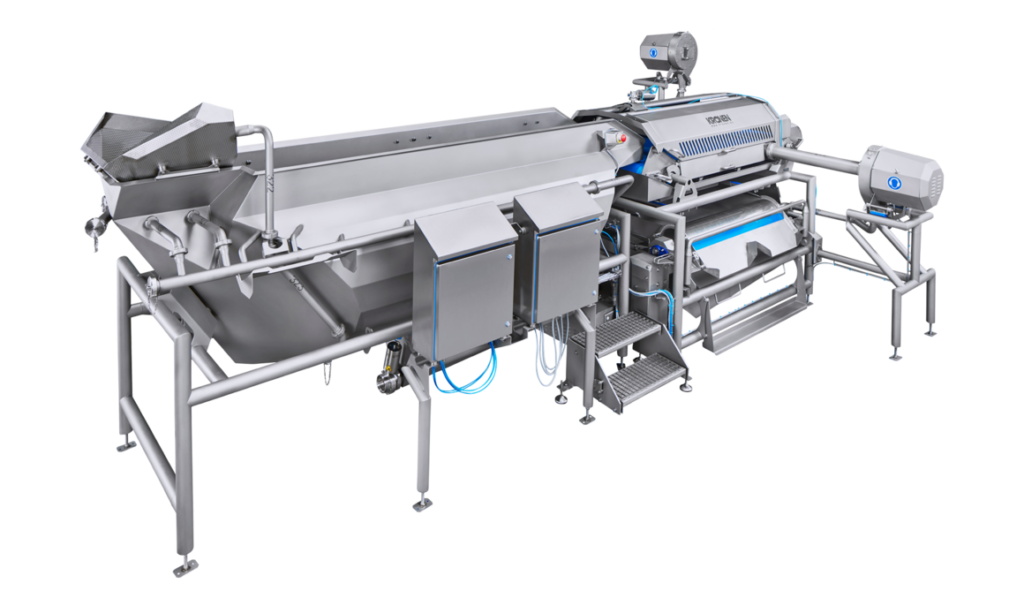

GEWA XL washing machine with belt outfeed

Disinfection, Washing, Mixing

The high-performance washing machine is used for the continuous pre-washing, washing, disinfection and treatment of lettuce, vegetables, herbs and fruit, among others. It sets new standards in terms of hygienic design and cleaning. The GEWA XL is positioned in the processing line upstream of a drying system such as the K850 and can be combined with a pre-washing machine such as the GEWA AF.

5,000 kg (11,000 lb)/h Max. capacity

- Features

- Specs

- Resources

Overview

Wash very large quantities with the latest hygiene standards: up to 5,000 kg (11,000 lb) of product per hour

The further developed GEWA XL is a high-performance washing machine suitable for use in industrial applications and for washing very large quantities of lettuce, vegetables and fruit. The capacity depends on the product: for example, up to 1,500 kg (3,300 lb) of baby leaf and up to 5,000 kg (11,000 lb) of iceberg lettuce can be processed per hour. The standard equipment of the GEWA XL includes a highly effective, gentle emergence module, the XL wash tank with the HELICAL system, a lateral fine particle removal drum and an optional insect removal module with an extended contact area.

Both floating and sinking products are conveyed through the wash tank by the HELICAL washing system in a spiral movement. At the end of the wash tank, the product and the water are transported to a belt outfeed by means of an overflow and sprayed with a fresh water shower. The water flows through a lateral fine particle drum with a slotted strainer into the pump tank, from which it is pumped back into the wash tank. Finally, the products are already pre-dewatered for further processing with a suction blower, and an air knife system on the outfeed belt ensures an effective and gentle transfer.

The GEWA XL is designed for use in a large production line and can be combined, for example, with the GEWA AF pre-washing machine and the K850 drying system.

Versatile application options:

- Lettuce (e.g. baby leaf, iceberg): cut and whole leaves

- Salad mixes with non-floating products, such as carrot sticks

- Vegetables: whole or cut

- Herbs (e.g. parsley, chives): loose

- Fruit (e.g. mango): whole or cut

- Other leafy products (e.g. spinach), tuber products, pulses and mushrooms, as well as seaweed or kelp

As a result, GEWA ensures an undamaged, optimally cleaned product that, if necessary, has been disinfected with a washing additive. In addition, the product can be efficiently mixed (e.g. mixed salads) and cooled down by the washing process.

Your Benefits

- Very high capacities of up to 5,000 kg (11,000 lb)/h possible in the XL wash tank

- Effective and gentle washing due to the HELICAL washing system

- The HELICAL washing system makes the machine versatile and space-saving

- Reduced water consumption with perfect washing results

- Optimal separation of foreign objects, for example sand, stones and insects

- Washing, disinfection, mixing and rinsing possible in one machine

Highlights

Water chute for gentle product infeed

The submergence module places the light and sensitive product underwater without additional mechanical stress. The product falls onto a water chute where it is surrounded by water from all sides. Safely packed in the water, the leaves slide into the wash tank. No mechanical or even powered installations are necessary to submerge the product.

Highly effective, gentle HELICAL washing system

KRONEN’s HELICAL washing system ensures that the product travels along a spiral-shaped route in the wash tank that is up to ten times longer than the wash tank. Due to the ideal distribution, the product is loosened up and constantly rinsed completely during the cleaning process. Products are therefore washed thoroughly and gently, water consumption is considerably reduced, and the machine is ideal for a wide range of applications.

Sand trap sedimentation unit

The sand trap integrated into the wash tank separates the loosened heavy dirt (e.g. small stones) and sand from the product flow. Dirt and sand settle in the sand trap at the bottom of the wash tank and are not discharged from the wash tank with the product.

Lateral fine particle removal drum

The lateral fine particle drum with a slotted strainer opening of 0.5 mm (.020″) filters particles out of the circulating wash water. It enables continuous operation without blocking the filter above the pump tank and protects the pumps. This is particularly important for products that foam and contain many small particles.

The latest hygiene standards

When it comes to hygienic design, the GEWA XL sets new standards. It can be completely disassembled, ensuring access to the entire machine for easy cleaning and maintenance. In order to clean the pipe system without needing to disassemble it and to ensure the lowest possible water consumption, a clean-n-place system can also be integrated as an option. All pipes, the pump casing, the wash and pump tanks and the covers and switch cabinet are made from AISI 304 stainless steel.

Specs

| Max. Capacity | 500-5,000 kg (1,100-11,000 lb)/h (The capacity depends on factors such as the product.) |

| Disinfection | Wet disinfection |

| Electrical power | Power: 19 kW (25.5 HP) Voltage: 3~400 V N/PE Frequency: 50 Hz |

| Water | Fresh water connection: 3/4 inch (GEKA coupling) Water drainage: 2 x 2″ Total volumes: 2,600 l |

| Air | Working pressure: 6 bar |

| Dimensions | LxWxH: 5644 x 2487 x 1921 mm / (222.2 x 97.9 x 75.6″) Weight: 1580 kg (3,485 lb) Infeed/placement height: 1790 mm (70.5″) Outfeed/delivery height: 973 mm (38.3″) |

Industries

Vegetables

Fruit