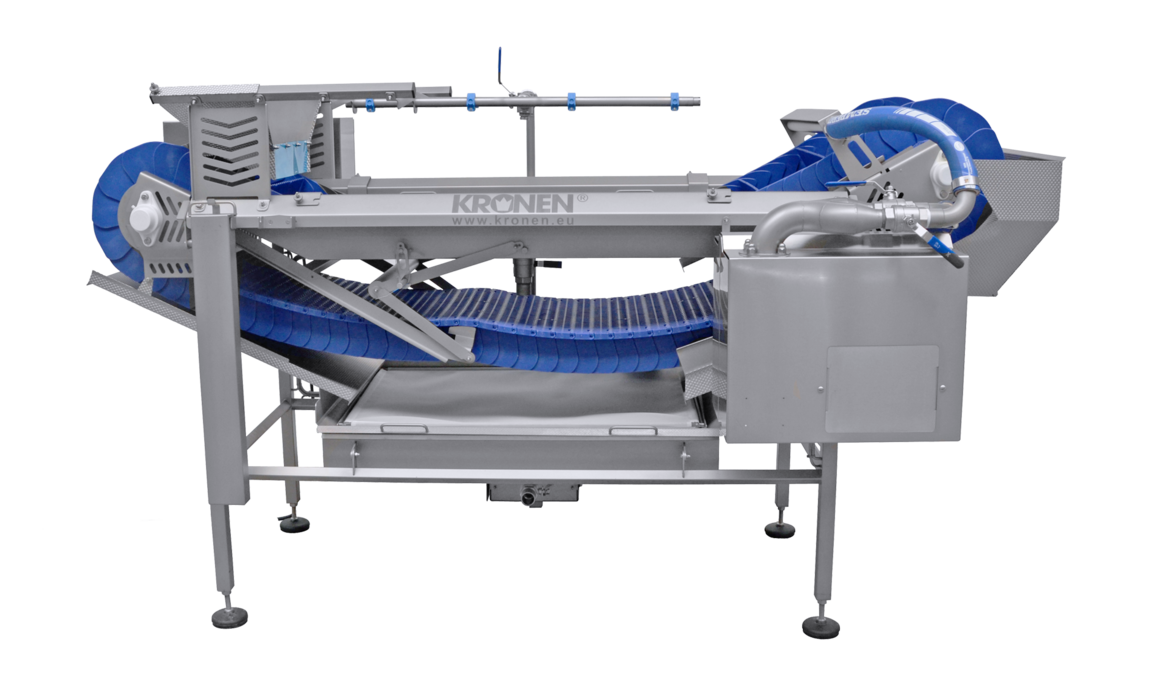

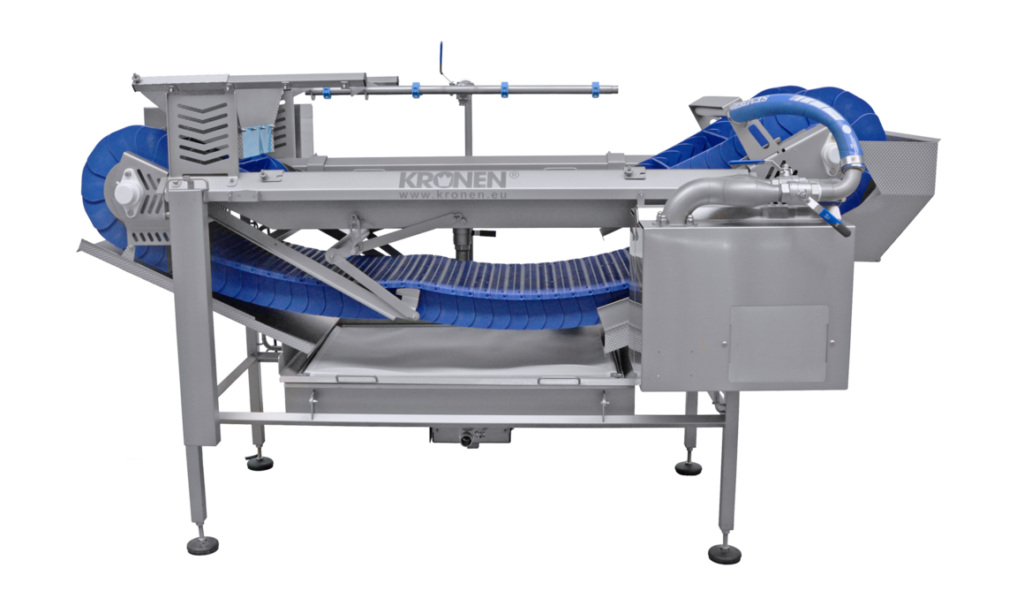

KDB 120 dipping bath

Disinfection

In the KDB 120 dipping bath, cut fruit and vegetables are treated with a minimum amount of water and therefore also a reduced amount of additives in order to increase shelf life and reduce the germ load on product surfaces.

up to 750 kg (1654 lb) /h Max. capacity

- Features

- Specs

- Resources

Overview

Efficient post-treatment for prolonging shelf life

The KDB 120 dipping bath is used for the post-treatment of peeled or cut fruit and vegetables. The water mixed with the appropriate additives ensures a prolonged shelf life of the treated products. The machine enables resource-saving and reliable treatment of the products due to the low, adjustable filling quantity and the adjustable retention time.

The dipping bath is filled with the peeled or cut product by means of the feeding hopper. The filling process can be automated using an optional ascending conveyor belt.

The product is transported through the filled dipping tank and additionally sprayed from above so that floating products are also reliably treated. Subsequently, an optional pre-drying process (blower) takes place via the discharge, after which the product is transferred into containers or to an optionally available conveyor belt.

The KDB processes, for example, sliced and/or peeled apples with a retention time of 30 seconds and a capacity of up to 750 kg (1,654 lb) per hour. .

Your Benefits

- Resource-saving post-treatment using a minimal amount of water and additives

- Adjustable retention time for reliable treatment with sanitizing additives

- Adaptation to various product sizes

- Fast and easy cleaning

Highlights

Minimal consumption of water and additives thanks to an adjustable filling quantity

The function of the machine is already guaranteed when used with a minimum water quantity of only 24 liters. Depending on the amount and size of the product, the filling quantity can be infinitely adjusted. As a result, the KDB 120 enables a particularly resource-saving and thus economical post-treatment using small amounts of water and additives such as Nature Seal®, CITROCIDE® PLUS or powder dissolved in water.

Adjustable retention time for reliable post-treatment

The retention time of the product in the dipping bath can be adjusted via the speed of the cleated belt. A guaranteed retention time of 30 to 120 seconds is enabled to ensure that the products are reliably treated with the additives. This also makes the KDB suitable for disinfecting products. The open design guarantees extremely gentle treatment of the products.

Specs

| Max. Capacity | up to 750 kg (1,654 lb)/h |

| Disenfection | Wet |

| Electrical Power | Power: 2.2 kW (3 HP) Voltage: 3~400 V N/PE Frequency: 50 Hz |

| Water | Fresh water connection: 3/4 inch (GEKA coupling) Total volumes: 24 – 130 L (6.3 – 34.3 Gallons) |

| Dimensions | LxWxH: 2600 x 1500 x 1600 mm (102 x 59 x 63 in) Weight: 350 kg (771.6 lb) |

Industries

Vegetables