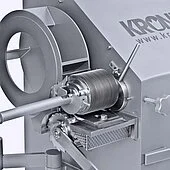

KUJ-V cube, strip & slice cutting machine

Cutting

The high-performance machine cuts vegetables, fruit and meat into cubes, strips or slices – in a single operation and with exact and perfect quality, even with very fine cuts.

2,500 kg (5,500 lb)/h Max. capacity

- Features

- Specs

- Resources

Overview

For fine cubes, sticks, strips and slices: cut large quantities up to 2,500 kg (5,500 lb) per hour easily and precisely

The KUJ-V cuts even the finest cubes, strips, sticks and slices cleanly and precisely in large quantities for the food and catering industry. In just one operation, the machine processes vegetables (e.g. carrots, potatoes, onions and peppers), fruit (e.g. apples, kiwis and melons) or meat, ham, bacon and fish.

The standard built-in frequency converter with seven adjustable speeds also ensures gentle cutting and dicing. Fine cubes measuring 3 x 3 x 3 mm (3/32 x 3/32 x 3/32″), rice cuts (e.g. from broccoli and cauliflower stalks) measuring 3 x 3 x 5 mm (3/32 x 3/32 x 1/4″), long slices of vegetables such as eggplants/aubergines, zucchini/courgettes and cucumbers, or fine 2 x 2 mm (1/16 x 1/16″) sticks for dips, soups, sauces and salads can also be produced. In addition, even sensitive products such as strawberries, beetroot, mushrooms, tomatoes and zucchini/courgettes are processed perfectly. Meat and fish (e.g. salmon and octopus), both cooked and frozen, or hard-boiled eggs and cheese (e.g. mozzarella) can also be diced with the KUJ-V.

- Diameter: 85 mm (3.5″)

- Length: 120 mm (4.7″) as standard, with the optional special rotor up to 200 mm (8″)

The GS 10-2 or GS 20 belt cutting machines are suitable for other products such as leaf lettuce and herbs.

Product requirements:

Your Benefits

- Cuts cubes, strips and slices – even very fine (e.g. ultra-fine 3 x 3 x 3 mm (3/32 x 3/32 x 3/32″) cubes).

- High performance with precise and consistent cutting quality.

- Easy operation and cleaning as well as maximum safety.

- Extensive cutting tools for slices from 2 to 20 mm (1/16 to 3/4″), strips from 2 x 2 to 20 x 20 mm (1/16 x 1/16 to 3/4 x 3/4″) and cubes from 3 x 3 x 3 to 20 x 20 x 20 mm (3/32 x 3/32 x 3/32″ to 3/4 x 3/4 x 3/4″).

- Compact design for a low space requirement – as a stand-alone machine or for integration into a processing line.

Highlights

Easy roller and blade replacement

The knife rollers can be removed and installed quickly and safely. This enables simple, rapid product changes and also reduces cleaning times. The rollers can be changed in a few minutes using the special tools supplied. The blades in the rollers are replaceable and can be resharpened or renewed, reducing follow-up costs.

Easy and safe operation, cleaning, and maintenance

The products are optimally fed into the removable feeding hopper either manually or optionally via an ascending conveyor belt, cut, and discharged via a conveyor belt or ejected into a container. The ergonomic hygienic design with continuously welded edges and the knife box door with a 90-degree swivel function make cleaning quick and easy. Central lubrication and easily accessible housing facilitate servicing.

Specs

| Max. Capacity | 2,500 kg (5,500 lb)/h (The capacity depends on factors such as the product.) |

| Operator | Automatic |

| Electrical Power | Power: 1.1 kW (1.5 HP) Voltage: 230 V N/PE Frequency: 50 Hz |

| Dimensions | L x W x H: 1106 x 977 x 1491 mm (43.5 x 38.5 x 58.7″) Weight: 204 kg (450 lb) Infeed/placement height: 1491 mm (58.7″) Outfeed/deliver height: 472 mm (18.6″) |

| Miscellaneous | Diameter of raw product: max. 85 mm (3.4″) Length of raw product: max. 120 mm (4.7″) – optionally 200 mm (8″) Cutting thickness: slices: 2 to 20 mm (1/16 to 3/4″ strips: 2 x 2 to 20 x 20 mm (1/16 x 1/16 to 3/4 x 3/4″) cubes: 3 x 3 x 3 to 20 x 20 x 20 mm (3/32 x 3/32 x 3/32 to 3/4 x 3/4 x 3/4″) |

Industries

Vegetables

Fruit

Meat