Comitrol® Processor Models 3600 - 3675SL

Small Volume to High Capacity Environments

- Common applications include rework of bakery items, beef/poultry/seafood and byproducts, and vegetables/fruits.

- The Comitrol Processor Models 3600, 3640, 3660, and 3675 are designed for low to high capacity production environments.

- Each model varies in dimension, height, weight, and horsepower.

- Each model features continuous operation for uninterrupted production and simplified design to ease cleaning and maintenance.

- Processors benefit from a wide selection of interchangeable cutting heads and impellers for diverse applications such as chopping, flake cutting, granulating, pureeing, and emulsifying.

Applications

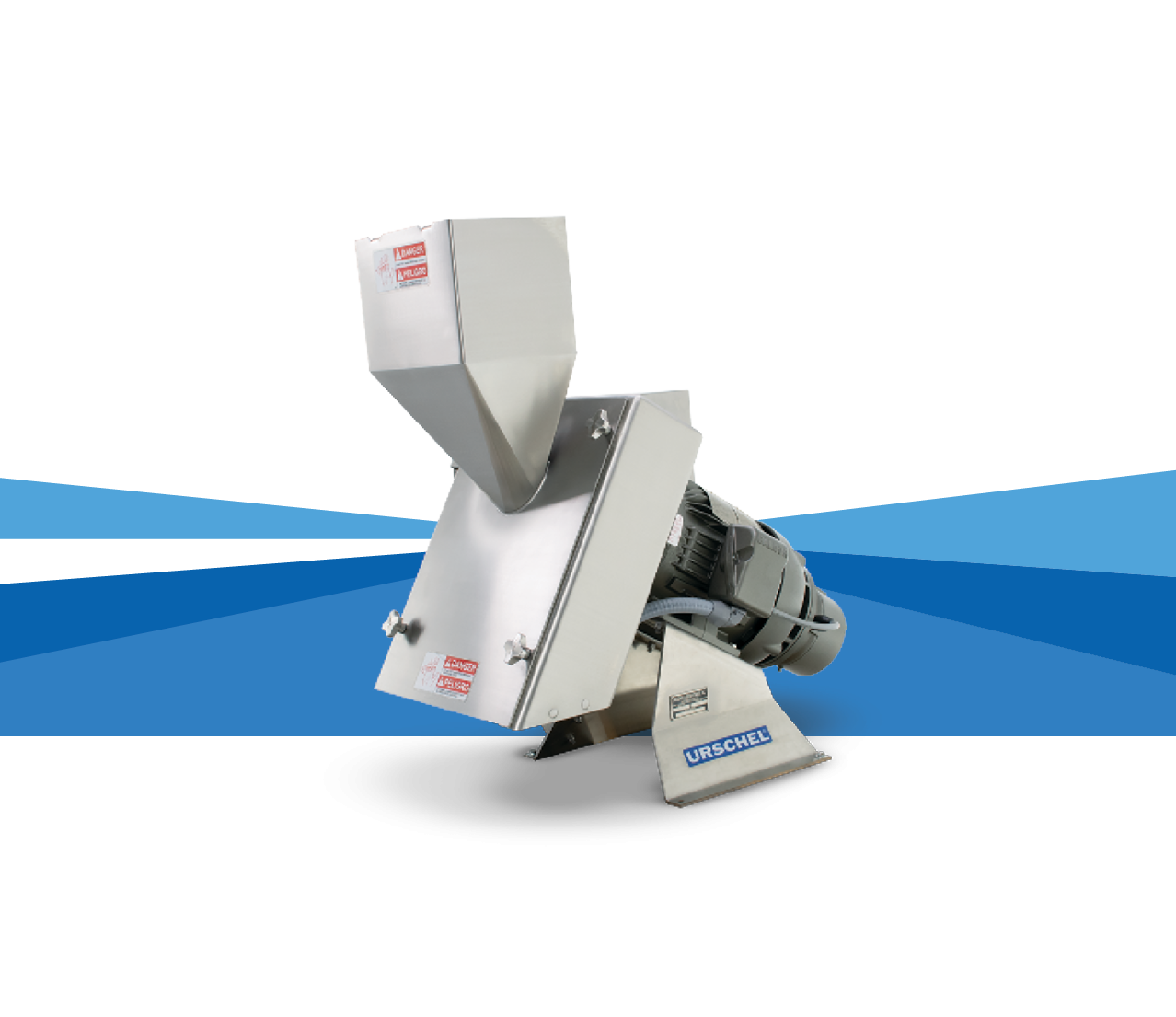

The Model 3600 Slant is popular in both small volume and large-scale production environments. The 3600 Slant is equipped with a 10 HP (7.5 kW) impeller motor for speeds up to 3600 RPM. The gravity fed machine offers a compact size. The machine is often used as a pre-cutter in conjunction with a Comitrol Processor Model 1500 or 1700. Common applications include rework of bakery items, beef/poultry/seafood and byproducts, and vegetables/fruits.

