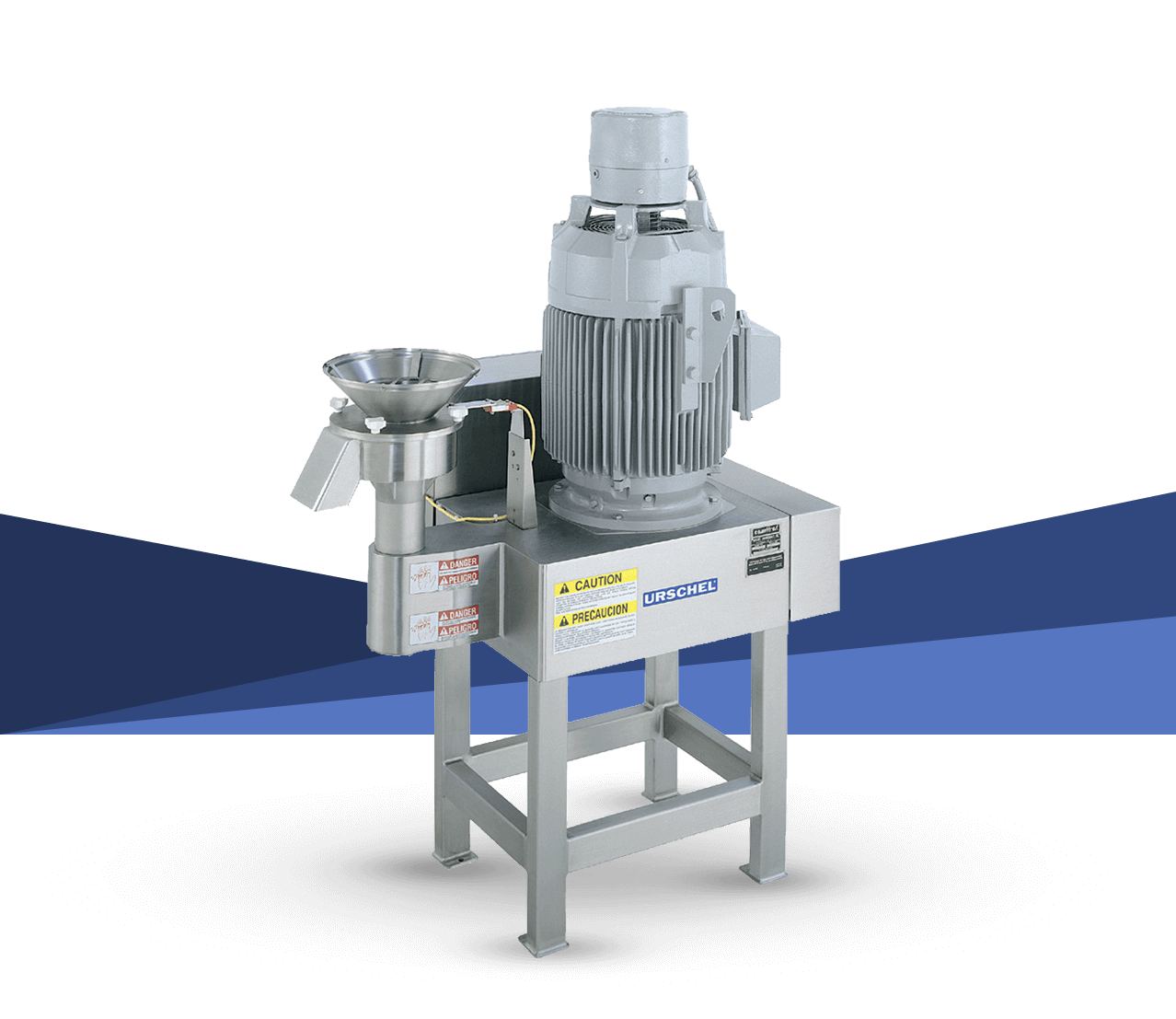

Comitrol® Processor Model 3000

High Moisture Content Applications

- Ideally suited for milling products with a high moisture content such as vegetables and cooked meats.

- The two piece enclosure simplifies disassembly, cleaning, and care of the cutting parts.

- Available 15, 30, or 40 HP (11.2, 22.4, or 30 kW) motor.

