Affinity® CD-L Dicer

Dried or Sticky Fruits

The Affinity® CD-L successfully processes difficult-to-cut products including dried, sticky, or candied fruits and bakery products.

-

Key Features

-

Applications

-

Specs

-

Knife Info

-

Types of Cuts

-

Media & Brochures

-

FAQs

Key Features

SMALL FOOTPRINT

The Affinity® CD-L Dicer takes up minimal space on the production floor.

EASE OF SANITATION AND MAINTENANCE

Rounded tube frame and angled/rounded surfaces ease washdowns and deter bacterial growth. Hinged swingaway panels ease maintenance.

PROCESS DIFFICULT-TO-CUT PRODUCTS

The Affinity® CD-L Dicer excels at processing challenging, difficult-to-cut applications such as dried or candied fruits.

SANITARY ZONE DESIGN

Sanitary design with all mechanical components completely separate from the food zone.

OPTIONAL OIL SPRAY SYSTEM

Optional integrated oil spray system lubricates circular knives to assist in the processing of sticky products.

HIGH CAPACITY PRODUCTION

High capacity capabilities and continuous operation for uninterrupted production.

HEAVY DUTY

Optional outboard bearing supports the cutting spindles to assist in the processing of tough, heavy-duty applications.

URSCHEL SERVICE & SUPPORT

Urschel cutting machinery is backed by solid service and support. Urschel customer service is just as reliable and dependable as the rugged equipment Urschel manufactures.

Applications

The new Affinity® CD-L Dicer produces uniform dices in the small to intermediate size range. The CD-L combines the utility of Urschel Models CD-A and L-A, plus working design elements from the Affinity Integra® Dicer. Processors replacing Model L-A’s with the CD-L achieved more than twice the capacity.

Sanitary in design, the food zone is completely separated from the mechanical zone. Hinged access panels ease maintenance and washdowns, and offer full access to conveniently changeover parts. Feed spindle, feed drum, and 5 HP (3.7 kW) motor work effectively with the cutting components in the successful processing of dried fruits and other products. Optional integrated oil spray system lubricates circular knives to assist in the processing of sticky products. Equipped with stainless steel product contact parts, the dicer offers simple operation at the push of a button and may be operated at high or low speed depending on processing goals. The dicer features continuous operation and is designed for easy cleanup and maintenance. Maximum infeed product should not exceed 1/2″ (12.7 mm) depending on the compressibility of the product.

