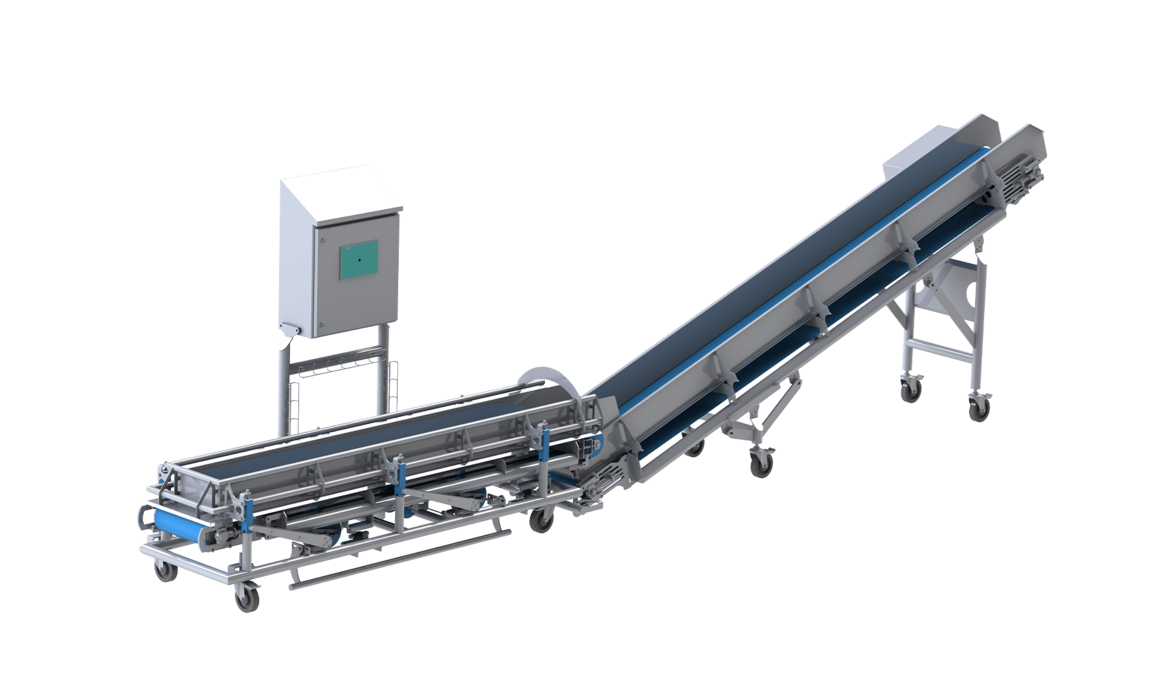

Batch weighing system

Weighing

An automated weighing system for putting together precise salad or vegetable blends based on a recipe. The mixtures are weighed in batches but continuously conveyed along the line to optimize processing efficiency.

10-100 kg (22-220 lb) / 30-300 kg (66-660 lb) per batch (small / large system) Max. capacity

- Features

- Specs

- Resources

Overview

A precise, automated batch weighing system for salad mixtures and vegetable mixtures – for continuous line processing

The automated Batch Weighing System from the KRONEN partner iWEIGH allows products containing cut vegetables, salad leaves, baby leaf lettuce and leafy vegetables to be mixed in batches according to a recipe before being conveyed to the next processing or packaging line.

The batches are continuously fed into the line to optimize its efficiency and prevent overfilling. The system weighs salad and vegetable mixtures up to an accuracy

of 200 g (.44 lb).

