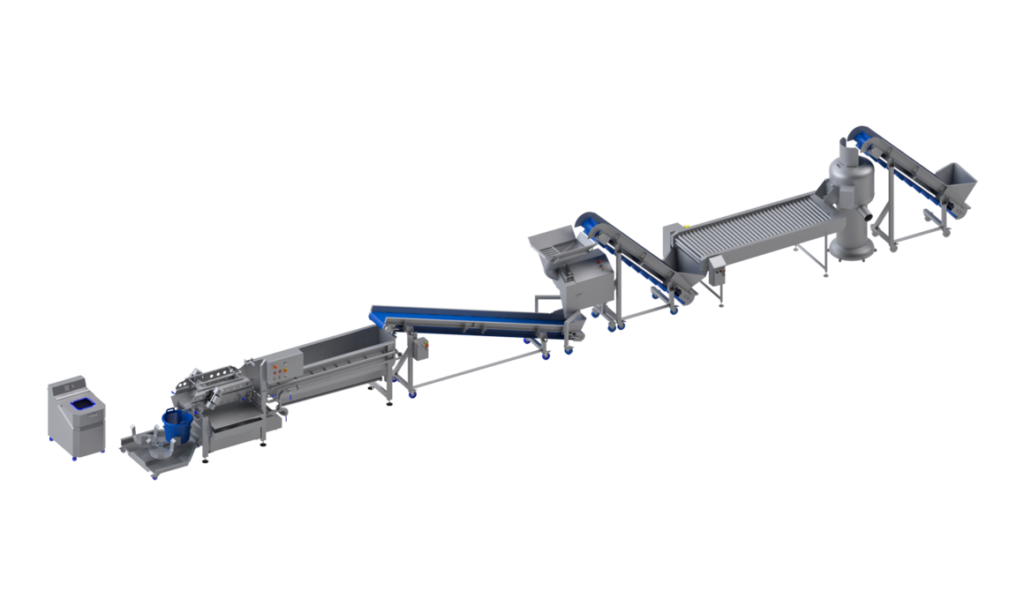

Processing line for potatoes – up to 600 kg/h

Peeling, Preparing, Cutting, Washing, Drying, Conveying

A semi-automatic entry-level system for peeling, preparing, cutting, washing and drying potatoes and other tuber vegetables, as well as for carrot processing: for more efficiency, gentle processing and high product quality – with high-quality machines that can also be used as stand-alone units.

Up to 600 kg (1,300 lb)/h max. capacity.

- Features

- Specs

- Resources

Overview

For peeling, trimming, cutting, washing and drying up to 600 kg (1,300 lb)/h of tuber vegetables