Almond

1/8″ (3.2 mm) Dice

Chocolate Covered Toffee Bar

3/16″ (4.8 mm) Granulation

Cream Filled Wafer Cookie

1/4″ (6.4 mm) Granulation

Pecan

3/16″ (4.8 mm) Granulation

Bacon Jerky

1/4″ (6.4 mm) Dice

Fruit Leather

3/8″ (9.5 mm) Dice

Chocolate

1/8″ (3.2 mm) Granulation

Dried Apricot

3/8″ (9.5 mm) Dice

Dried Date

3/8″ (9.5 mm) Dice

Sugar Infused Cranberry

5/32″ (4 mm) Strip

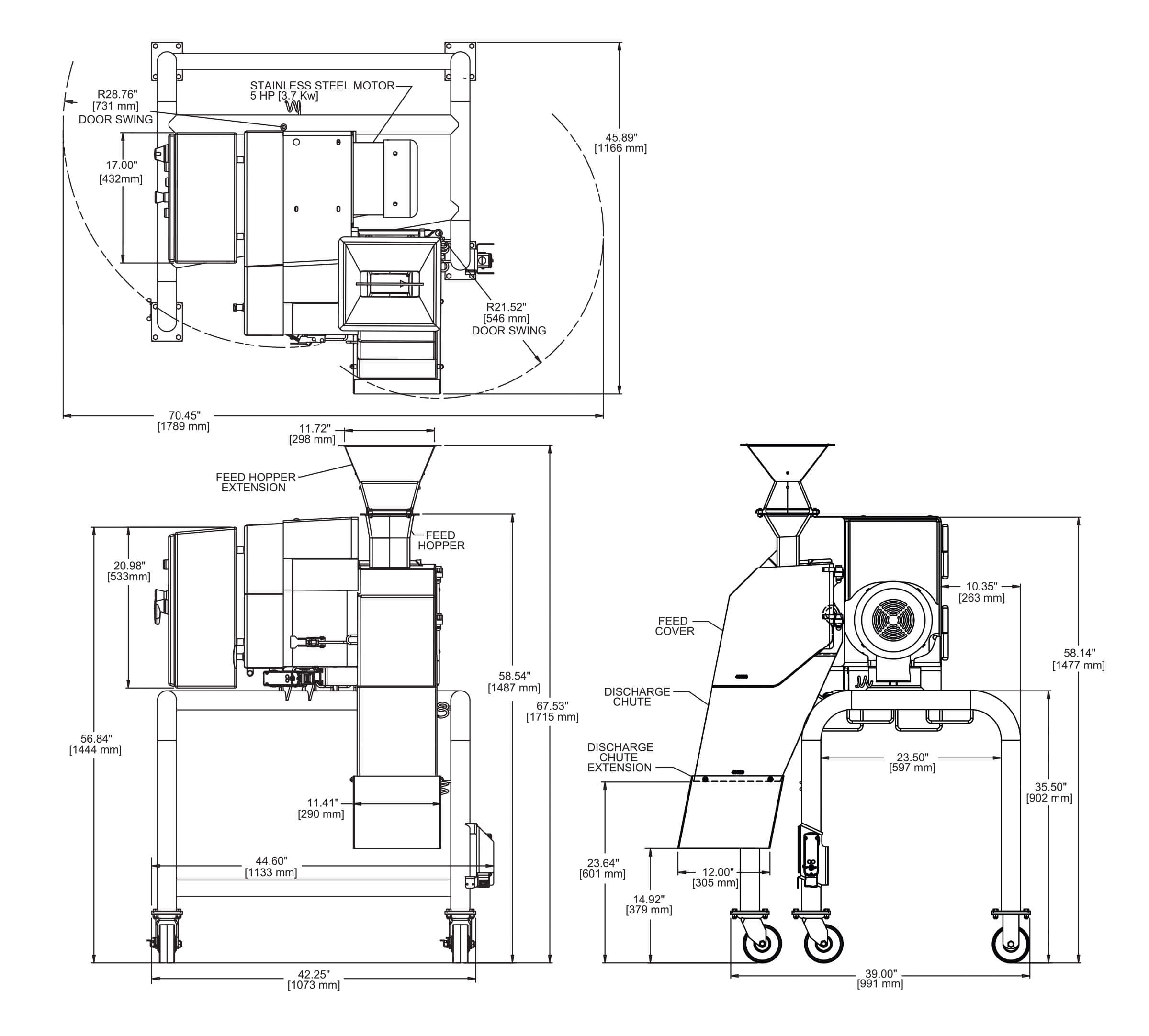

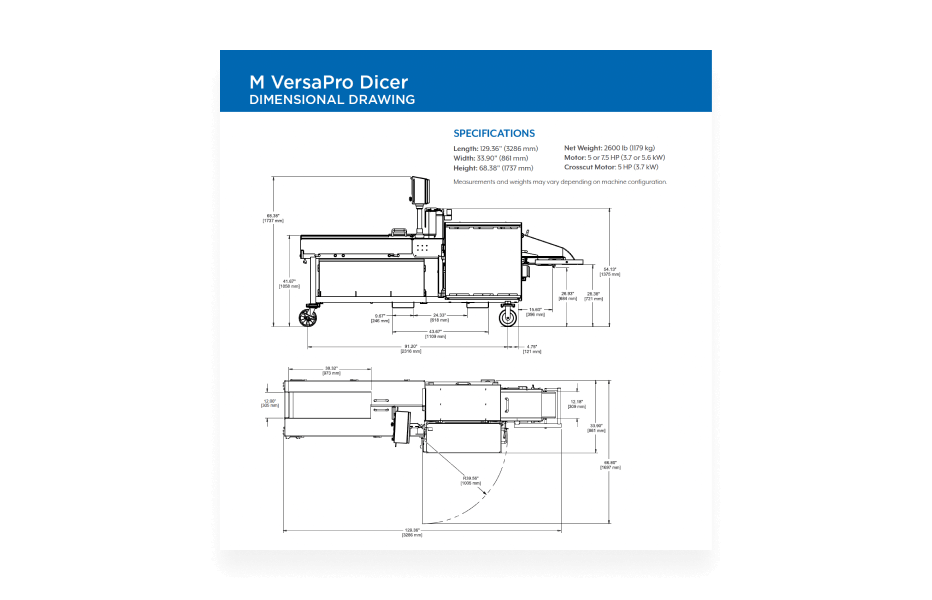

Specs

| LENGTH | 42.25″ (1073 mm) |

| WIDTH | 45.89″ (1166 mm) |

| HEIGHT | 67.53″ (1715 mm) |

| NET WEIGHT | 1100 lb (499 kg) |

| MOTOR | 5 HP (3.7 kW) |

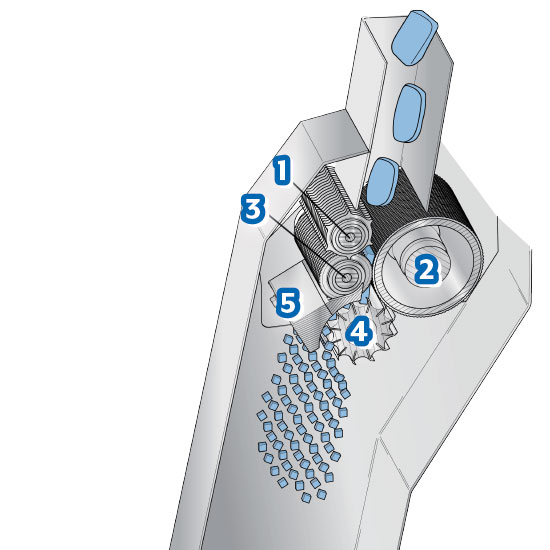

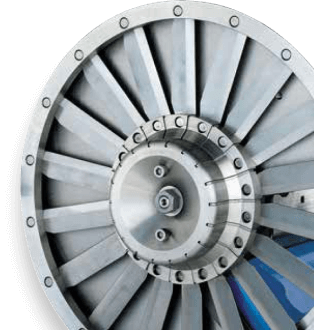

Operating Principle

Affinity® CD-L Dicer

- Feed Spindle

- Feed Drum

- Circular Knives

- Crosscut Knives

- Stripper Plate

Knife Info

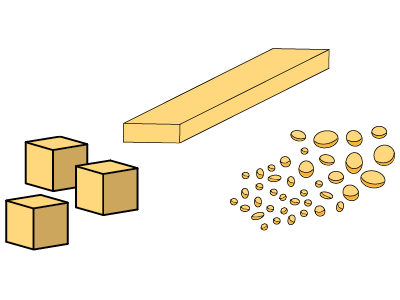

2-Dimensional Cutting

Dices/Strips/Granulations

2-dimensional cutting is achieved by using the appropriate circular and crosscut spindle set-up.

Controlled Precision

Specially Designed Feed Drum

Specially designed feed drum profile assists in the positive movement of product throughout the cutting components.

Takes on Heavy Duty Applications

Outboard Bearing

Optional outboard bearing works with heavy duty knives and components to overcome tough applications such as frozen-tempered bacon dicing.

Cantilevered Cutting Spindles

Simplify Cleaning and Maintenance

Lightweight, cantilevered spindles remove completely from the machine for cleaning and maintenance.

Need Help with Knives for Your Urschel Cutting Machinery?

Contact us today to get help with upgrading or replacing your knives with original Urschel parts.

Types of Cuts

Dice/Strip/Granulate

2-dimensional cutting is achieved by using the appropriate circular and crosscut spindle set-up.

Circular Knife Cuts: 1/8 to 2″ (3.2 to 50.8 mm)

Crosscut Knife Cuts: 1/8 to 1-1/2″ (3.2 to 38.1 mm)

Want to Test Cut Your Specific Product?

Contact Urschel to learn more about the product test cutting process.

Frequently Asked Questions

