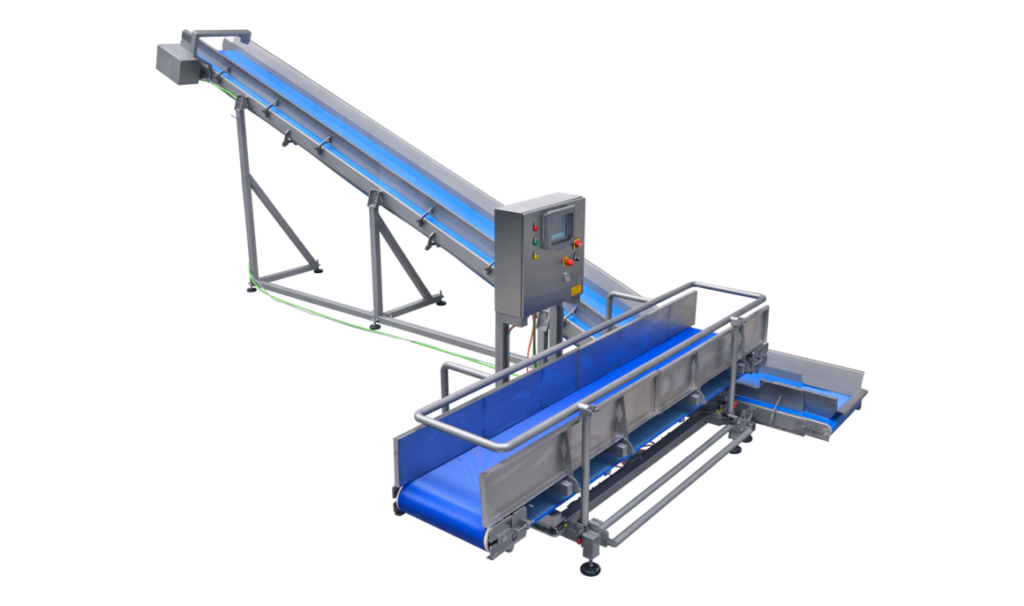

Recipe weighing belt

Conveying, Weighing

Automatic weighing of up to ten product components according to preset recipes – up to 99 recipe mixtures can be individually set. The weighing belt is especially designed for mixing salads and vegetables according to customized recipes.

- Features

- Specs

- Resources

Overview

Precise weighing of vegetable and salad products according to selectable recipe mixtures

The recipe weighing belt offers the option of weighing up to ten product components according to specified recipes. Up to 99 individual recipe mixtures can be stored using the touch panel, thus always ensuring up-to-date recipes and a consistently good quality of the mixing ratios.

Operation is very easy and user-friendly. The touch panel is used to set the recipes for the batch weighing of the mixed products. Once the target weight has been reached, the weight of the next product is displayed. Here, the software also offers the option of inverted weighing, which enables the operator to begin the next batch with the last component of the previous batch. The recipe weighing belt is equipped with a tapping frame that enables the emptying of crates of raw materials.

The robust system is designed especially for use in the automated processing of food products. The recipe weighing belt can be optimally integrated into various process flows. In combination with a ascending conveyor belt, for example, the product mixtures can be fed to a downstream GEWA washing machine or packaging line.

Your Benefits

- User-friendly and safe operation by means of a touch panel and foot-operated switch

- Easy preparation and saving of up to 99 recipe mixtures

- Easy cleaning and maintenance work due to an open and hygienic design

Highlights

99 memory locations for recipe mixtures with up to 10 product components

The recipe mixtures that can be individually prepared can be saved very easily via the touch panel. A recipe mixture containing up to 10 different product components can be created, and the desired target weight of each component can be saved, e.g. 100 kg (220 lb) iceberg lettuce, 30 kg (66 lb) lollo rosso, 25 kg (55 lb) carrot strips and 25 kg (55 lb) cut cabbage.

Light indicator for easy weighing control

A light indicator and the display on the touch panel shows the current weight of the component to the operator and signalizes when the target weight has been reached. The operator confirms the weight via a sturdy foot-operated switch and is then immediately shown the target weight of the next component.

Optimal maintenance and easy cleaning

The open and hygienic stainless steel construction allows easy cleaning. The belt tension can be released very easily, and the belt can be removed sideways.

Specs

| Operator | Semi-automatic |

| Electrical Power | Power: 1.4 kW (1.9 HP) Voltage: 230 V N/PE Frequency: 50 Hz |

| Dimensions | L x W x H: 3000 x 1200 x 1600 mm (118.1 x 47.2 x 63″) Belt width: 500 mm (19.7″) Belt speed: 0.63 m/s |

Industries

Vegetables