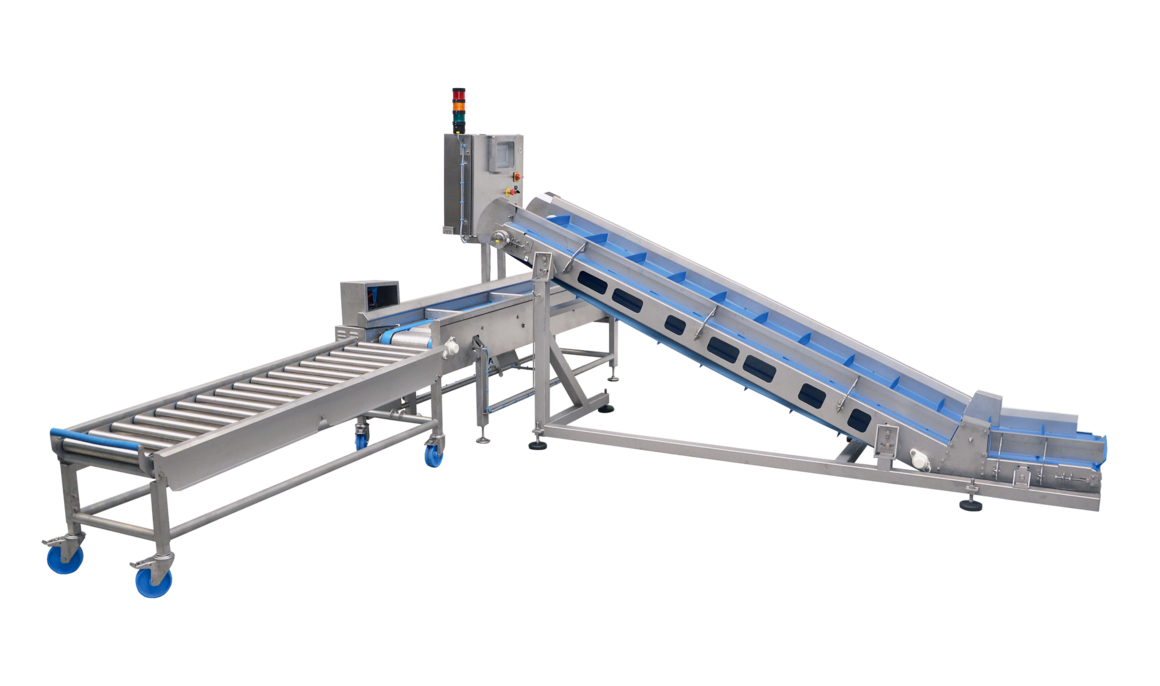

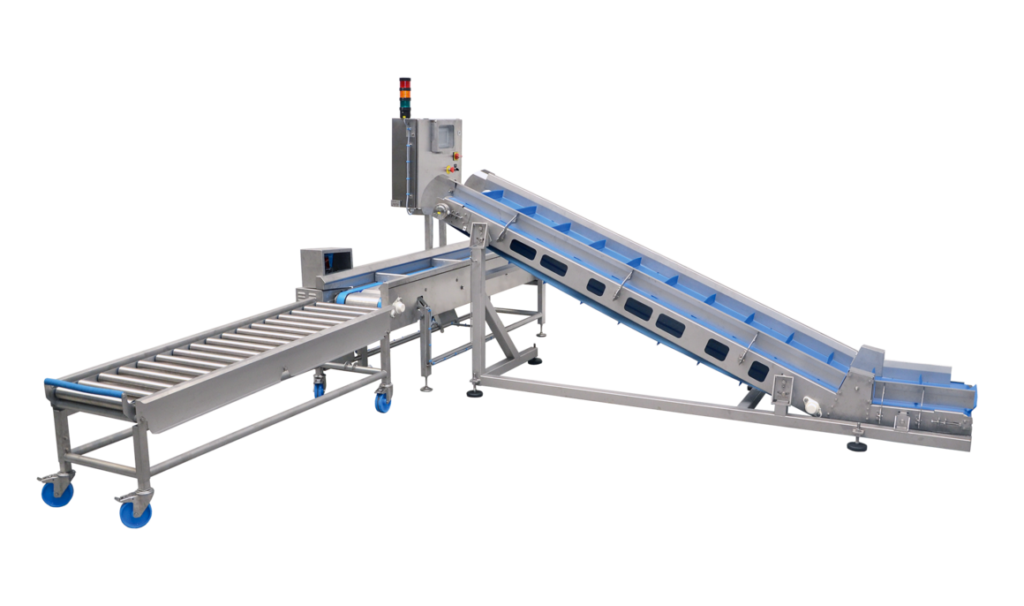

KWS crate weighing system

Weighing

Processed products such as cut vegetables and lettuce are automatically filled into crates, for example Euronorm containers, and weighed within seconds.

- Features

- Specs

- Resources

Overview

Filling within seconds and reliable weighing directly into crates

The KWS crate weighing system is an ideal solution for the automatic weighing of products in Euronorm crates (600 x 400 x X mm). An existing or a supplied filling belt is controlled via the KWS for optimal filling of the crates.

The standard equipment of the KWS includes the intake of three crates: two empty crates and the crate to be weighed. The crates are automatically guided over the sturdy weighing platform. Weight-accurate filling begins after the crate has been tared. During the filling process, the infeed belt can be controlled at two speeds: first for coarse filling and at the end of the filling process for fine filling at a slower speed. As soon as the specified (programmable) filling weight has been reached, the filled crate is automatically forwarded onto an optionally available roller conveyor with a docking station that is mechanically connected to the KWS. A new empty crate is automatically added and positioned on the weighing platform.

The robust system is designed especially for use in automated food processing. The KWS can be optimally integrated into the process flow, in particular at the end of a production line.

A label printer can be installed as a practical optional addition, for example for labels per crate or per pallet (after a certain number of crates).

Your Benefits

- Automatic weighing into a container

- Automatic infeed and discharge of the container

- Control for an infeed conveyor to the crate weighing system included as standard

- Optional possibility to further process the usage data: kg per crate, capacity per hour, crates per hour, etc.

Highlights

Precise control unit of the infeed belt as standard

During filling, the system enables the infeed belt to be controlled at two speeds: initially for coarse filling and then, at the end of the filling process, fine filling at a slower speed.

A slipping clutch on the drive unit ensures safety

The use of a slipping clutch on the infeed belt ensures a high level of work safety and thus considerably reduces any risk of injury.

Hygienic crate transport via belts

A high-quality belt – instead of a chain – is used for transporting the containers on the infeed belt, thus offering a safe and hygienic solution.

Specs

| Loading Type | Semi-automatic |

| Electrical Power | Power: 1.5 kW (2 HP) Voltage: 400 V N/PE Frequency: 50 Hz |

| Dimensions | LxWxH: 2663 x 749 x 1600 mm (104.8 x 29.5 x 63 in) (1836 mm (72.3″) with signal traffic light system) Weight: 240 kg (529.1 lb) Infeed/placement height: 595 mm (23.4″) Outfeed/placement height: 595 mm (23.4″) Belt width: 400 mm (15.8″) Belt speed: max 0.6 m (23.6″)/min |

Industries

Vegetables

Fruit

Salads

Fish

Meat

Vegan procuts

Baked goods