Stainless steel construction ensures maximum durability and sanitation. The machine features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance. Product input is dependent on the style of reduction head, impeller selection, and spacing within the head. Generally, maximum input size in any dimension should not exceed 2-1/2" (63.5 mm).

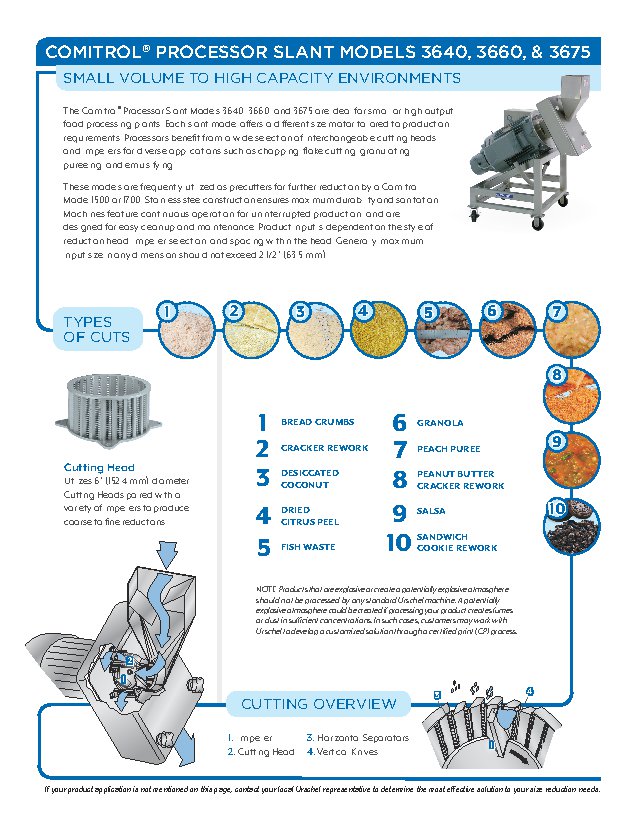

The Comitrol® Processor Slant Models 3640, 3660, and 3675 are ideal for small or high output food processing plants. Each slant model offers a different size motor tailored to production requirements. Processors benefit from a wide selection of interchangeable cutting heads and impellers for diverse applications such as chopping, flake cutting, granulating, pureeing, and emulsifying.

