AS 6 apple peeling and slicing machine

Cutting, Peeling

The multifunctional machine is optimized for peeling, coring, wedging and slicing apples – quickly, safely and for high capacities.

up to 900 apples/h Max. capacity

- Features

- Specs

- Resources

Overview

Maximum effectiveness and safety: perfectly peel, core and flexibly cut apples into segments and slices

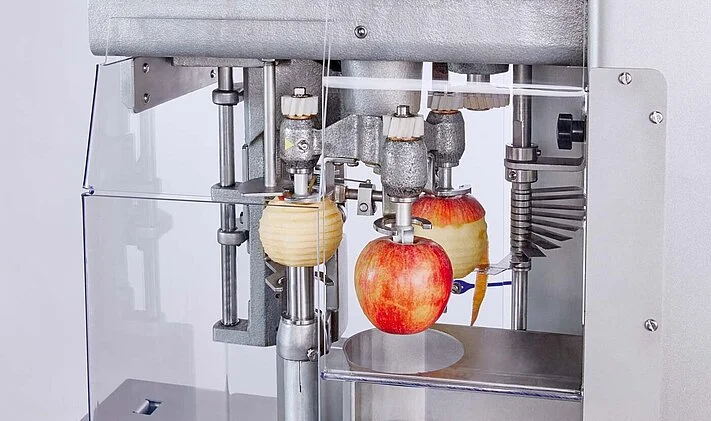

The AS 6 is a peeling, slicing and coring machine for apples used in the high-care sector of industrial processing. The apples only need to be inserted and are then skewered and processed completely automatically. The machine can process three apples at the same time. Therefore, a capacity of up to 900 apples per hour is achieved, which is equivalent to approximately 135 kg (300 lb) per hour (at 150 g/apple).

Processing in four steps:

- The apples are manually placed into the product intake and pneumatically skewered onto the fruit pocket.

- The apples are peeled and sliced if necessary.

- The core is removed and segments are cut in the same step if required.

- The finished end product is discharged separately from the waste.

Common uses:

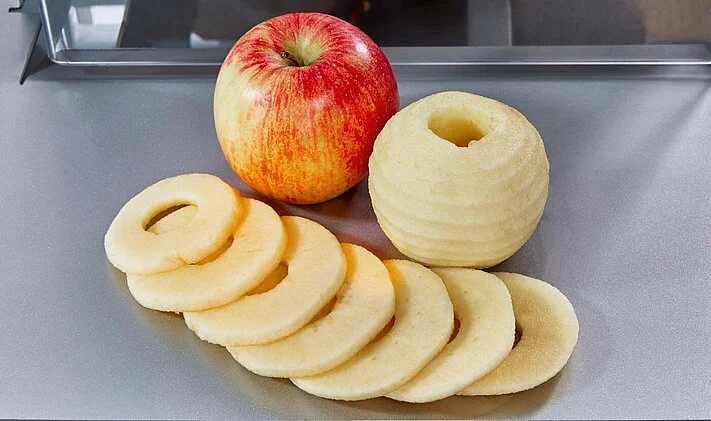

- Peeled tidbits, i.e. slices and segments, for example for bakery products or fruit salad

- Fresh segments for fresh-cut snacks, peeled or unpeeled

- Slices or rings for dried apple slices and rings, peeled or unpeeled

The machine processes whole apples with a diameter of 55 to 85 mm (2.2 to 3.3″) and a maximum height of 80 mm (3.1″). As standard, the AS 6 is equipped with two peeling knives and a cutting tube with a diameter of 23 mm (7/8″) with a scraper. In addition, a wide range of wedging knives, slicing knives, and cutting tubes are optionally available.

If apples are additionally to be cut into cubes, the KUJ V cube, strip and slice cutting machine is a good option.

Your Benefits

- Three applications: peeling, coring and slicing in one machine

- Automatic separation of good product and waste

- Safe, fast processing – apples only need to be inserted and are then automatically skewered

- Very high capacity – in addition, two machines can be operated by one user

- Large selection of cutting tools

- Can be combined with discharge conveyors for good product and waste product

Highlights

Increasing capacities

It is possible to set up several machines in parallel in order to further increase the capacity.

Integrated base frame for easy handling

The robust machine is placed on its own base frame. Simple, ergonomic operation and fast cleaning are thus guaranteed. The product outfeed into the hood integrated into the base frame takes place automatically.

Specs

| Max. Capacity | up to 900 apples/h (The capacity depends on factors such as the product.) |

| Operator | Semi-automatic Knife-peeling |

| Electrical Power | Power: 0.25 kW (.34 HP) Voltage: 1~230 V N/PE Frequency: 50/60 Hz |

| Air | Working pressure: 6 bar Air Consumption: 7 NL/min. |

| Dimensions | L x W x H: 861 / 1042 x 823 x 1715 mm (33.9 / 41 x 32.4 x 67.5″) (height without / with base frame) Weight: 163 kg (360 lb) Infeed/placement height: 1084 mm (42.7″) Outfeed/deliver height: 672 mm (26.5″) |

| Miscellaneous | Diameter of raw product: 55 – 85 mm (2.2 – 3.3″) Cycles per hour: up to 900 |

Industries