Potato Flake Cutting and Milling Equipment for Food Processors

Urschel Laboratories offers specialized cutting and milling equipment engineered specifically for the production of high-quality potato flakes. Our machines deliver precision, efficiency, and high output, making them a trusted solution for food processors, potato product manufacturers, and R&D teams worldwide.

Optimized Equipment for Potato Flake Production

Potato flakes are a key ingredient used in instant mashed potatoes, snack foods, baking applications, and as binders in processed foods. Urschel designs cutting and milling solutions that meet the specific requirements of potato flake production, providing processors with reliable, high-capacity equipment that supports consistent product quality.

Cutting and Milling Machines Built for Efficiency

Urschel’s potato flake cutting and milling equipment is built to maximize yield while reducing waste. Our machines operate continuously, delivering high throughput with minimal downtime. Hygienic designs ensure food safety compliance while simplifying cleanup and maintenance, allowing for uninterrupted production schedules.

Recommended Cutting Machines for Potato Flake Processing

Urschel recommends the following machines for optimal potato flake cutting and milling:

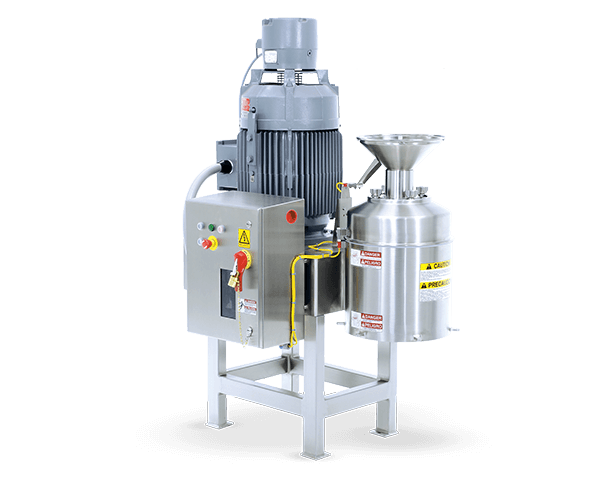

- Comitrol Processor Models: Designed for precise particle size reduction critical to producing uniform potato flakes.

Both machines feature user-friendly operation, easy cleaning, and adaptability to a range of production volumes and specifications.

Advantages of Urschel Flake Cutting Equipment

- Precision control over particle size for consistent flake texture

- Minimal maintenance requirements to maximize uptime

- Easy cleanup to support hygiene and food safety

- Scalable solutions for both pilot and full-scale production lines

Partner with Urschel for Test Cuts and Support

Urschel offers free test cutting services to help processors evaluate equipment performance with their specific product requirements. Our experienced team works directly with clients to recommend customized solutions, ensuring optimal cutting performance and long-term production success.

Note: Hundreds of pounds per hour up to thousands of pounds per hour; capacities vary depending on condition of materials, method of feeding, and other variables. Where capacities are listed, it is assumed product will flow in a smooth, uninterrupted manner through an Urschel® machine that is in optimum condition. Capacities listed are an indication of potential results.

Slicers

Dicers

Shredders

Milling Equipment

Others

Locate My Sales Rep

Test Cut Your Product

Contact Urschel Support