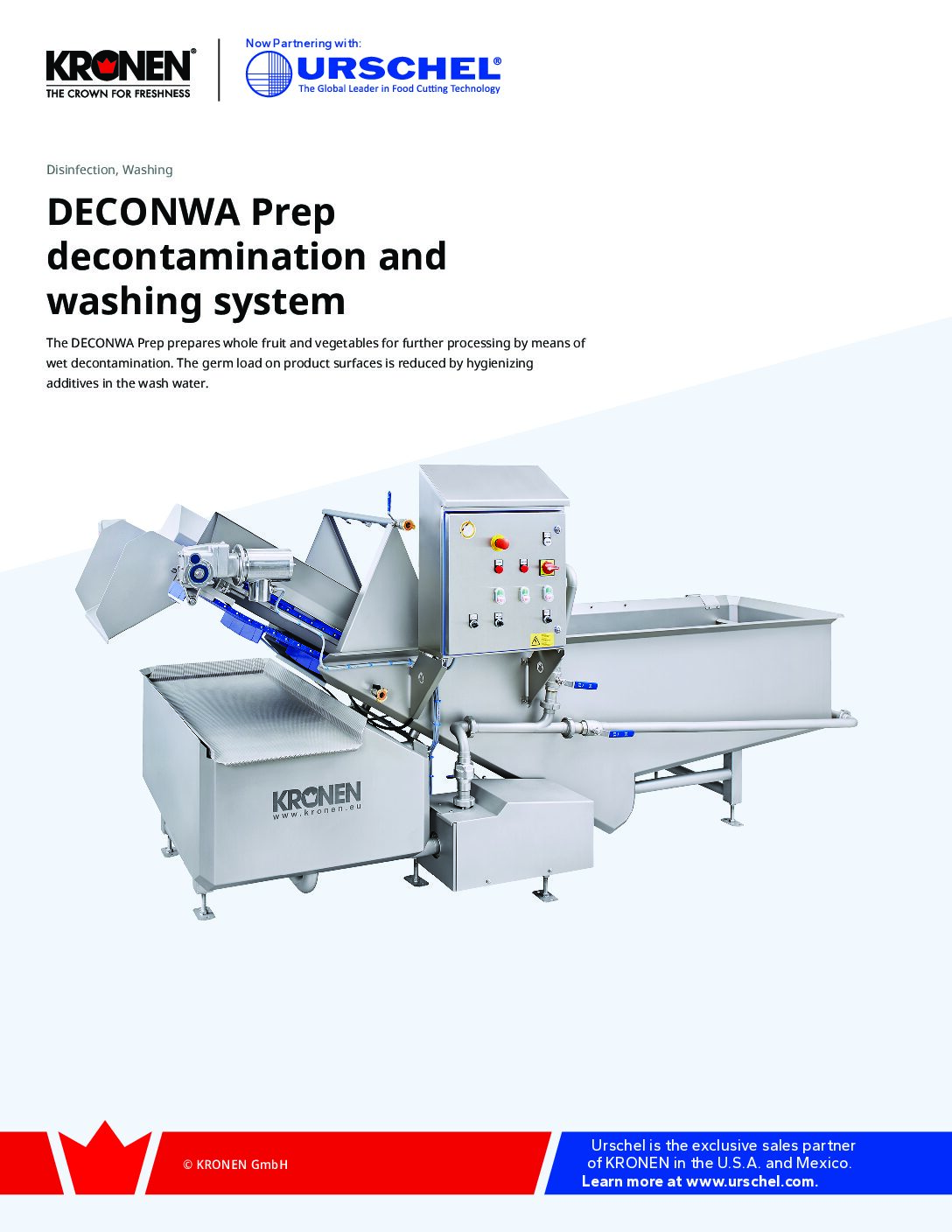

DECONWA Prep decontamination and washing system

Disinfection, Washing

The DECONWA Prep prepares whole fruit and vegetables for further processing by means of wet decontamination. The germ load on product surfaces is reduced by hygienizing additives in the wash water.

- Features

- Specs

- Resources

Overview

Decontamination of whole products with a guaranteed retention time

The DECONWA Prep is used to reduce the germ, virus and bacterial load on the surface of whole fruit and vegetables. For this purpose, hygienizing additives such as chlorine or peracetic acid are introduced into the wash water. The wet decontamination prepares the raw products for further processing. The cross-contamination of products with each other, as well as during peeling or cutting, is reduced and the shelf life is improved.

During transfer from low-care to high-care production areas, the DECONWA Prep ensures optimal hygiene right from the start of processing.

The construction of the machine is compact and has a low filling height and a small footprint. It can be adjusted to suit different products and production requirements by means of various settings and options.

The capacity depends on various factors – for example, approximately 1,000 kg (2,200 lb) of apples can be processed per hour with a cycle time of 4.5 minutes (1.5 minutes for filling, 30 seconds retention time and 2.5 minutes for discharge).

Your Benefits

- Optimal hygiene by reducing cross-contamination

- Controlled retention time in the wash tank

- Suitable for a variety of sinking and floating products with diameters from 20 to 400 mm (13/16 to 15/7″)

- Automatic product outfeed by means of a link belt

Highlights

Intelligent flow control for adjustment to sinking or floating products

The flow behavior in the wash tank is controlled via a flexible baffle plate. When floating products are processed, it is inserted into the wash tank and provides propulsion on the water surface in the wash tank so that the products there float in the direction of the outfeed belt.

The use of the baffle plate is not necessary for the washing process of heavier, sinking products. The water flow in the lower part of the wash tank transports the settled products.

High degree of safety due to separate operation of the outfeed belt

The DECONWA Prep is ideal for use as a link between low-care and high-care production areas. To ensure the safety of the employees in the spatially separated production areas, it is equipped with a separate control of the outfeed conveyor, which can be used as necessary.

Rain shower with flexible placement

The integrated rain shower ensures that even light products floating on the surface come into full contact with the wash water and the hygienizing additives contained. A sliding strainer is placed underneath the water supply, enabling adjustment to suit different product sizes. The staggered arrangement of the holes in the strainer guarantees complete sprinkling of the wash tank area below.

Fresh water shower at the product outfeed

The fresh water shower above the product discharge conveyor ensures that any possible residues of hygienizing additives are sprayed off the washed products. At the same time, the wash tank is constantly refilled.

Easy cleaning

The provided suspension elements for removable parts such as the baffle plate, the rain shower strainer and the fresh water shower make the washing machine easier to clean by increasing accessibility to the inside of the machine.

Specs

| Disinfection | Wet disinfection |

| Electrical power | Power: 2.9 kW (3.9 HP) Voltage: 3~400 V N/PE Frequency: 50 Hz |

| Water | Fresh water connection: 2 x 3/4 inch (GEKA coupling) Water drainage: 2 x 2″ Total volumes: 885 l |

| Dimensions | LxWxH: 3399 x 1178 x 1559 mm (133.8 x 46.4 x 61.4″) Weight: 390 kg (859.8 lb) Infeed/placement height: 887 mm (34.9″) Outfeed/delivery height: 979 mm (38.5″) Belt width: 550 mm (21.7″) |

Industries

Vegetables

Fruit

Salads