TranSlicer® 2510 Cutter

Large Product, High Capacity Slicer/Shredder

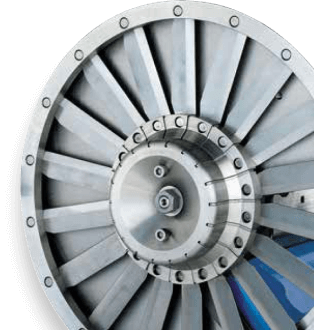

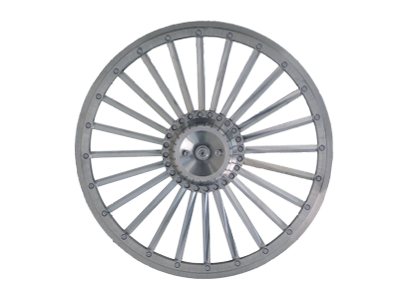

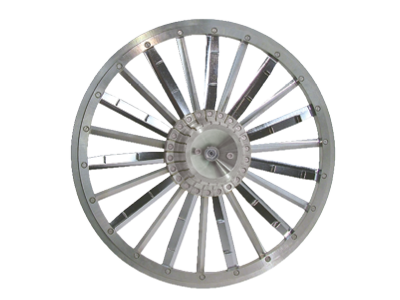

In the TranSlicer® Series, the TranSlicer® 2510 Cutter is the precursor to the TranSlicer® 2520 Cutter. The capable TranSlicer® 2510 Cutter is ideally suited for leafy vegetables, popular applications include: romaine, iceberg, kale, radicchio, cabbage, spinach, celery, cucumbers, eggplant, honeydew, cantaloupe, and leek.

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

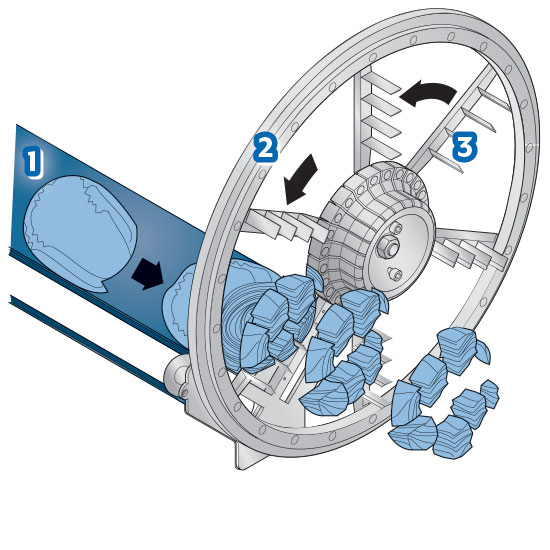

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.