Ask a Question

"*" indicates required fields

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Machine Brochure Affinity® CD-L Dicer

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer

Download (link opens in new window)

Machine Brochure Affinity® CD-L Dicer (FR)

Download (link opens in new window)

Machine Brochure Affinity® CD-L Dicer (RU)

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer (FR)

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer (DE)

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer (PL)

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer (POR)

Download (link opens in new window)

Find My Sales Rep

Where are you located?

Search United States

Search Globally

Looking for Global Sales Reps?

Looking for U.S. Sales Reps?

Brochures & Guides

Machine Brochure Affinity® CD-L Dicer

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer

Download (link opens in new window)

Machine Brochure Affinity® CD-L Dicer (FR)

Download (link opens in new window)

Machine Brochure Affinity® CD-L Dicer (RU)

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer (FR)

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer (DE)

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer (PL)

Download (link opens in new window)

Fact Sheet Affinity® CD-L Dicer (POR)

Download (link opens in new window)

The Urschel Difference

As the global leader in food cutting technology, Urschel continues to lead the world in the manufacturing and selling of industrial cutting equipment to the food processing and allied industries. The company continues to expand around the globe to grow alongside this ever-changing, dynamic industry, while maintaining its headquarters and manufacturing facility in northwest Indiana, centrally located in the heart of the United States.

1

High-capacity Urschel cutting machinery is manufactured at our headquarters in Indiana, U.S.A.

2

Customer service focused setting the industry standard in food cutting technology.

3

100% employee-owned and operated for the highest quality and attention to detail possible.