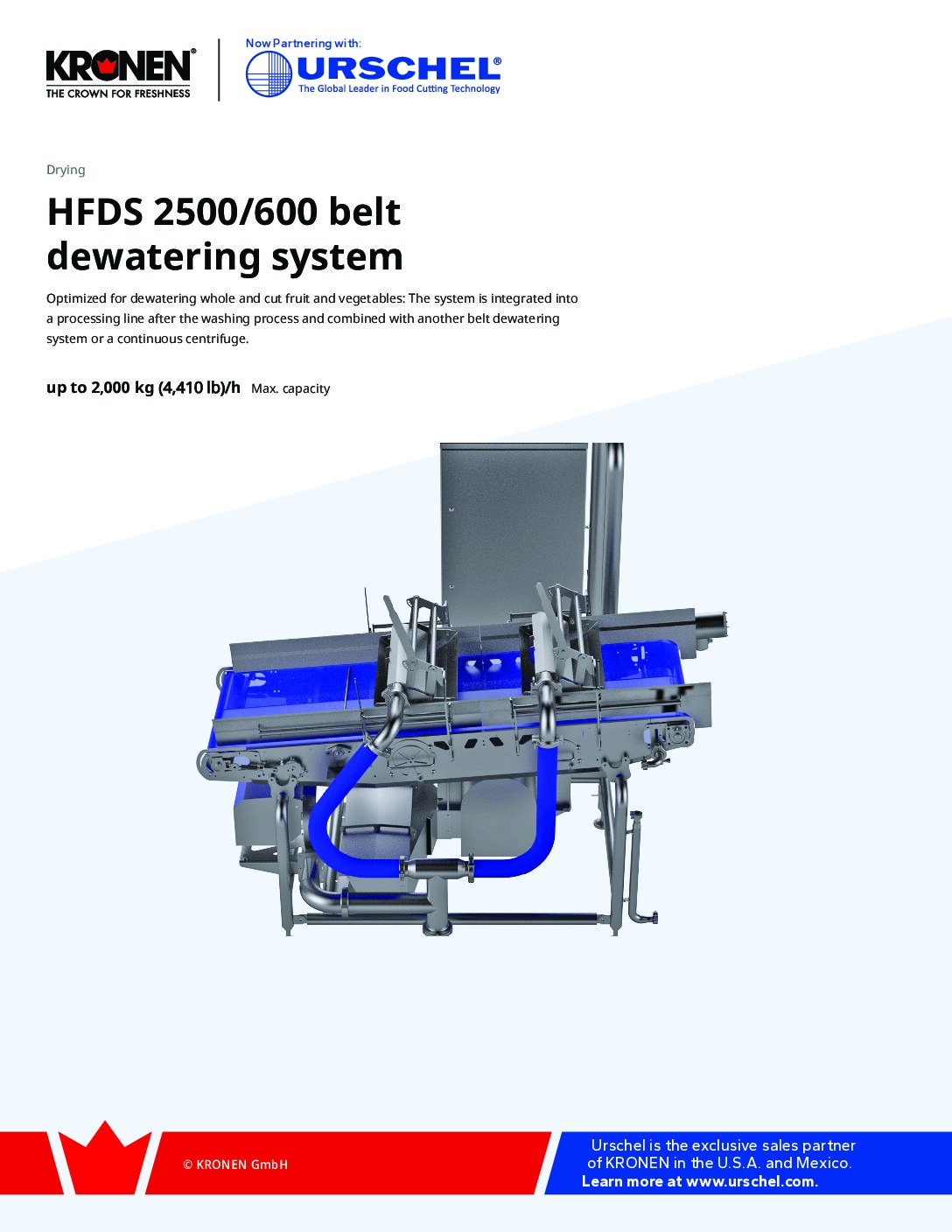

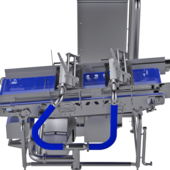

HFDS 2500/600 belt dewatering system

Drying

Optimized for dewatering whole and cut fruit and vegetables: The system is integrated into a processing line after the washing process and combined with another belt dewatering system or a continuous centrifuge.

up to 2,000 kg (4,410 lb)/h max. capacity

- Features

- Specs

- Resources

Overview

Ideal for fruit and vegetables: dewatering up to 2,000 kilograms (4,410 lb) of whole or cut products per hour

The HFDS 2500/600 from KRONEN’s partner company Hitec Food Systems is a dewatering system accommodated in a line after the washing process and prior to packaging. The system is particularly suitable for whole products such as potatoes, snack cucumbers, apples or sultanas, as well as for sliced products such as apple rings, for example. It is also suitable for the preliminary dewatering of cut lettuce and other leafy products.