- Features continuous operation for uninterrupted production and simplified design to ease cleaning and maintenance.

Applications

The Comitrol Processor Model 3000 is ideally suited for milling products with a high-moisture content such as whole kernel sweet corn, cooked meats, and vegetables. Product input is dependent on the style of reduction head, impeller selection, and spacing within the head. Generally, maximum input size in any dimension should not exceed 2-1/2" (63.5 mm).

The two piece enclosure simplifies disassembly, cleaning, and care of the cutting parts. Stainless steel construction ensures maximum durability and sanitation. The machine features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance.

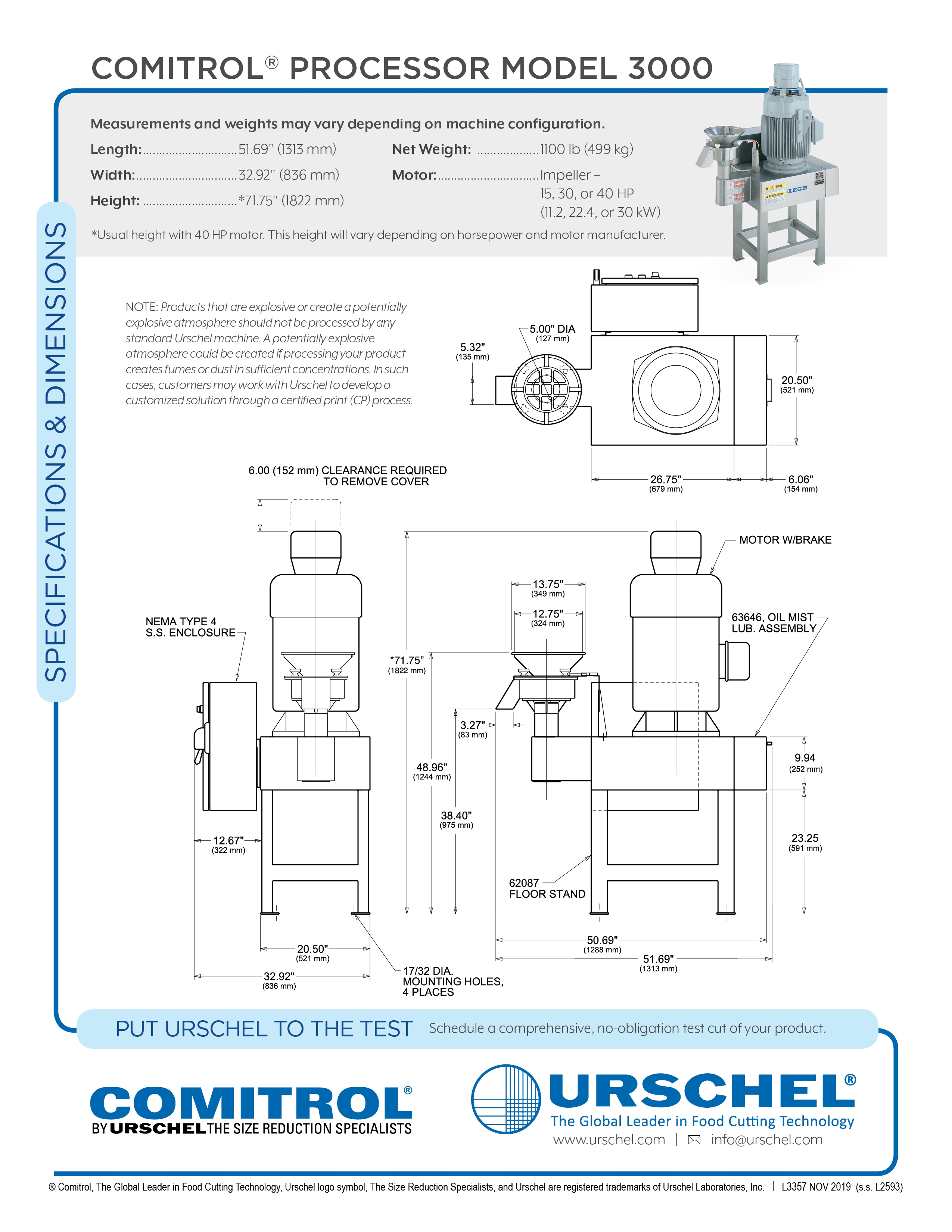

Machine Specs

* USUAL HEIGHT WITH 40 H.P. MOTOR IS SHOWN. THIS HEIGHT WILL VARY DEPENDING ON HORSEPOWER AND MOTOR MANUFACTURER. CONSULT URSCHEL LABORATORIES, INC. TO DETERMINE SPECIFIC HEIGHT.