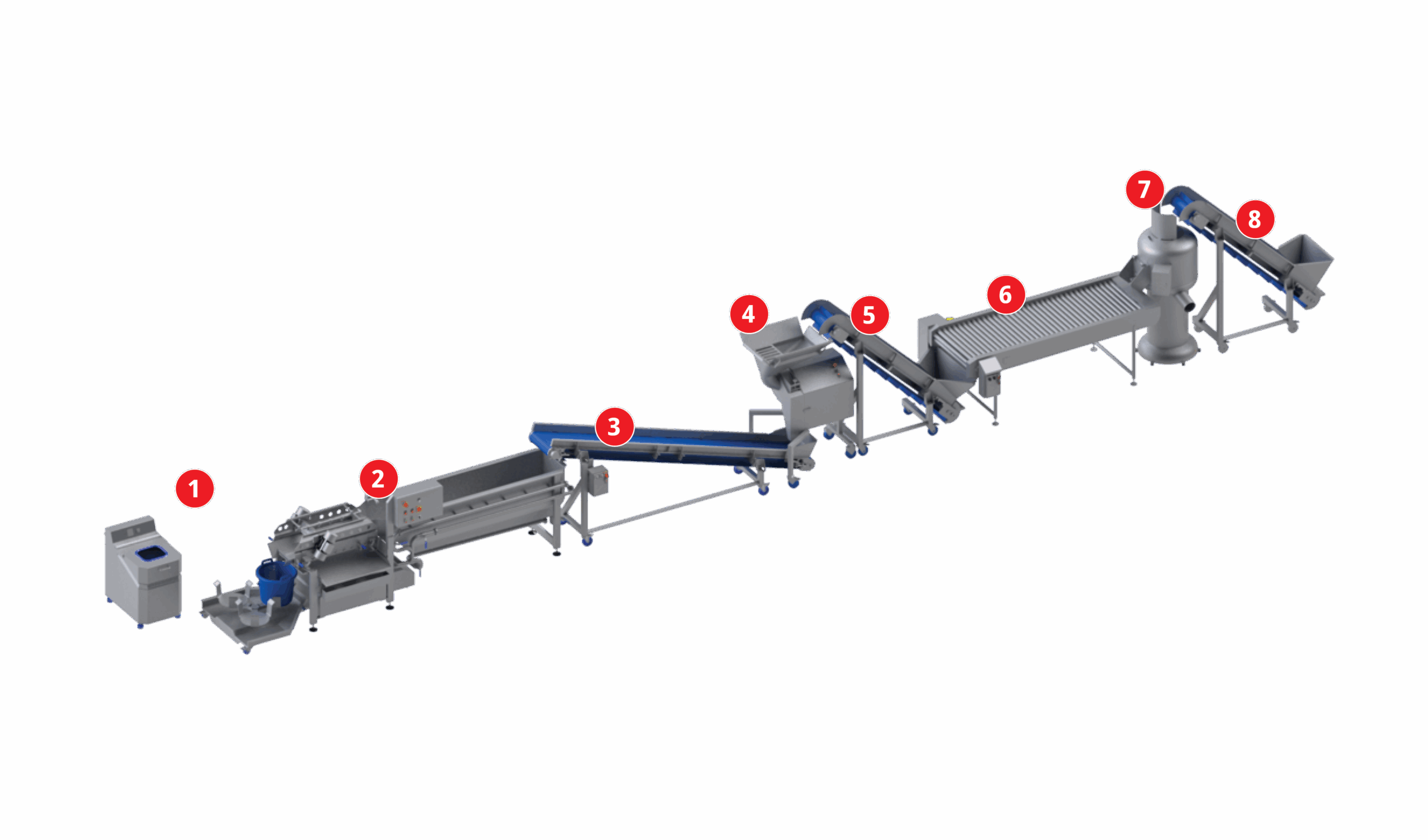

With the semi-automatic processing line, the product is transported to the peeling machine, peeled and then trimmed directly afterwards on the roller sorting table. It is subsequently automatically transported to the cutting machine, where it is cut and then forwarded to the washing machine. After the washing process, it is placed into spin baskets situated on a basket carousel. One person places the filled baskets into the spinners one after the other. The product can then be further processed.

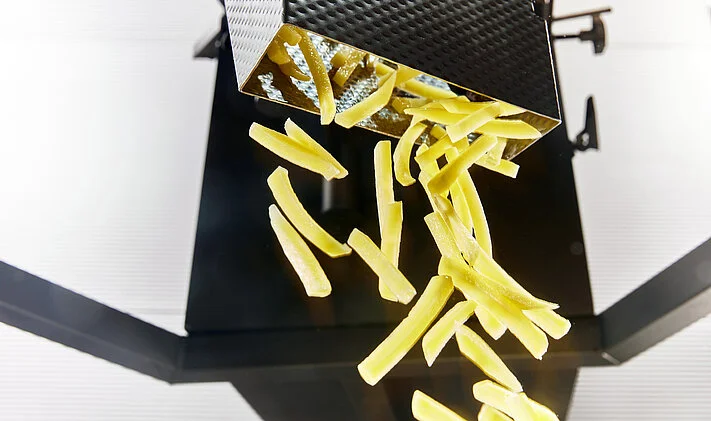

Excellent final results are achieved due to the exact and continuous cut with the KUJ-V, the professional preparation at the sorting table and the effective yet gentle washing and spinning.

