and Crinkle Slices: 1/32 to 3″ (.8 to 76.2 mm).

Julienne Wheel

Julienne cuts ranging from 3/8 x 3/8″ to 3 x 2″ (9.5 x 9.5 mm to 76.2 x 50.8 mm) can be produced by using julienne knives on the cutting wheel.

Shredding Wheel

Shred cuts ranging from 3/8″ (9.5 mm) to approximately 3″ (76.2 mm) in length and 1/32 to 9/32″ (.8 to 7.1 mm) in slice thickness can be produced by using a combination of julienne and slicing knives to make up the shredding wheel.

Want to Test Cut Your Specific Product?

Contact Urschel to learn more about the product test cutting process.

Media & Brochures

Photography

Videos

Dimensional Drawings

Frequently Asked Questions

Ask a Question

"*" indicates required fields

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Machine Brochure TranSlicer® 2520 Cutter

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter – Short Frame

Download (link opens in new window)

Machine Brochure TranSlicer® 2520 Cutter (FR)

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter (FR)

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter – Short Frame (FR)

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter (GER)

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter – Short Frame (GER)

Download (link opens in new window)

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Machine Brochure TranSlicer® 2520 Cutter

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter – Short Frame

Download (link opens in new window)

Machine Brochure TranSlicer® 2520 Cutter (FR)

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter (FR)

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter – Short Frame (FR)

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter (GER)

Download (link opens in new window)

Fact Sheet TranSlicer® 2520 Cutter – Short Frame (GER)

Download (link opens in new window)

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.