Why Urschel is Ideal for Cheese Milling & Granulating

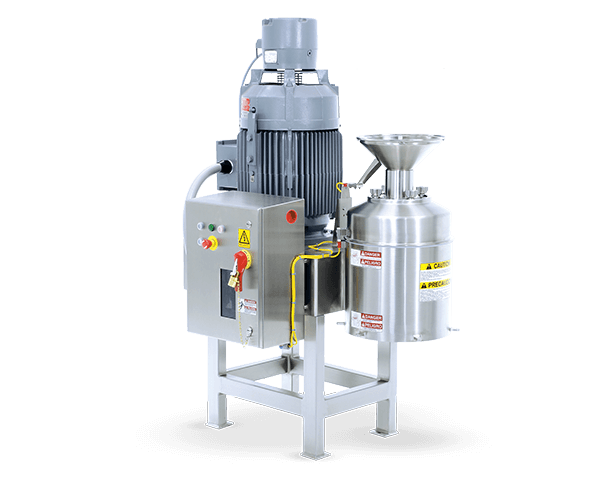

Urschel’s cheese-milling and granulating systems are engineered for high-capacity, uniform size reduction — whether you’re looking to produce fine granulates, powders, flakes, or smooth purees. By combining sanitary, stainless-steel construction with appropriate cutting heads and efficient impeller-driven milling technology, these solutions minimize heat buildup and product stress while preserving cheese quality and flavor. With throughput ranging from hundreds to thousands of pounds per hour (depending on cheese type and feed method) — and the flexibility to handle everything from parmesan hard cheeses to soft curds or ricotta — Urschel helps ensure consistent texture, reduced waste, and optimized yield. Plus, with on-site test-cutting and expert support, processors can fine-tune cut size and method to match exact application needs before committing to full-scale production.

News & Media

International Food Marketing & Technology – April 2025

Note: Hundreds of pounds per hour up to thousands of pounds per hour; capacities vary depending on condition of materials, method of feeding, and other variables. Where capacities are listed, it is assumed product will flow in a smooth, uninterrupted manner through an Urschel® machine that is in optimum condition. Capacities listed are an indication of potential results.

Below you will find our selection of cheese milling/granulating machines. Each of the following cheese mills/granulators offers different options and cuts depending on your application.

Slicers

Dicers

Shredders

Milling Equipment

Others

Locate My Sales Rep

Test Cut Your Product

Contact Urschel Support