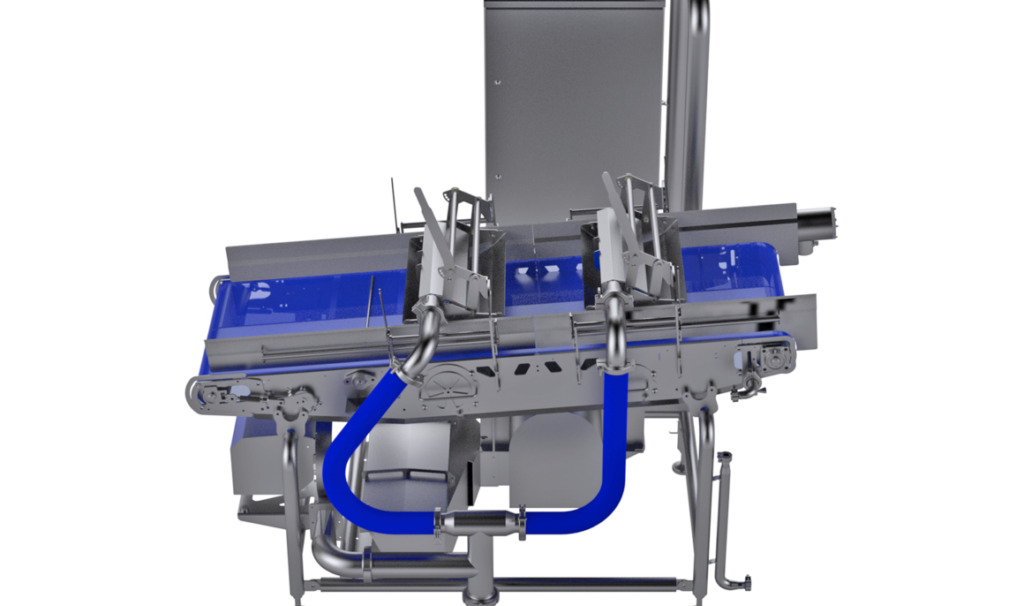

The product falls from an infeed belt onto the entry belt and is dewatered at two stations. The combination of air knives and suction fans removes the water adhering to the product particularly effectively. A knocking station positioned in front of each blower unit distributes the product evenly across the entire width of the belt to ensure an optimum dewatering result. A noise reduction box reduces the noise level of the suction fans and the air guide inside the box separates water from the airflow in a controlled manner.

The machine achieves a product with a residual moisture of approximately 6 to 8 percent without excessive mechanical stress. If the HFDS 2500/600 is used for the preliminary dewatering of lettuce, an additional dewatering step, e.g. with the BDS 3000/800 belt dewatering system or with a continuous centrifuge such as the K650, is installed as an upstream or downstream unit.

Your Benefits

- Continuous dewatering: designed for large processing lines

- Gentle drying of whole and cut products

- Combination of swirling and suction removes surface water particularly effectively

Highlights

Flexible settings and easy cleaning

The air jet intensity and belt speed can be controlled by means of a frequency converter. The air knives are height-adjustable in several steps and can therefore be adjusted to match the size of the product. The suction power can be varied by means of an adjustable air supply opening. The mesh grid belt is available in different sizes (1000, 2000 and 3000 μm). The side guides on the belt can be folded down to make cleaning easier. The open construction made of stainless steel and with easy access to the pipework also guarantees an optimal hygienic design.

Specs

| Max. Capacity | up to 2,000 kg (4,410 lb) (The capacity depends on factors such as the product.) |

| Loading type | Continuous |

| Electrical power | Power: 15 kW (20.1 HP) Voltage: 3~400 V N/PE Frequency: 50 Hz |

| Dimensions | LxWxH: 2550 x 1545 x 1900 mm (+/- 50 mm) (100.4 x 61.2 x 74.8″) (+/- 2″) Weight: 950 kg (2100 lb) Infeed/placement height: 1040 mm (+/- 50 mm) (44.9″) (+/- 2″) Outfeed/delivery height: 1220 mm (+/- 50 mm) (48″) (+/- 2″) |

| Miscellaneous | Belt width: 600 mm (23.6″) Height of raw product: max 150 mm (5.9″) |

Industries

Vegetables

Fruit