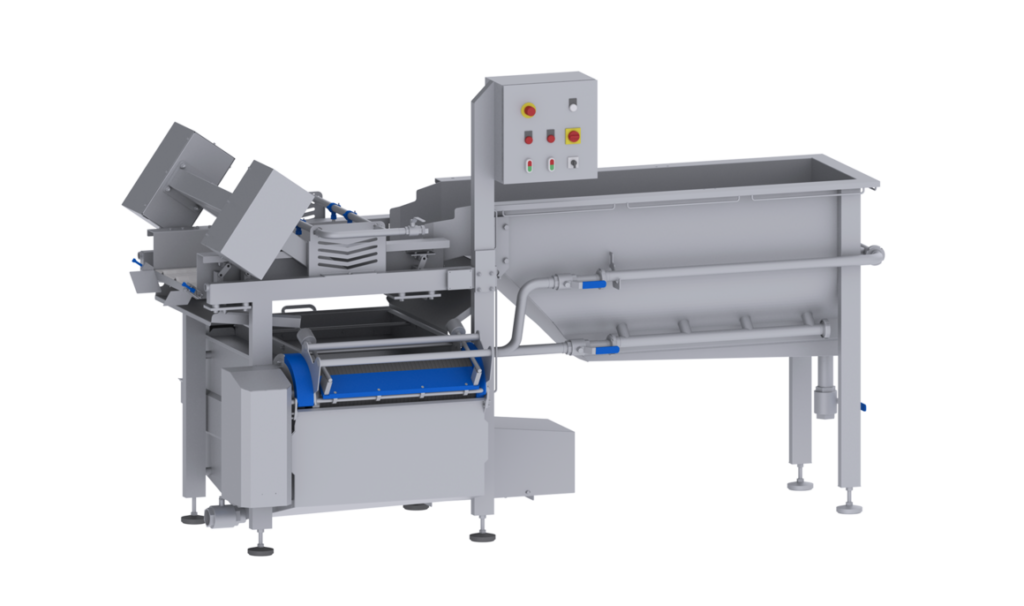

GEWA 2600 PLUS washing machine with vibration or belt outfeed

Disinfection, Washing, Mixing

A universal washing machine for the continuous pre-washing, washing, disinfection and treatment of both cut and whole lettuce, vegetables, herbs and fruit, among others.

600 kg (1,300 lb)/h max. capacity

- Features

- Specs

- Resources

Overview

Effective, gentle and economical washing of up to 600 kg (1,300 lb) per hour

The GEWA 2600 PLUS is used for pre-washing, washing, disinfecting, mixing, treating and rinsing lettuce, vegetables and fruit. It can be used flexibly and is usually positioned downstream of a cutting machine between the low-care and high-care area.

The wash tank is filled either automatically via an infeed belt or manually. Both floating and sinking products are conveyed through the wash tank by the HELICAL washing system in a spiral movement. The flow rate and movement of the water in the wash tank can be adjusted to suit different products. At the end of the wash tank, the product and the water are transported to a vibration or belt outfeed by means of an overflow and sprayed with a fresh water shower. The water flows through a strainer into the pump tank, from which it it pumped back into the wash tank and used again.

Versatile application options:

- Lettuce (e.g. baby leaf, iceberg): cut and whole leaves

- Vegetables: cut and whole

- Herbs (e.g. parsley, chives): loose and in bunches

- Fruit (e.g. pineapple, melon): cut and whole

- Other leafy products (e.g. spinach), tuber products, pulses and mushrooms, as well as seaweed or kelp

As a result, the GEWA ensures an undamaged, optimally cleaned product that, if necessary, has been disinfected with a washing additive. In addition, the product can be efficiently mixed (e.g. mixed salads) and cooled down by the washing process.

Your Benefits

- Effective and gentle washing due to the HELICAL washing system

- The HELICAL washing system makes the machine versatile and space-saving

- Reduced water consumption with perfect washing results

- Optimal separation of foreign objects, for example sand, stones and insects

- Continuous washing process – with automatic filling, no operating personnel required

- Washing, disinfection, mixing and rinsing possible in just one machine

Highlights

Vibration or belt outfeed

The washing machines are available with vibration or belt outfeed. The chosen outfeed depends on the specific requirements. The vibration outfeed ensures preliminary dewatering of the product, sorts out small particles and is easier to clean. Filter strainers with hole sizes of 2, 5, 8 or 10 mm (0.08, 0.20, 0.31, 0.39″), for example, are available, enabling product-specific adaptations. In addition to the standard version, a version with an outfeed extended by 500 mm (19.7″) (GEWA PLUS) or 400 mm (15.7″) (GEWA ECO) is available. A belt outfeed may enable a higher capacity and is more suitable for individual products. What’s more, the machine does not necessarily need to be raised in case of a wash cascade function. (Fig. GEWA 3800V PLUS)

Highly effective, gentle HELICAL washing system

KRONEN’s HELICAL washing system ensures that the product travels along a spiral-shaped route in the wash tank that is up to ten times longer than the wash tank. Due to the ideal distribution, the product is loosened up and constantly rinsed completely during the cleaning process. Products are therefore washed thoroughly and gently, water consumption is considerably reduced, and the machine is ideal for a wide range of applications.

Sand trap sedimentation unit

The sand trap integrated into the wash tank separates the loosened heavy dirt (e.g. small stones) and sand from the product flow. Dirt and sand settle in the sand trap at the bottom of the wash tank and are not discharged from the wash tank with the product. (Fig. GEWA 3800 PLUS)

Ideal accessibility for cleaning and maintenance

All areas are easily accessible for easy cleaning and maintenance. All pipes, the pump casing, the wash and pump tanks and the covers and switch cabinet are made from AISI 304 stainless steel. All in all, the washing machines impress users with their optimal hygienic design. In the PLUS models with vibration outfeed, there are no screws whatsoever in the product area. (Fig. HEWA 4000)

Compact and modular design

Thanks to the HELICAL washing system, GEWA washing machines are particularly compact. They also have a modular design, which enables the flexible adaptation of the machine to the requirements in production operations. For example, it is possible to retrofit the air system or other options that can be quickly and easily installed as a kit.

Specs

| Max. Capacity | 50-600 kg (110-1,300 lb/h) (The capacity depends on factors such as the product.) |

| Disinfection | Wet disinfection |

| Electrical power | Power: 3.1 kW / 3.2 kW (4.2 HP / 4.3 HP) (V outfeed / B outfeed) Voltage: 3~400 V N/PE Frequency: 50 Hz |

| Water | Fresh water connection: 3/4 inch (GEKA coupling) Water drainage: 2 x 2″ Total volumes: 606 l |

| Dimensions | LxWxH: 2872 x 1382 x 1675 mm / 3211 x 1381 x 1675 mm (113 x 54 x 66″ / 126 x 54 x 66″) (V outfeed / B outfeed) Weight: 445 kg / 414 kg (981 lb / 913 lb) (V outfeed / B outfeed) Infeed/placement height: 1232 mm (48.5″) Outfeed/delivery height: 933 mm / 759 mm (36.7″ / 29.9″) (V outfeed / B outfeed) |

| Note | The data indicated are standard information. In addition, adaptation to other supply networks (e.g. 230V/60 Hz) is optionally possible (except for manual and pneumatic machines). Subject to changes. |

Industries

Vegetables

Fruit