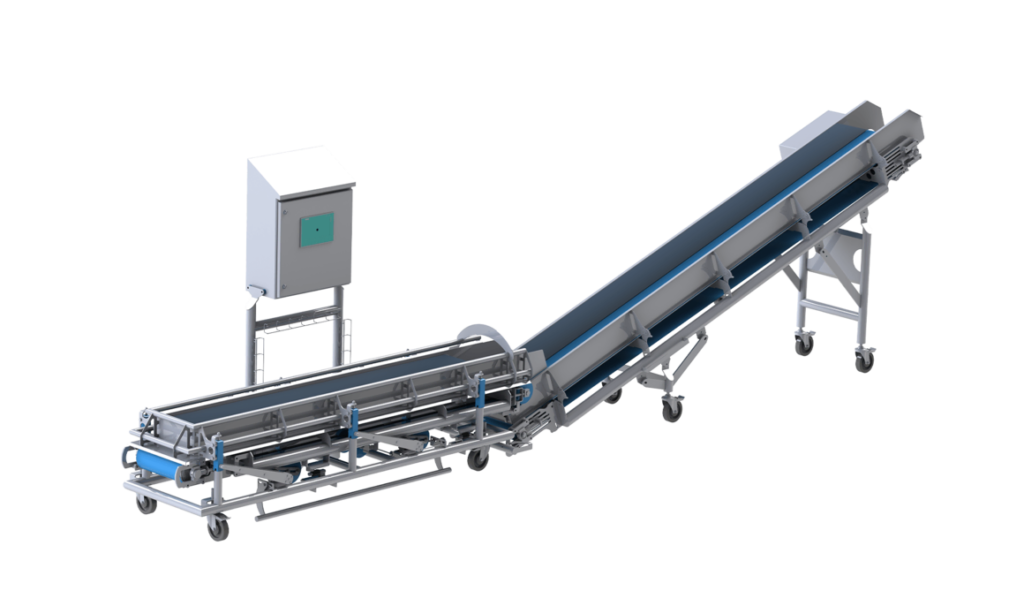

The weighing system comprises a recipe weighing conveyor and an inclined conveyor batch to flow, which feeds the product into the line.

A simple and user-friendly process

To use the recipe weighing system, the operator fills the weighing conveyor, which performs a dosing scale function, with the ingredients according to the clear instructions displayed on the touch panel. The recipe weighing belt is equipped with a tapping frame to ensure that crates of raw materials are fully emptied. Once the desired weight of the first ingredient has been added to the belt, the operator can confirm this using the foot bar, and the system then automatically moves on to the next ingredient. This process continues until the batch is complete.

The salad blend or vegetable blend is then automatically discharged onto the next belt so that the batch is distributed along the entire length of the belt. Once the discharge process is complete, the inclined conveyor batch to flow slows down in order to convey the batch into the system in a continuous flow, leaving the recipe weighing conveyor ready to receive the next batch.

A wide variety of flexible applications

The Batch Weighing System enables users to weigh up to 12 product components (cut vegetables, cut salad, baby leaf lettuce and leafy vegetables) according to pre-specified recipes. Up to 50 individual recipe mixtures can be stored using the touch panel, thus always ensuring up-to-date recipes and mixing ratios of a consistently high quality.

The robust system is designed especially for use in automated processing lines and can be optimally integrated into various process flows.

Your Benefits

- Precise mixing, fully recipe-based

- Precise production control with up to 3% precision

- Optimizes the efficiency of the processing line and prevents the line from being overloaded

- Durability, easy cleaning and simple maintenance thanks to a robust, open and hygienic design

- User-friendly and safe operation thanks to touch-panel visualization and operation

Highlights

Continuous, automated filling of the processing line

The mixed products are distributed along the entire length of the inclined conveyor batch to flow, which subsequently slows down. This allows the salad and vegetable mixtures to be fed into the line continuously, which in turn guarantees maximum efficiency and prevents the line from being overloaded.

Optimal maintenance and easy cleaning

The open and hygienic stainless steel design and the rods that hold up the belt enable easy cleaning.

Flexible designs can be ordered individually

Weighing belt systems can be optimally adapted to the individual specifications of different processing lines and also enable components to be added at different points during processing.

Specs

| Max. Capacity | 0-100 kg (22-220 lb) / 30-300 kg (66-660 lb) per batch (small / large system) |

| Loading Type | Semi-automatic |

| Electrical Power | Power: 1.5 kW (2 HP) Voltage: 400 V N/PE Frequency: 50 Hz |

| Dimensions | LxWxH: 3085 x 965 x 2005 mm (small system) or4632 x 1217 x 2005 mm (large system) –others available on request Weight: 200 kg (441 lb) (small system) or 400 kg (882 lb) (large system) Infeed/placement height: 800 mm (31.5″) Outfeed/placement height: 400 mm (15.8″) Belt width: 400 mm (15.8″) (small system) or 600 mm (23.6″) (large system) |

Industries

Vegetables

Fruit