The following machines or solutions are integrated into the line:

- Conveying: PLUS inclined conveyor belt with cleats

- Peeling: PL 40K potato peeling machine with different abrasive grain sizes, an optional peel collector and a peeling basket reinforced with a perforated plate

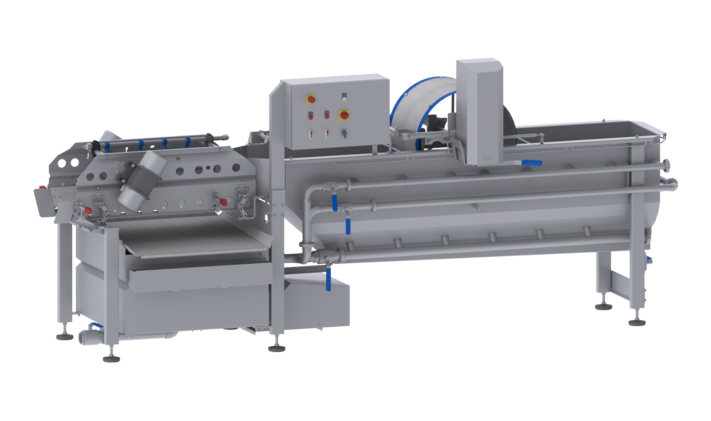

- Preparation: RVT 20/25 roller sorting table

- Conveying: PLUS inclined conveyor belt with cleats

- Cutting: KUJ-V cube, strip & slice cutting machine, optionally with various cutting inserts

- Conveying: PLUS inclined conveyor belt

- Washing: GEWA 3800 ECO HELICAL washing machine with vibration outfeed and an optional measuring and dosing system or UVC water reactor.

- Drying: KS-100 PLUS with a basket carousel

Application options and capacities:

The line processes up to 600 kg (1,300 lb) of product per hour. It is used for the abrasive peeling and preparation of tuber vegetables including potatoes, carrots, beets and celery. The products can then be further processed – whole or cut – for example packaged as packed raw, blanched, cooked or frozen products.

The raw products are processed whole. Only long products such as carrots or radishes should be previously cut into two or three parts to achieve a perfect peeling result. The diameter of the product should not exceed 150 mm (5.9″).

Pumpkins and squashes cannot be processed on this line. The line can be optionally offered with the AMS 220 peeling machine for flat pumpkins.

Your Benefits

- Semi-automatic processing for increased efficiency in production

- High-quality machines that can also be used as stand-alone units: PL 40K, KUJ-V, GEWA 3800 ECO and KS-100 PLUS, among others.

- Gentle processing and high product quality

- Simple operation without complex overall control

- Can be extended at any time to accommodate higher capacities and to meet individual requirements

Highlights

Automatic, hygienic and flexible processing

The KRONEN cutting, washing and drying machines are also designed for frequent product or recipe changes during a production shift. The belt cutting machines guarantee quick knife replacement. The washing machines fully empty in a very short time. The drums of the large centrifuges are blown dry during emptying. The hygienic design of the KRONEN machines allows all areas to be easily accessed and makes the machines easy to clean. User-friendly operation and the safety of operating personnel are guaranteed.

Complete solutions from a single source

KRONEN is a reliable partner, even when it comes to implementing automated processing lines. With a high level of planning and consulting expertise, the company implements the right solution for every customer requirement. KRONEN offers complete lines from a single source and integrates suitable machines from partners as required.

Specs

| Max. Capacity | up to 600 kg (1,300 lb)/h |

| Operator | Semi-automatic |

| Miscellaneous | Abrasive peeling |

| Sanitation | Wet disinfection |

| Loading Type | Batch |

- KS-100 PLUS vegetable and lettuce spin-dryer with a basket carousel

- GEWA 3800 ECO with vibration outfeed

- PLUS inclined conveyor belt

- KUJ-V cube, strip and slice cutting machine

- PLUS inclined conveyor belt with cleats

- RVT 20/25 roller sorting table

- PL 40K potato peeling machine

- PLUS inclined conveyor belt with cleats

Industries