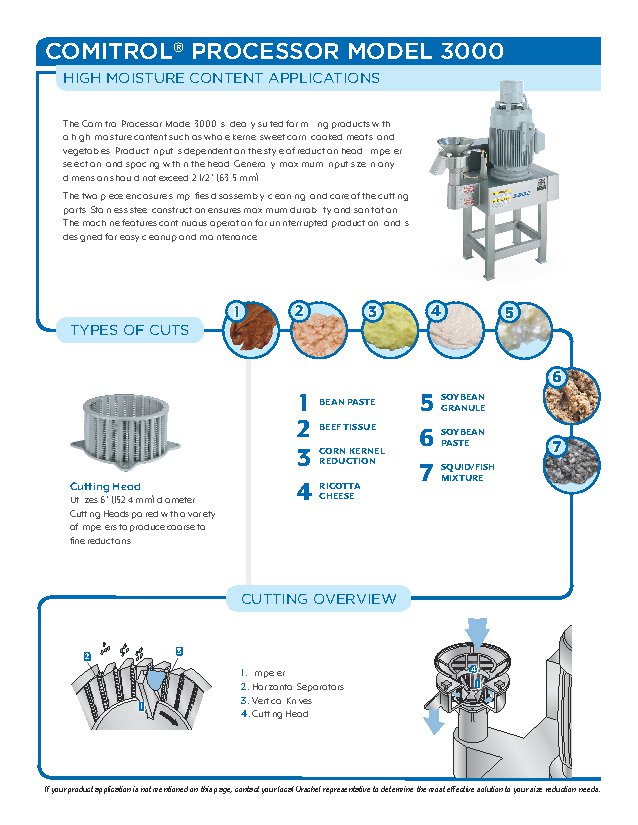

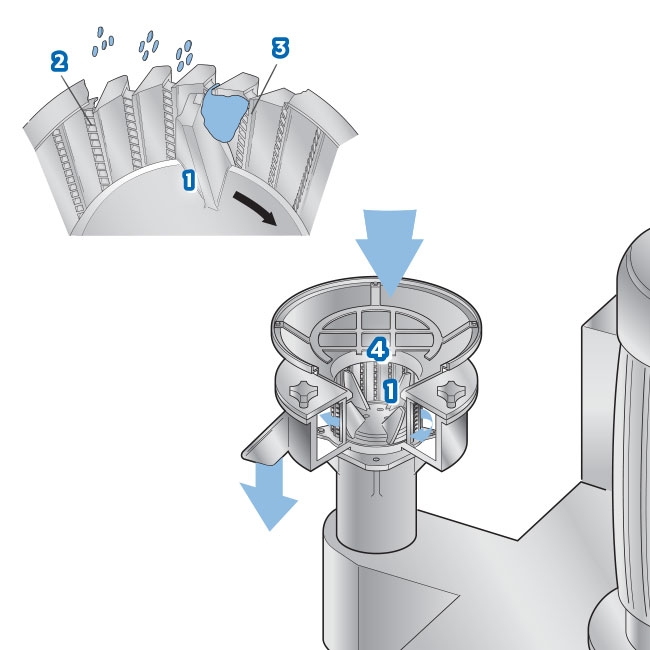

Operating Principle

Comitrol® Processor Model 3000

- Impeller

- Horizontal Separators

- Vertical Knives

- Cutting Head

Types of Cuts

Cutting Head

Utilizes 6" (152.4 mm) diameter Cutting Heads paired with a variety of impellers to produce coarse to fine reductions.

NOTE

Products that are explosive or create a potentially explosive atmosphere should not be processed by any standard Urschel machine. A potentially explosive atmosphere could be created if processing your product creates fumes or dust in sufficient concentrations. In such cases, customers may work with Urschel to develop a customized solution through a certified print (CP) process.