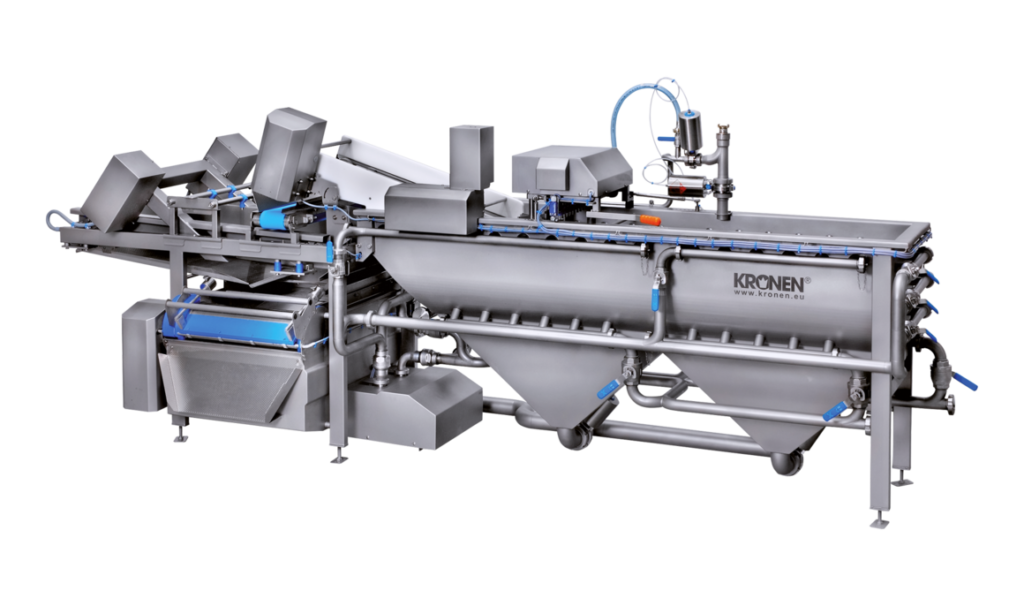

GEWA 3850V PLUS washing machine for peppers

Disinfection, Preparing, Washing

Specially designed for sorting, trimming and washing uncored cut peppers and other products that can be sorted according to their flotation characteristics – with an ingenious separation process and effective fine particle separation.

1,200 kg (2,645 lb)/h max. capacity

- Features

- Specs

- Resources

Overview

Specially designed for the effective sorting and washing of up to 1,200 kg (2,645 lb) of product per hour

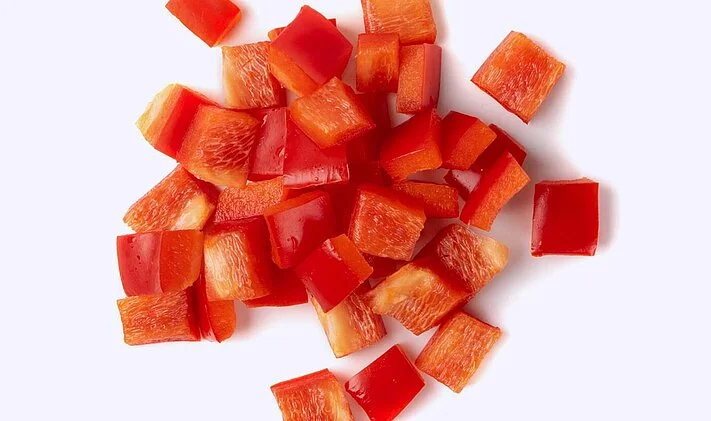

The GEWA 3850V PLUS is specially designed for washing and sorting diced peppers or peppers cut into strips. In this process, the complete cut pepper with stalk and seeds is processed. During the washing process and by means of a unique, ingenious system of different water flows, the good product is separated from the waste in one single step. This saves the extra steps and effort of preparing or sorting.

The cut product is brought into the wash tank either automatically via an infeed belt or manually. The specially adjusted flow behavior in the wash tank ensures that the good product is separated from the waste and efficiently washed and discharged at the same time. With the lateral fine particle removal drum and two sand trap funnels, which are included as standard on the GEWA 3850T PLUS, dirt and fine particles can be perfectly separated out. In addition, the fresh water supply and emptying of the washing machine are also controlled centrally.

At the end of the wash tank, the good product and the water are transported to a vibration outfeed by means of an overflow and sprayed with a fresh water shower. The water flows through a strainer into the pump tank, from which it is pumped back into the wash tank and used again. The flow rate and movement of the water in the wash tank can be adjusted to suit different products.

