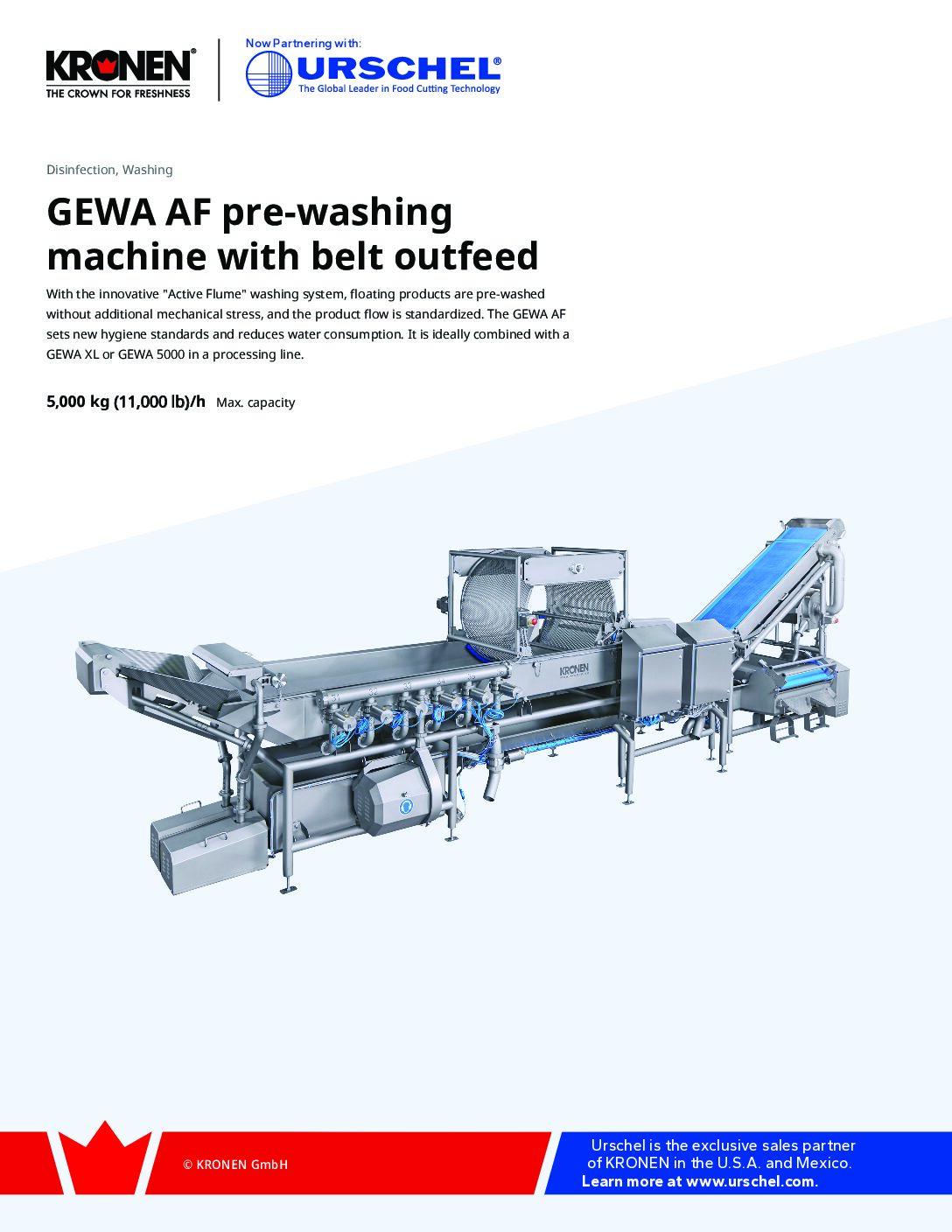

GEWA AF pre-washing machine with belt outfeed

Disinfection, Washing

With the innovative “Active Flume” washing system, floating products are pre-washed without additional mechanical stress, and the product flow is standardized. The GEWA AF sets new hygiene standards and reduces water consumption. It is ideally combined with a GEWA XL or GEWA 5000 in a processing line.

5,000 kg (11,000 lb)/h Max. capacity

- Features

- Specs

- Resources

Overview

The latest hygiene standards and reduced water consumption: pre-washing of up to 5,000 kg (11,000 lb) of product per hour

The GEWA AF is used as a pre-washer to remove coarse dirt, sand and stones from light, sensitive products. Due to its method of operation, it is also used to absorb production peaks and therefore make the product flow more continuous. The GEWA AF stands in a processing line downstream from a cutting machine or a weighing system. It takes over the first washing step, which is normally followed by at least one further washing step with a suitable HELICAL washing machine such as the GEWA XL or the GEWA 5000 or GEWA 4000. The capacity depends on the product; for example, 400 to 1,500 kg (881.8 to 3306.9 lb) of baby leaf, up to 3,000 kg (6613.9 lb) of iceberg lettuce or up to 1,000 kg (2204.6 lb) of baby spinach can be processed per hour.

