Vortex

Disinfection

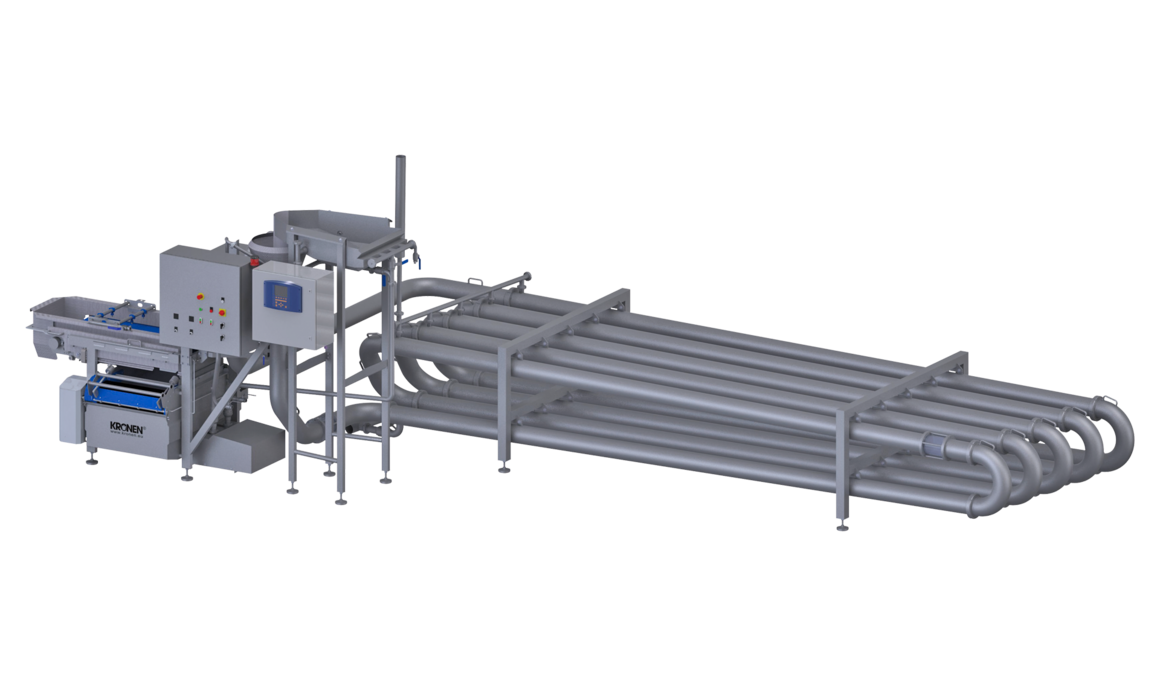

Bacteria reduction system for vegetable, salad, and fruit products. The Vortex ensures a defined retention time of the products in the wash water, during which the product is completely surrounded by water. As a result, washing additives reliably ensure reduction in bacteria load of the products.

up to 3,500 kg (7,716 lb)/h (with a retention time of 120 seconds) Max. capacity

- Features

- Specs

- Resources

Overview

Germ reduction due to a guaranteed retention time and complete rinsing of the product

The Vortex system disinfects cut or whole products such as whole carrots or even cut salad mixes with high capacity. For this purpose, a washing additive is used. In order for the additive to reliably achieve germ reduction on the products, the Vortex ensures complete rinsing of the products for a defined time.

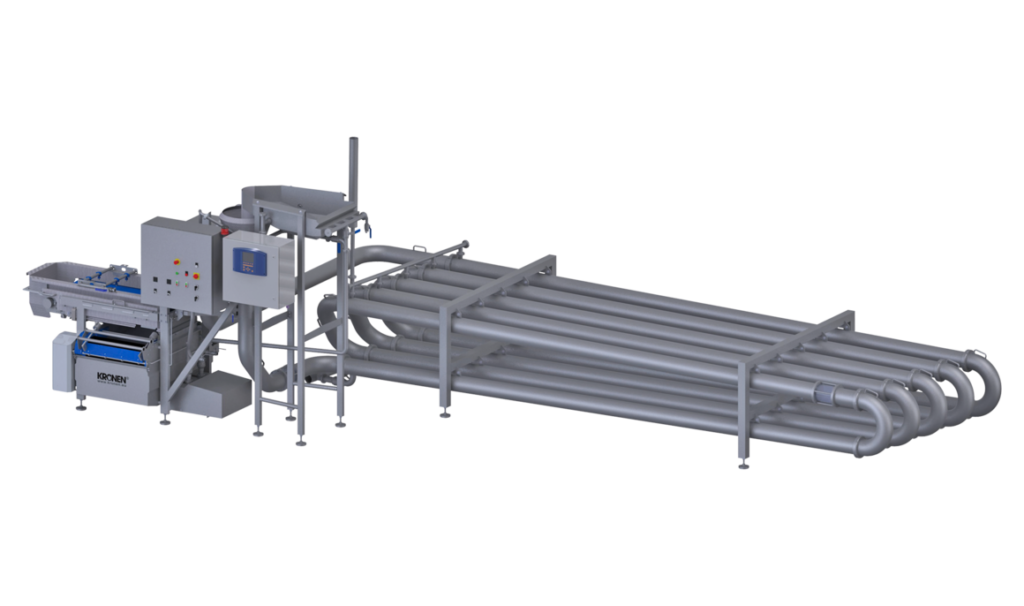

The products are flushed through the pipe system, which can be individually designed to meet customer requirements. The products are gently transported through the pipe system by the submergence channel without an active pump; the laminar water flow here is ensured by adjustable pumps.

