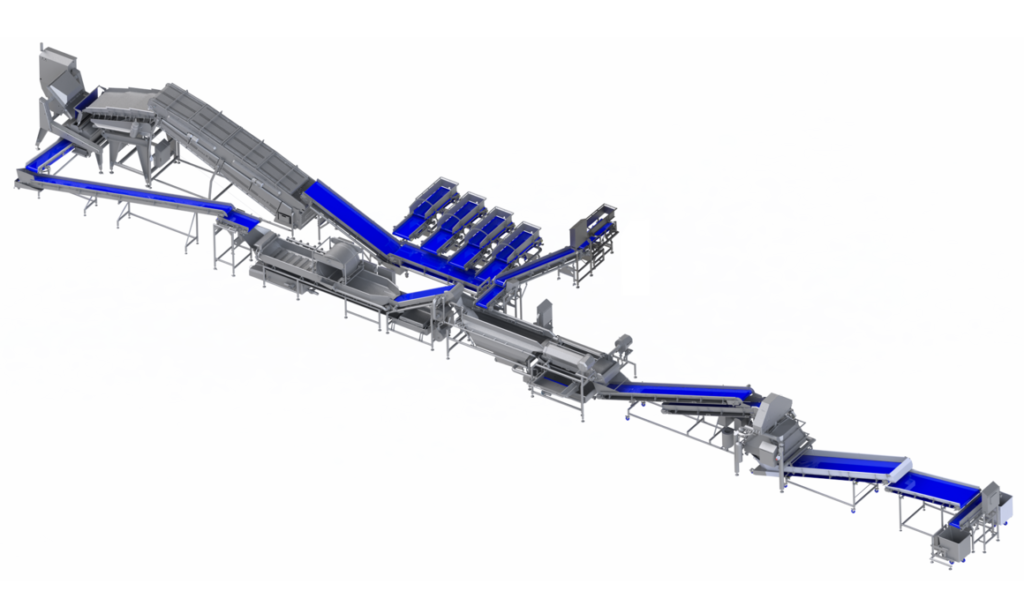

Processing line for lettuce and leafy vegetables

Disinfection, Washing, Drying, Mixing, Conveying, Weighing

A networked, fully automated system for weighing, sorting, washing and drying salad leaves – e.g. baby leaf or mixed lettuce – and leafy vegetables: For maximum hygiene and efficiency, gentle processing and high product quality.

Up to 2,000 kg (4,400 lb)/h max. capacity.

- Features

- Specs

- Resources

Overview

Innovative and networked – intelligent and efficient weighing, washing, drying and sorting

The fully automated, networked processing line integrates innovative washing and drying technology from KRONEN with a dynamic weighing system from iWEIGH and mechanical and optical sorting solutions from HiTec Food Systems. All components of the line are networked. This ensures constant, low-interruption processing and low personnel requirements. At the same time, a cost-efficient process, high capacities and maximum quality in production are guaranteed. The innovative system sets new standards in terms of hygiene.