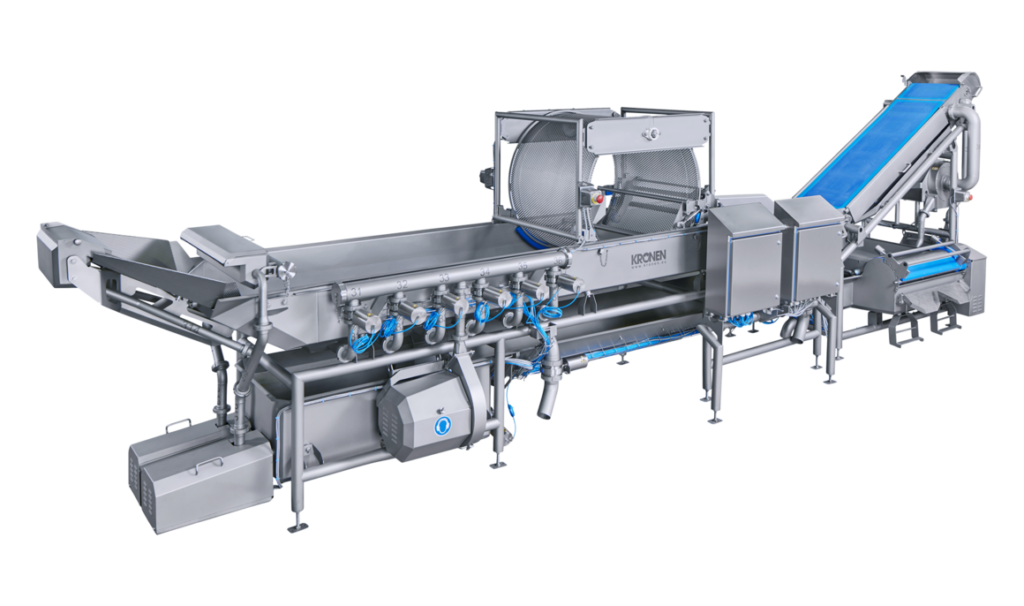

The standard equipment of the GEWA AF includes a highly effective, gentle submergence module, an air module for separating out sand and stones and for loosening contamination, a module with an insect removal drum and a settling module in which sand and stones sink and are regularly flushed out of the machine by means of the sand trap and an automatic valve, while the cleaned product is discharged via the outfeed belt. The side fine particle removal drum continuously filters the water as it runs into the filter tank.

The pre-washer is designed for lettuce, baby leaf and leafy vegetables (whole or cut) as well as floating cut vegetables, such as cabbage and cauliflower or broccoli florets.

The other GEWA washing machines are suitable for non-floating products.

Your Benefits

- Gentle pre-washing of large quantities of floating product

- Low water volume compared to capacity – thus extremely water-saving

- Modular design and therefore individually adjustable

- Special air section with an integrated sand trap for effective separation of sand, dirt and stones

- Latest hygiene standards and optimal cleaning, e.g. by a clean-in-place system

- Pre-washing, disinfection and rinsing, as well as production flow standardized in one machine

Highlights

Water chute for gentle product infeed

The submergence module places the light and sensitive product underwater without additional mechanical stress. The product falls onto a water chute where it is surrounded by water from all sides. Safely packed in the water, the leaves slide into the wash tank. No mechanical or even powered installations are necessary to submerge the product.

Air section with integrated sand trap

Six independently controlled air distribution boxes supply the entire section with air. The air bubbles bring movement into the tank and create currents that submerge the product. The leaves are further separated from sand, dirt and other foreign objects. A sand trap is integrated into this module, which catches the sand loosened from the leaves. Here, too, a special focus was placed on hygiene and easy cleaning.

Insect and fine particle removal system with an extended area

The insect removal system in the GEWA AF has a particularly large cross section and an extended contact area to separate the insects floating on the surface from the leafy product. The insect drum can be easily swiveled out of the wash tank, for example for cleaning. It also has an open design for easy access. At the same time, operational safety is guaranteed.

Process large quantities with a low water volume

The water-to-product ratio in the GEWA AF is only four liters of water to one liter of product. This ratio is ideal for pre-washing: cell sap, sand and dirt can be removed. The total wash tank capacity of the GEWA AF in the standard version is 1,400 liters of water. This makes the machine particularly water-saving in relation to its capacity.

The latest hygiene standards

When it comes to hygienic design, the GEWA AF sets new standards. For quick and easy cleaning, everything inside the wash tank has an open design and there are no air pipes. The GEWA AF pipes can also be completely disassembled. In order to clean the pipe system without needing to disassemble it and to ensure the lowest possible water consumption, a clean-in-place system can be integrated as an option.

Modular design for flexible use

Thanks to its modular design, the GEWA AF can be used flexibly. Depending on the product and requirements, various combinations are possible and modules can be added, replaced and reproduced. For example, two air modules can be combined (see fig.). The machine is also available in a mirrored version. As a pre-washing machine, it also comes as a shorter version without an insect removal drum.

Specs

| Max. Capacity | 500-5,000 kg (1,100-11,000 lb)/h (The capacity depends on factors such as the product.) |

| Disinfection | Wet disinfection |

| Electrical power | Power: 16 kW (21.5 HP) (V outfeed / B outfeed) Voltage: 3~400 V N/PE Frequency: 50/60 Hz |

| Water | Fresh water connection: 3/4 inch (GEKA coupling) Water drainage: 3″ Total volumes: 1,400 l |

| Air | Working pressure: 6 bar Air consumption: 58 NL/min. |

| Dimensions | LxWxH: 7722 x 1996 x 2242 mm / (304 x 78.6 x 88.3″) Weight: 1850 kg (4080 lb) Infeed/placement height: 1540 mm (60.7″) Outfeed/delivery height: 1,861 mm (73.3″) |

Industries

Vegetables