Convenience Avocado Line

Peeling, Preparing, Cutting, Conveying

A semi-automatic system for pitting, halving and peeling avocado and various types of fruit: for more efficiency, very gentle processing and high product quality.

Up to 4,800 pieces/hour max. capacity.

- Features

- Specs

- Resources

Overview

Perfect avocados in large quantities: pitting, halving and peeling up to 4,800 pieces/hour.

The semi-automated Convenience Avocado Line is a specially developed solution for peeling, halving and pitting large quantities of avocados gently yet efficiently, making processing easier for personnel and increasing productivity per person to the maximum. The ergonomic tools prevent wrist strain during pitting and peeling. This is because the rotating movement that is necessary when processing manually with a knife or spoon would otherwise lead to injuries when processing large quantities.

The following machines or solutions are integrated into the line:

- Cutting: TONA S180K cutting machine or Tona Rapid with an infeed belt for halving avocados

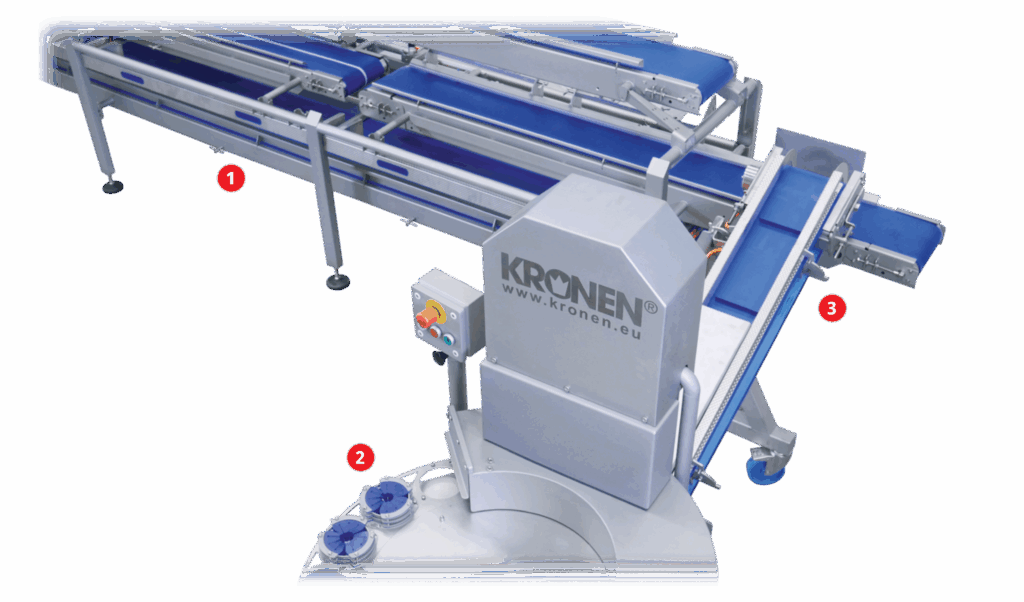

- Conveying: PLUS inclined conveyor belt

- Preparation: Processing station (in combination with the TONA S180K cutting machine, the station is designed for nine people as standard; if the Tona Rapid is integrated as an alternative, it is correspondingly larger) with several workstations and each with

- a conveyor belt, outfeed and waste belt

- specially developed tools for pitting and peeling avocados

Optionally, a GS 10-2 belt cutting machine can be added to the line to further process the avocados into cubes or slices.

Application options and capacities:

The system is designed for processing avocados but can also be adapted to process medium quantities of various other types of fruit.

Capacity with TONA S180K:

- up to 1,200 pieces/hour

- approx. 300 kg (660 lb) raw product mass/hour

- Approx. 165 kg (360 lb) finished product/hour

Capacity with Tona Rapid:

- up to 4,800 pieces/hour

- approx. 1,200 kg (2,640 lb) raw product mass/hour

- approx. 660 kg (1,450 lb) finished product/hour

The end product and waste product are automatically separated at the processing station via the outfeed and waste belt.

Your Benefits

- Semi-automatic processing for higher quantities and more efficiency in production

- Very gentle processing and very high product quality

- Integrated, among other things, is a processing table with stations specially developed for processing the delicate avocado

- Makes processing easier for personnel due to the particularly ergonomic tools

- Maximum yield ratio – the fruit flesh is fully utilized

- Optional: the avocado can be cut into cubes or slices with a cutting machine.

Highlights

Perfect avocados in large quantities

With the system, large quantities of avocados can be processed in the shortest possible time and with maximum care. The delicate fruit is turned into a visually appealing product comparable to the result of manual processing. The surface of the fruit flesh is even smoother when peeling with the peeling tool than when peeling with a knife, spoon or similar conventional tools.

Simple, ergonomic operation

Gentle, safe and at the same time flexible, effective processing is guaranteed at all stations: adapted and optimized with regard to the ergonomic requirements of the operating personnel. A user-friendly interface and the clearly arranged control panel enable quick and easy operation. The tools are flexibly adjustable in height (between 900–980 mm). Like the cutting inserts, they can be changed easily and in a short time.

Complete solutions from a single sources

KRONEN is a reliable partner, even when it comes to implementing automated processing lines. With a high level of planning and consulting expertise, the company implements the right solution for every customer requirement. KRONEN offers complete lines from a single source and integrates suitable machines from partners as required.

Maximum yield

The pitting and peeling process is designed to make full use of the fruit flesh, leaving only the minimum amount of waste. For avocado fruit, the yield ratio is approx. 55 percent.

Specs

| Max. Capacity | up to 4,800 pieces/hour (Depends on factors such as the product.) |

| Operator | Semi-automatic |

| Peeling | Knife-peeling |

- Preparation table with several workstations and a conveyor belt, outfeed and waste belt

- TONA S180K multifunctional cutting machine (max. 1,200 pieces/hour)

- PLUS inclined conveyor belt