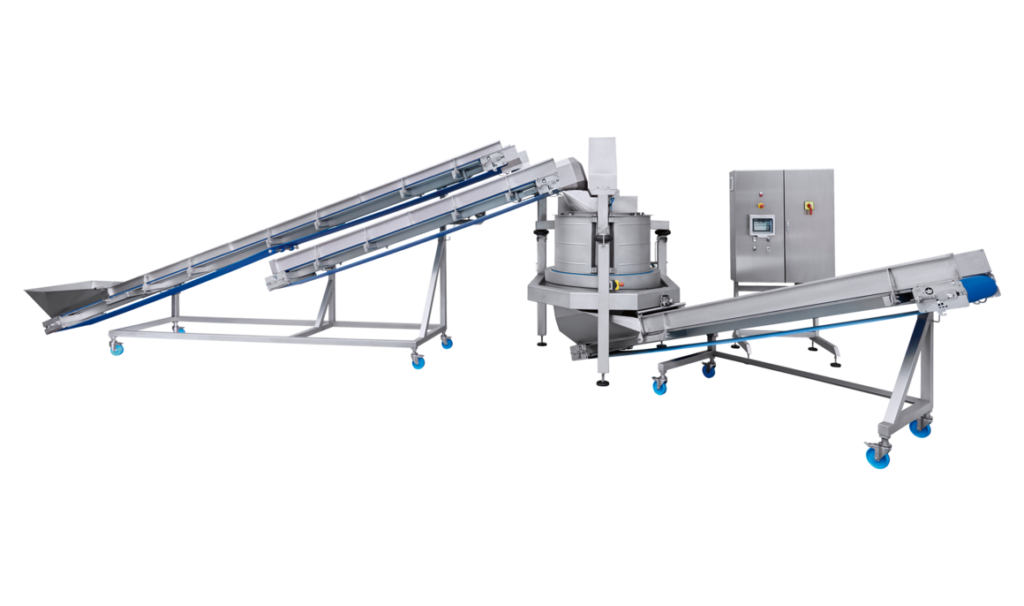

K650 drying system

Drying

By means of a large-volume centrifuge with a diameter of 650 mm (25.6″), the fully automatic, continuously operating unit is used to dry cut lettuce and whole leaves as well as cut fruit and vegetables.

up to 2,800 kg (6,170 lb)/h max. capacity

- Features

- Specs

- Resources

Overview

Dries lettuce, fruit and vegetables fully automatically, efficiently and hygienically: up to 2,800 kg (6,170 lb) of product per hour

The K650 is a fully automatic drying system for lettuce, fruit and vegetables and is designed for operation in continuous processing lines.

The product leaves the washing unit and is deposited on the infeed buffer conveyor. Due to the buffer conveyor, the K650 processes the product continuously, although the centrifuge itself dries in batches. As soon as the centrifuge with a 650 mm (25.6″)-diameter drum is full, the buffer conveyor runs in reverse mode until there is space in the centrifuge. With an optional volume control, the infed product quantity can be optimized. At the end of the drying cycle, the spinning speed is reduced and the product is gently forwarded to the discharge belt by a single blowing-off procedure. It is timed in such a way that the product flow is as even as possible. After drying, the product is transferred either into containers or onto the infeed belt of an automatic weighing or packaging machine. Without product, the unit automatically switches to energy-saving mode.

The K650 is supplied as a “Plug & Play” & version, meaning that only the cables of the individual components need to be connected in the switch cabinet to make the machine ready for operation. The switch cabinet is a free-standing unit and has a 10 m (32.8 ft) cable. The system is equipped with a TOSI-BOX for remote maintenance as standard. Optionally, the control unit can be upgraded with SMART functions.

For higher capacities up to 5,000 kg (11,000lb)/h, the upgraded K850 drying system is suitable.

Your Benefits

- Continuous dewatering: designed for large processing lines

- High drying performance, for example dewatering lettuce down to a residual moisture level of 3 %

- Ensures easy, safe operation

- Processing is extremely gentle – ideal even for sensitive products

- Various parameters enable flexible adjustment to different products

- A compact, open design enables optimal hygiene and a low space requirement

Highlights

Compact design for a low space requirement

A total of eight different installation options (infeed from two directions and discharge in five directions) are possible for the K650. The system can therefore be flexibly integrated into existing systems in an extremely space-saving manner. With the infeed and discharge conveyors, it has a space requirement of 7,500 x 4,000 x 2,400 mm to 9,600 x 3,000 x 2,400 mm (295.3 x 157.5 x 94.5″ up to 378 x 118.1 x 94.5″) (LxWxH) during processing. The cleaning process requires 9,800 x 3,000 x 3,000 mm (385.8 x 118.1 x 118.1″) (LxWxH). The unit has been designed paying special attention to safety and does not require a safety zone or protective guards that would require a great deal of space and disturb working and cleaning procedures.

Simple, effective cleaning

The open and hygienic design ensures easy cleaning and maintenance. The system can be cleaned particularly quickly due to two optional cleaning modes, which adjust the speed of the belts and the machine. The cleaning mode when changing products is set using a key-operated switch. In the cleaning mode following the end of a shift, the machine runs until it has been completely pre-cleaned with water and sprayed with a cleaning agent. The cleaning mode is then switched off and the K650 and/or the belts are cleaned. The belts are mobile and easy to remove.

Flexible settings for a perfect result

In operation, a differentiation has to be made between two users: production and service. They have different access data to prevent settings from being accidentally changed. To ensure processing efficiency and the quality of the end product, various parameters can be set – depending on the consistency, shape and size of the product. The programs can be entered, changed and saved very easily using a seven-inch touch panel. Important parameters include the spinning speed and duration, as well as a right-left run mode for large-leaved products. Some parameters are automated, including the speed of the infeed and discharge conveyors, to make the system clearly structured and easy to operate.

Specs

| Max. Capacity | up to 2,800 kg (6,170 lb)/h |

| Loading Type | Continuous |

| Electrical Power | Power: 17 kW (22.8 HP) Voltage: 3~400 V N/PE Frequency: 50 Hz |

| Air | Working pressure: 2 x 6 bar |

| Dimensions | L x W x H: 7500 x 4000 x 2400 mm up to 9600 x 3000 x 2400 mm (295.3 x 157.5 x 94.5″ up to 378 x 118.1 x 94.5″) (depending on the installation option) Weight: 1500 kg (3300 lb) Infeed/placement height: 728 mm (28.7″) Outfeed/deliver height: 1000 mm (39.4″) |

| Miscellaneous | kg (lb) per batch: 40 / 28 kg (88.2 / 61.7″) (with / without volume control) Spin speed: max. 750 RPM Spin time: 5 – 30 sec. Total cycle: 30 – 65 sec. Total volumes: 90 I |

Industries

Vegetables

Fruit

Salads