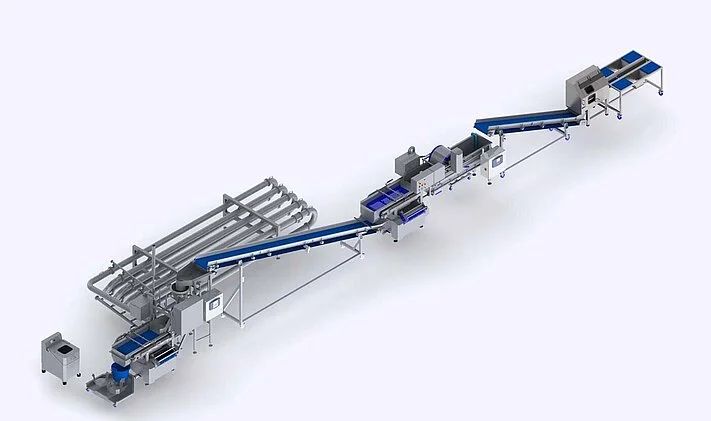

The combination of the Vortex with a GEWA washing machine enables an optimal washing result as the upstream GEWA ensures the removal of dirt and insects, and the downstream Vortex ensures treatment with a washing additive. The Vortex can also be optimally integrated into a continuous line setup.

The Vortex processes cut lettuce, for example, with a retention time of 120 seconds and a capacity of up to 3,500 kg (7,716 lb) per hour.

Your Benefits

- Controlled retention time in the wash water

- Product is completely surrounded by the wash water

- Flexible adjustment of the pipe for optimal integration into existing production facilities

- Pipe length can be designed according to customer requirements

Highlights

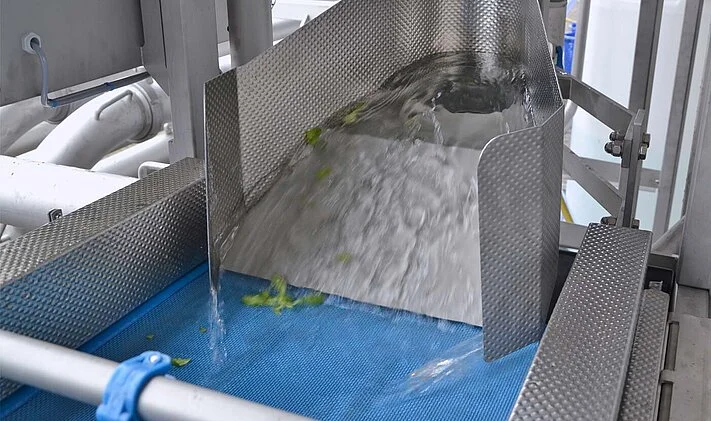

Submergence module for a reliable and gentle product infeed

The submergence flume ensures that the pre-washed product from an upstream washing machine is reliably and gently fed into the pipe system of the Vortex.

Efficient processing of large quantities

The pipe diameter of 200 mm enables the processing of large quantities. The products are not damaged when they flow through the pipe system.

Flexible pipe length for adjustment to meet customer-specific requirements

The pipe length primarily determines the contact time of the products with the washing additive and can be adjusted to meet customer-specific requirements.

Outfeed module: choice between belt and vibration outfeed

Depending on the product-specific requirements, the outfeed module can be equipped with a belt or vibration outfeed. A belt outfeed is suitable for delicate products such as baby leaf lettuce. With a vibration outfeed, additional dewatering of the products can already take place for less sensitive products such as whole carrots.

Easy to clean thanks to a modular pipe system

For easy cleaning, the pipe system is divided into sections that are accessible via milk pipeline fittings.

Specs

| Max. Capacity | up to 3,500 kg (7,716 lb)/h (with a retention time of 120 seconds) |

| Electrical Power | Power: 5.9 kW (8 HP) Voltage: 3~400 V N/PE Frequency: 50 Hz |

| Water | Fresh water connection: 3/4 inch (GEKA coupling) |

| Dimensions | LxWxH: Depending on configuration Weight: Depending on configuration Infeed/placement height: 2170 mm (85.4″) Outfeed/delivery height: 819 mm (32.2″) |

Industries

Vegetables

Fruit