Your Benefits

- Washing and sorting takes place in one step – personnel and space requirements are therefore reduced

- Effective and gentle washing due to the HELICAL washing system

- Reduced water consumption with perfect washing results due to the HELICAL washing system

- Continuous washing process with automatic filling, no operating personnel required

- Trimming, sorting, washing, disinfection and rinsing possible in one machine

- Can be used as a universal HELICAL washing machine for versatile applications

Highlights

Flotation separation process

This process enables sorting during the washing process. It can be used for peppers that are diced or cut into strips and for other products that can be sorted according to their flotation characteristics. The stem and immature white parts float on the surface of the water and are discharged via a special conveyor belt with a stainless steel link belt. Heavy parts (cores) sink to the bottom of the tank and are channeled out via the sand trap. The good product is distributed in the remaining water volume of the washing machine and is discharged via the vibration outfeed for further processing.

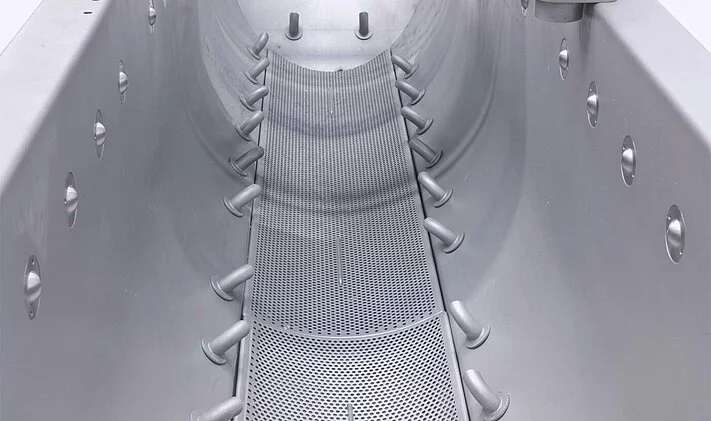

Highly effective, gentle HELICAL washing system

KRONEN’s HELICAL washing system ensures that the product travels along a spiral-shaped route in the wash tank that is up to ten times longer than the wash tank. Due to the ideal distribution, the product is loosened up and constantly rinsed completely during the cleaning process. Products are therefore washed thoroughly and gently, water consumption is considerably reduced, and the machine is ideal for a wide range of applications.

Sand trap sedimentation unit

The sand trap integrated into the wash tank separates the loosened heavy dirt (e.g. small stones) and sand from the product flow. Dirt and sand settle in the sand trap at the bottom of the wash tank and are not discharged from the wash tank with the product. (Fig. GEWA 3800 PLUS)

Sand trap funnel for increased volume

A sand trap funnel is necessary for washing heavily soiled products or for separating pepper seeds in the case of cut peppers or non-germinated seeds in the case of sprouts. It can accommodate a volume of 49 l, or 98 l in the case of the GEWA 3850T PLUS. (Fig. GEWA 4000)

Lateral fine particle removal drum

The lateral fine particle removal drum with a slotted strainer opening of 0.5 mm filters particles out of the circulating wash water. It enables continuous operation without blocking the filter above the pump tank and protects the pumps. This is particularly important for products that foam and contain many small particles. (Fig. GEWA AF)

Water management system (WMS)

The WMS enables centrally controlled filling and emptying of the washing machine. During operation, an additional level sensor automatically regulates the water level in the washing machine. If the water level drops too low, the pneumatic infeed valves are automatically opened and fresh water is provided. (Fig. GEWA 4000)

Ideal accessibility for cleaning and maintenance

All areas are easily accessible for easy cleaning and maintenance. All pipes, the pump casing, the wash and pump tanks and the covers and switch cabinet are made from AISI 304 stainless steel. All in all, the washing machines impress users with their optimal hygienic design. In the PLUS models with vibration outfeed, there are no screws whatsoever in the product area. (Fig. HEWA 4000)

Specs

| Max. Capacity | 200 – 1,200 kg (440 – 2,645 lb)/h (The capacity depends on factors such as the product.) |

| Disinfection | Wet disinfection |

| Electrical power | Power: 7.9 kW (10.6 HP) (V outfeed / B outfeed) Voltage: 3~400 V N/PE Frequency: 50 Hz |

| Water | Fresh water connection: 3/4 inch (GEKA coupling) Water drainage: 2 x 2″ Total volumes: 814 l |

| Dimensions | LxWxH: 4452 x 1640 x 1829 mm (175.3 x 64.6 x 72″) Weight: 560 kg (1235 lb) Infeed/placement height: 1232 mm (48.5″) Outfeed/delivery height: 925 (36.4″) |

| Note | The data indicated are standard information. In addition, adaptation to other supply networks (e.g. 230V/60 Hz) is optionally possible (except for manual and pneumatic machines). Subject to changes. |

Industries