Machine Specs

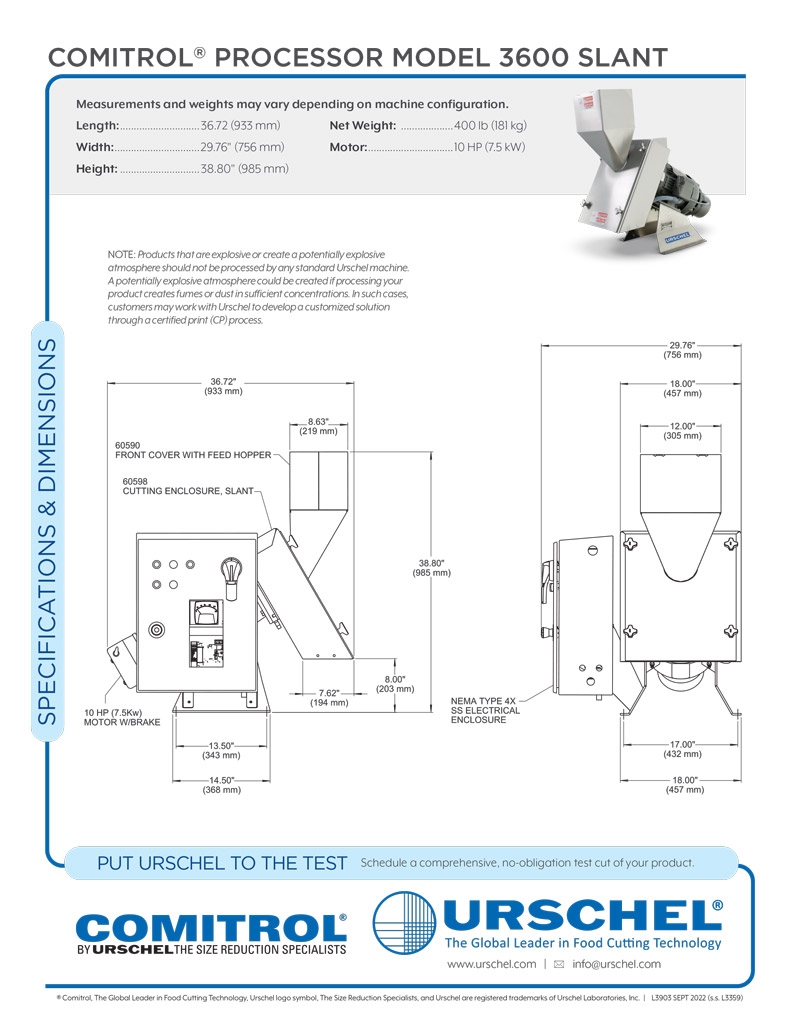

Comitrol Processor Slant Model 3600

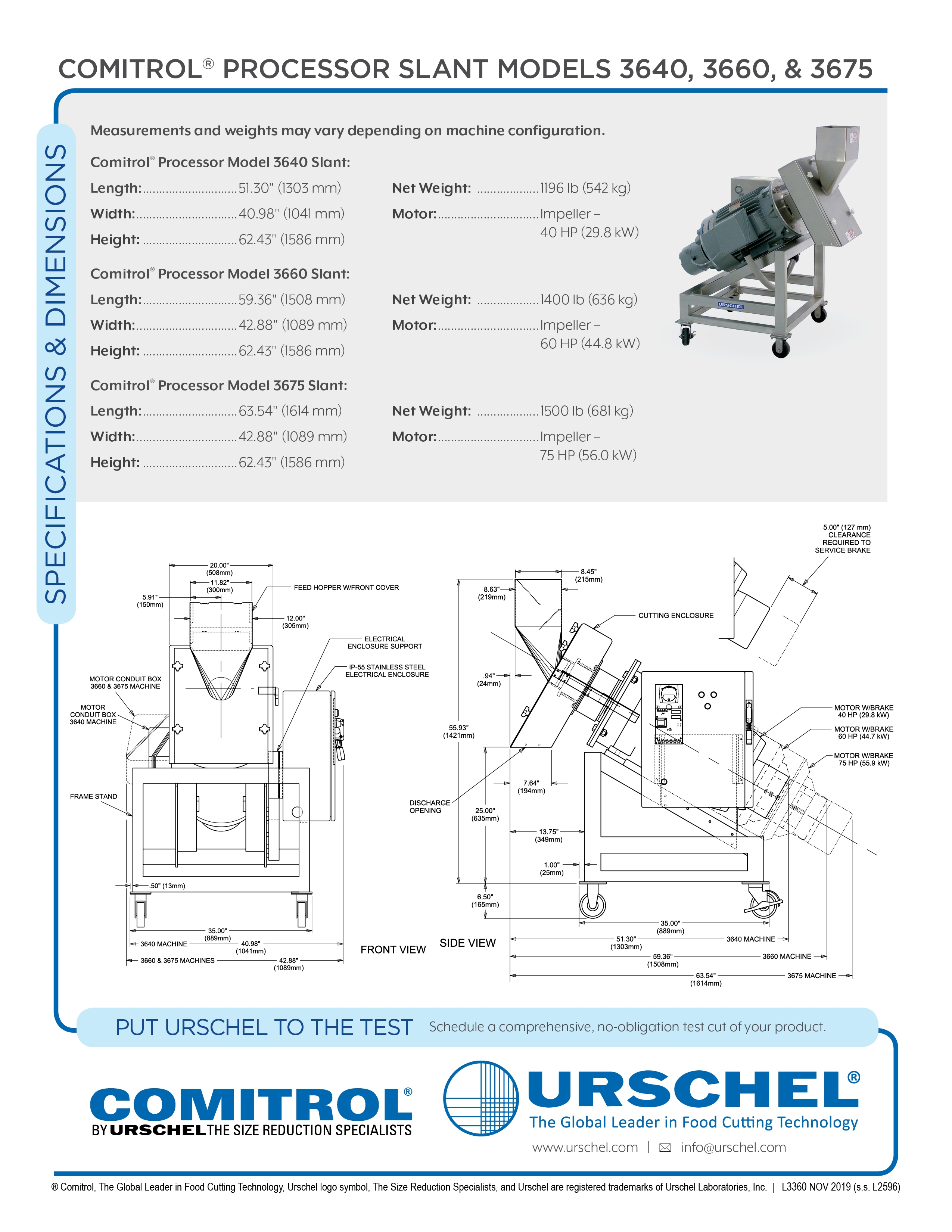

Comitrol Processor Slant Models 3640, 3660, and 3675

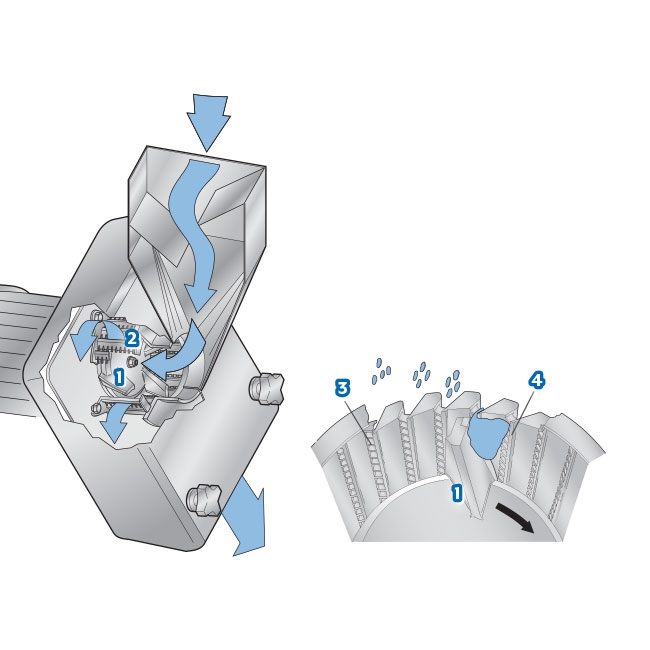

Operating Principle

Comitrol® Processor Models 3600 - 3675SL

- Impeller

- Cutting Head

- Horizontal Separators

- Vertical Knives

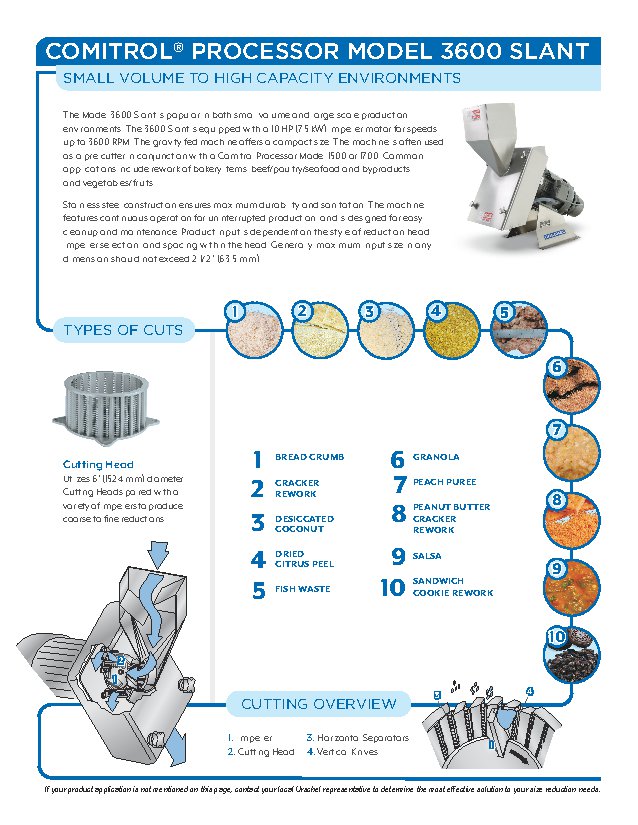

Types of Cuts

Cutting Head

Utilizes 6" (152.4 mm) diameter Cutting Heads paired with a variety of impellers to produce coarse to fine reductions.

NOTE

Products that are explosive or create a potentially explosive atmosphere should not be processed by any standard Urschel machine. A potentially explosive atmosphere could be created if processing your product creates fumes or dust in sufficient concentrations. In such cases, customers may work with Urschel to develop a customized solution through a certified print (CP) process.