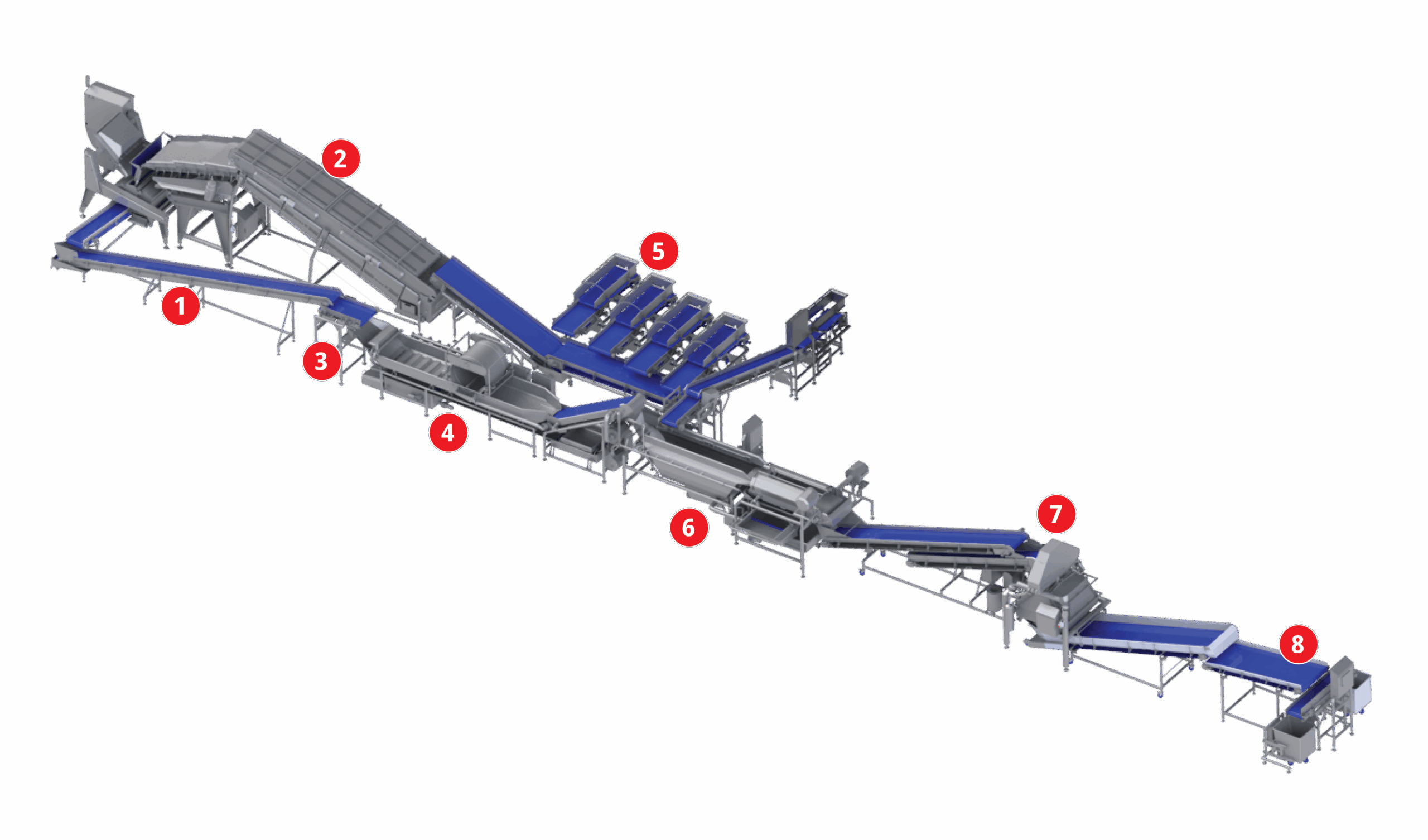

The following machines or solutions are integrated:

- Weighing in and conveying: Flow Weigh Belt System, a dynamic recipe weighing beltby iWEIGH

- Sorting: Mechanical sorting system by HiTec Food Systems and visual sorting system by Optimum

- Conveying and weighing: PLUS inclined conveyor belt and a weighing belt by iWEIGH, which communicates with the recipe weighing belt for an optimized product flow

- Pre-washing: GEWA AF “Active Flume” washing system with belt outfeed, including a water chute for gentle product intake, insect and fine particle removal with an extended contact surface and an air section with an integrated sand trap.

- Washing: GEWA XL HELICAL washing machine with belt outfeed, including a water chute for a gentle product intake, sand trap sedimentation unit and lateral fine particle removal drum

- Drying: K850 drying system including water drainage with a flexible drip guard on the belts as well as advance dewatering

- Further transport and weighing: Standard trolley weighing system by iWEIGH for continuous filling of standard containers up to 300 l

Application options and capacities:

The system is optimized for processing light, delicate, leafy products such as baby leaf lettuce as well as mixed salads, which are weighed in fully automatically. Leafy vegetables such as spinach, chard, radicchio, Chinese cabbage or kale can also be processed.

The capacity depends on the product. The line processes, for example:

- Up to 1,000 kg (2,200 lb)/hour of baby leaf lettuce

- Up to 2,000 kg (4,400 lb)/h of mixed salad (e.g. sweet leaf with 30% carrot and cabbage)

For the processing of non-floating products, another GEWA washing machine can be integrated instead of the GEWA AF.

Your Benefits

- Fully automated –for maximum efficiency in production, high capacities and a low personnel requirement

- SMART: continuous processing due to communication between the machines and visual displays for the operators.

- Integrated high-quality, innovative washing and drying technology, including the GEWA AF, GEWA XL, K850

- Sets new standards in hygiene for food production with maximum safety

- Dynamic weighing and dispensing as well as mechanical and optical sorting with integrated solutions from iWEIGH and HiTec Food Systems

- Designed for gentle processing and high product quality – especially for light, sensitive products

Highlights

SMART Solutions for intelligent, networked production

With the SMART option, KRONEN makes communication-enabled machines and processing lines possible. Wherever production managers, technicians or foremen might be, they can check the production status of the machine or line on their laptop or mobile device at any time. The collected data can be used to make production processes even more transparent and efficient, for example in terms of productivity, flexibility, quality and safety. Do you have any special requirements? We can develop an individual, made-to-measure solution for you.

Continuous and gentle processing of high capacities

The production line handles lettuce and leafy vegetables in a continuous process and therefore requires only a small number of personnel. The communication between the SMART-version machines and the visual displays for the machine operators facilitates a reliable, constant and uninterrupted production flow. This in turn ensures high processing capacities and maximum efficiency and quality in production.

Automatic, hygienic and flexible processing

The KRONEN cutting, washing and drying machines are also designed for frequent product or recipe changes during a production shift. The belt cutting machines guarantee quick knife replacement. The washing machines fully empty in a very short time. The drums of the large centrifuges are blown dry during emptying. The hygienic design of the KRONEN machines allows all areas to be easily accessed and makes the machines easy to clean. User-friendly operation and the safety of operating personnel are guaranteed.

Complete solutions from a single source

KRONEN is a reliable partner, even when it comes to implementing automated processing lines. With a high level of planning and consulting expertise, the company implements the right solution for every customer requirement. KRONEN offers complete lines from a single source and integrates suitable machines from partners as required.

Specs

| Max. Capacity | up to 2,000 kg (4,400 lb)/h |

| Operator | Automatic |

| Sanitation | Wet disinfection |

| Loading Type | Continuous |

- PLUS inclined conveyor belt

- Mechanical sorting system by HiTec Food Systems

- Weighing belt by iWEIGH

- GEWA AF with belt outfeed

- Flow Weigh Belt System by iWEIGH

- GEWA XL with belt outfeed

- K850 drying system

- Standard trolley weighing system with conveyor belt by iWEIGH

Industries

Vegetables